page 8 Compass

™

Stainer Operator’s Manual

Compass Stainer System Hazards

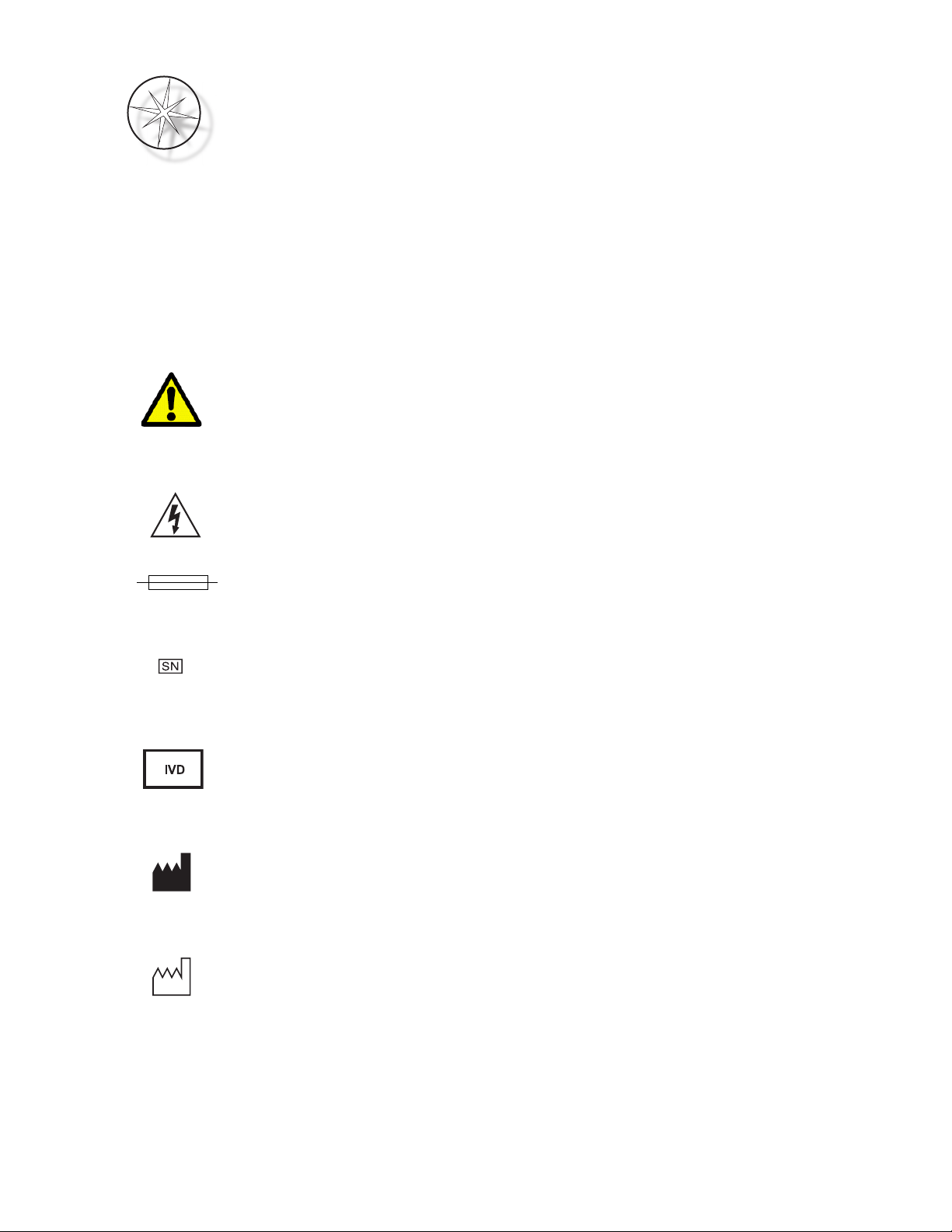

Symbols Used On the Instrument

Symbol Title Description Standard Information

Caution

To indicate that caution is nec-

essary when operating the

device or control close to where

the symbol is placed, or to indi-

cate that the current situation

needs operator awareness or

operator action in order to avoid

undesirable consequences

ISO 7000 Graphical symbols for

use on equipment, symbol

0434B

Caution, risk of electric

shock

To identify equipment that has

risk of electric shock

IEC 60417 Graphical symbols

for use on equipment, symbol

5042

Fuse To identify fuse boxes or their

location.

IEC 60417 Graphical symbols

for use on equipment, symbol

5016

Serial number

Indicates the manufacturer’s

serial number so that a specific

medical device can be identi-

fied.

ISO 15223-1 Medical devices—

Symbols to be used with medi-

cal device labeling and informa-

tion to be supplied, Section

5.1.7

In vitro diagnostic medi-

cal device

Indicates a medical device that

is intended to used as an in vitro

diagnostic medical device

ISO 15223-1 Medical devices—

Symbols to be used with medi-

cal device labeling and informa-

tion to be supplied, Section

5.5.1

Manufacturer

Indicates the medical device

manufacturer, as defined in the

EU Directives 90/385/EEC, 93/

42/EEC and 98/79/EC

ISO 15223-1 Medical devices—

Symbols to be used with medi-

cal device labeling and informa-

tion to be supplied, Section

5.1.1

Date of manufacture

Indicates the date when the

medical device was manufac-

tured

ISO 15223-1 Medical devices—

Symbols to be used with medi-

cal device labeling and informa-

tion to be supplied, Section

5.1.3