HUVF SERIES DUCT MOUNTED UV SYSTEM

531-00455—01

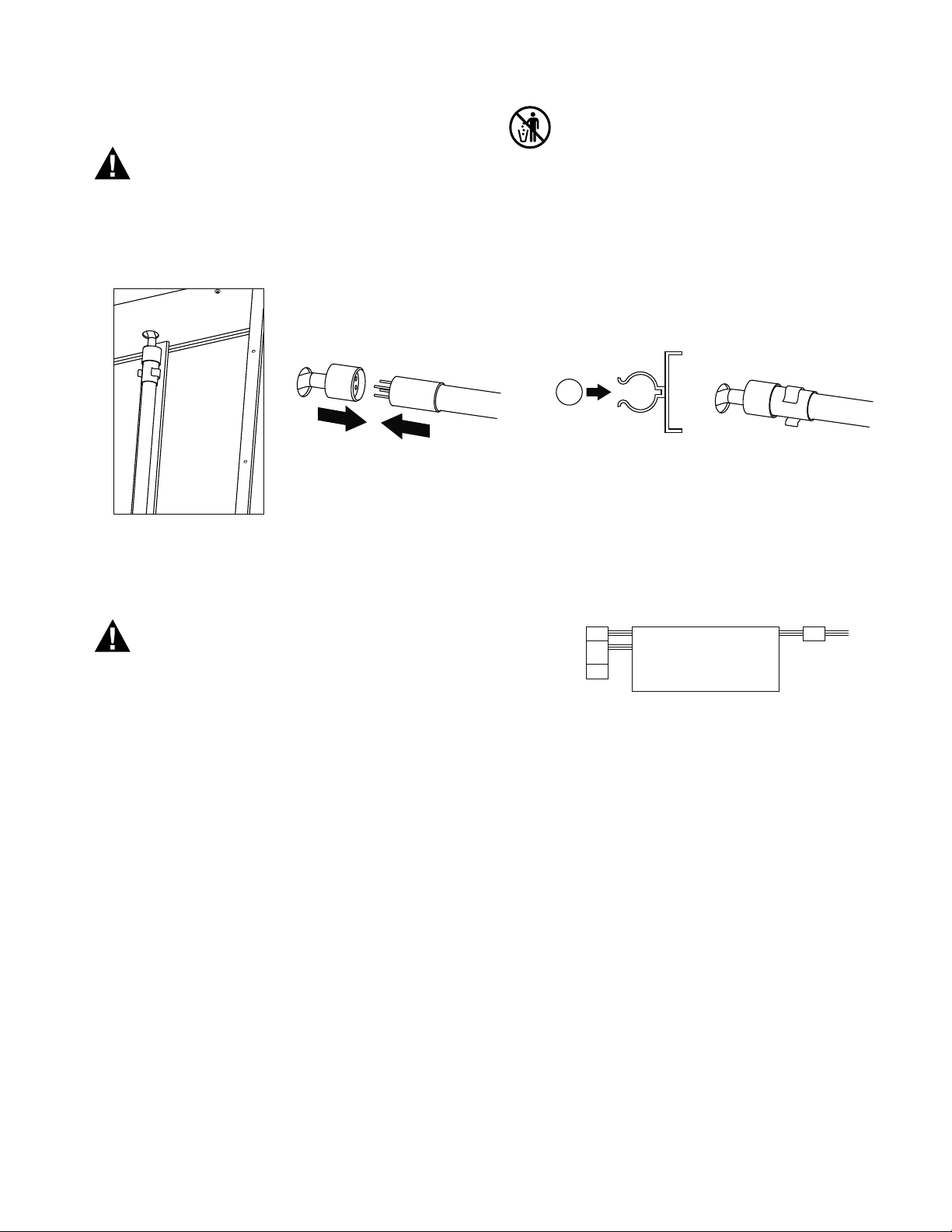

Connect the Lamps

Breakable Glass Hazard.

Can cause personal injury.

Be careful when inserting bulb(s) into lamp base.

Wear protective gloves when handling the bulb(s).

This device contains mercury in the sealed

ultraviolet bulb(s). Do not place your used bulb(s) in

the trash. Dispose of properly.

Make sure that the UV lamp is connected properly to the

4-pin holder and is fixed in the clamps provided on the

reflector as shown in Fig. 7 below.

Fig. 7. Bulb connection.

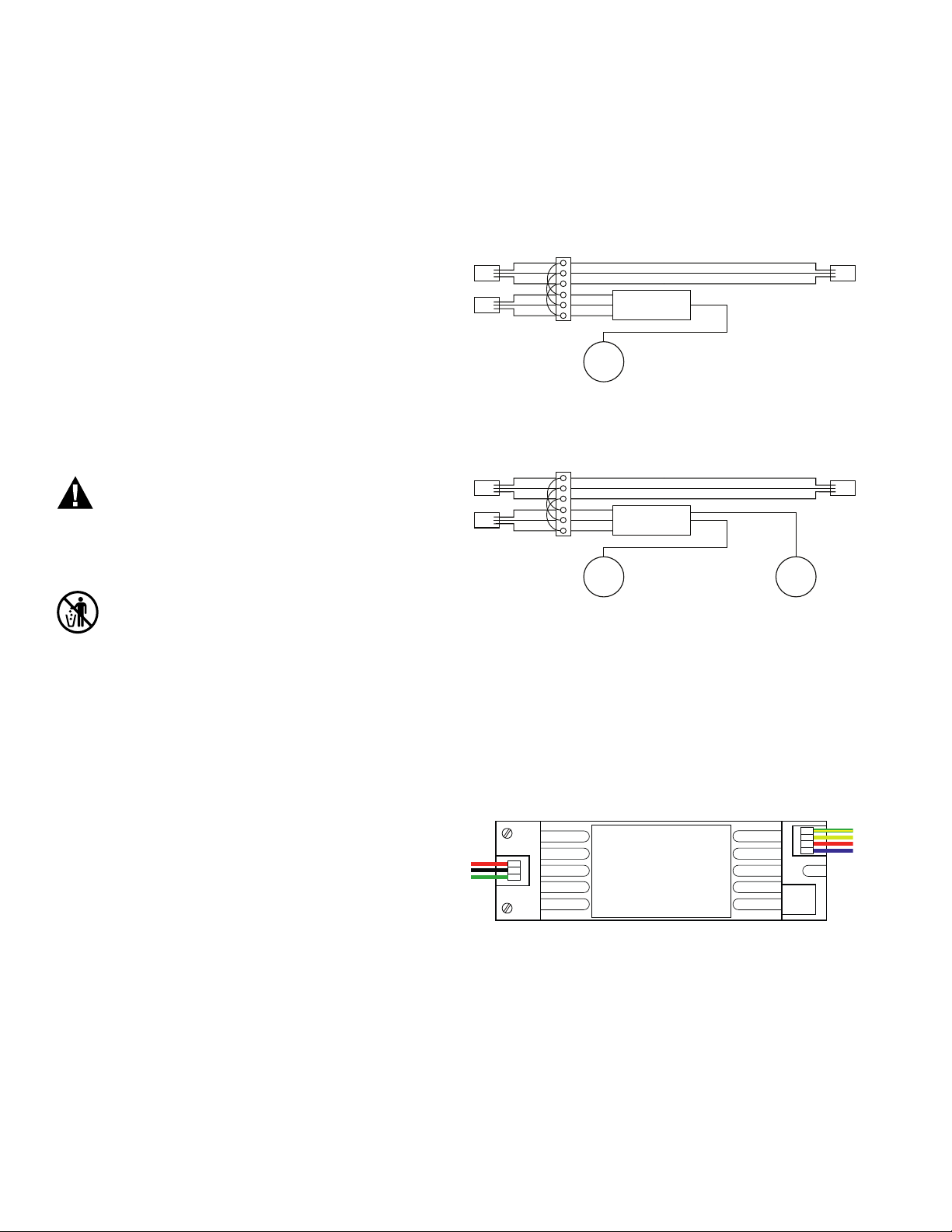

WIRING

Main power supply must be secured with

interlock on the AHU door.

The electrical supply circuit connected to this UV

appliance must be routed through an electrical

interlock switch placed on the HVAC system duct

access panels and doors to prevent accidental UV

exposure when servicing the air ducts or

equipment. Interlock shall break all supply

conductors.

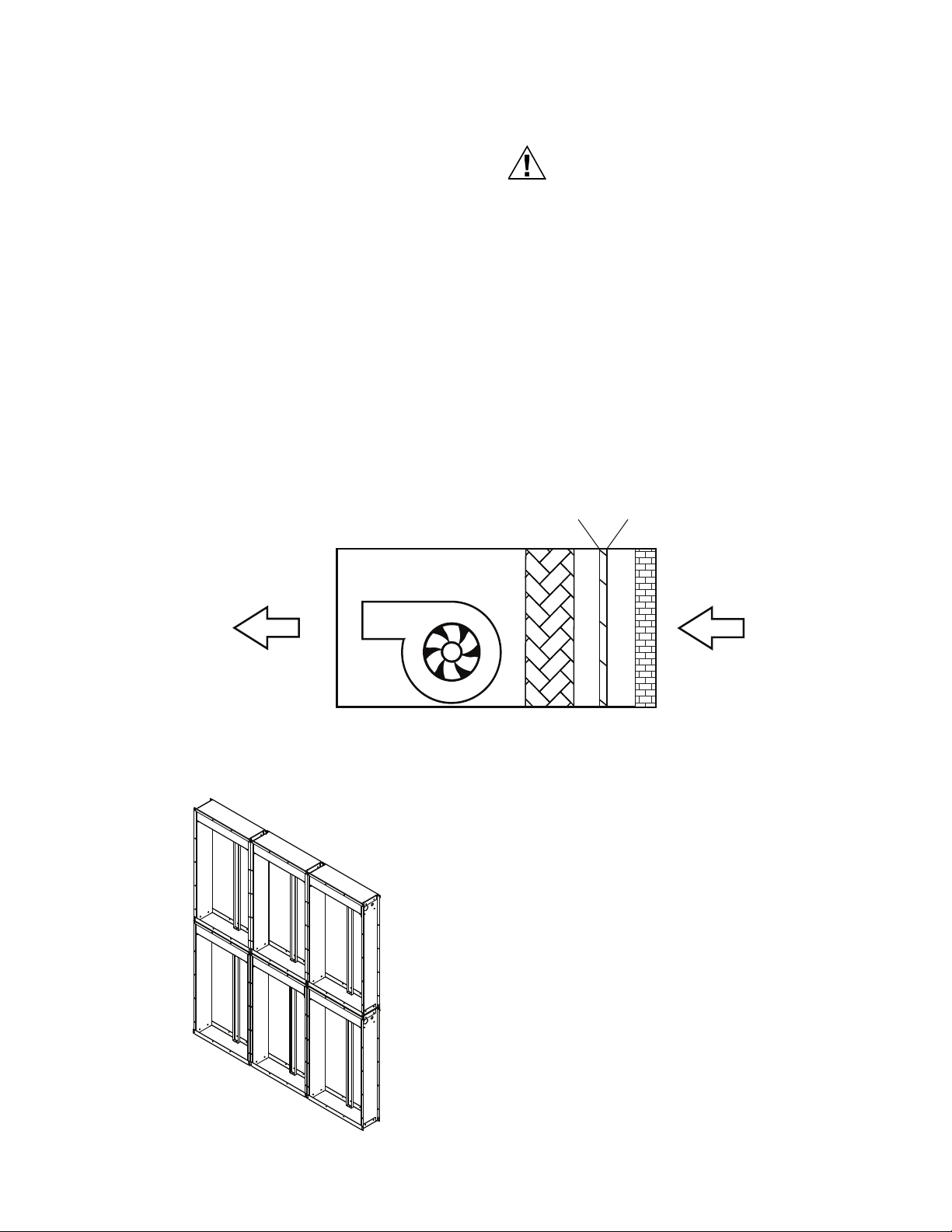

• Power supply wiring system shall provide a

disconnect switch for all poles.

• Assure all wiring complies with local codes and

ordinances.

• Wire the UV system directly to the correct voltage

and frequency electrical source. See Fig. 8.

• Install extension box, with cover, for all external

plugs and wiring connections.

• This appliance incorporates an earth connection

for functional purposes only.

Power Connections

1. Decide which end of the installed array is most acces-

sible for wiring.

2. Cut off the plastic connector for each row of air

cleaners on the end selected.

3. Install a extension box to the end of each row of air

cleaners.

4. Connect power and ground leads to each row of air

cleaners.

5. Install cover on each box.

6. Install box and cover over power connector on oppo-

site end of each row.

Fig. 8. Power connection to HUVF.

OPERATION AND

MAINTENANCE

NOTICE:

• Service of the product to be done by authorized

representative only

• Operated and serviced by qualified personnel

• No interlocks under any circumstance are defeated

• All safety measures recommended are followed as

prescribed

• Provided all control measures are implemented at the

user site for safety as per the Risk analysis document.

• Any internal part of the assembly shall not be removed

for independent use for other applications.

During normal operation make sure that the electrical

supply circuit connected to this UV appliance must be

routed through an electrical interlock switch placed on the

HVAC system duct access panels and doors to prevent

accidental UV exposure when servicing the air ducts or

equipment” or equivalent. “Interlock shall break all supply

conductors.

Power Input

Adjacent System F

MM

M = Male Connector

F = Female Connector

Adjacent

System

HUVF58C1000 / HUVF58C2000

HUVF58S1000 / HUVF58S2000