10

Mousse Coupe-Feu CP660

Mode d'emploi

La mousse coupe-feu CP660 est utilisée en tant que calfeutrement coupe-feu pour des applications à l'in-

térieurdesimmeubles. La mousse est destinée au calfeutrage de botte de câbles, chemins de câbles,

tuyaux/buses combustibles/non combustibles dans des passages de petites à moyennes dimensions tant

dimensions dans des murs ou plafonds coupe-feu.

Lesdispositionsrelativesàl'agrémentdoiventêtrerespectées.Uniquementpourl'utilisateurprofessionnel.

L'agrémentetlachededonnéestechniquespeuventêtreobtenusauprèsde votre contactHilti local.

Stockerdanssonemballageferméàl'abridel'humidité.

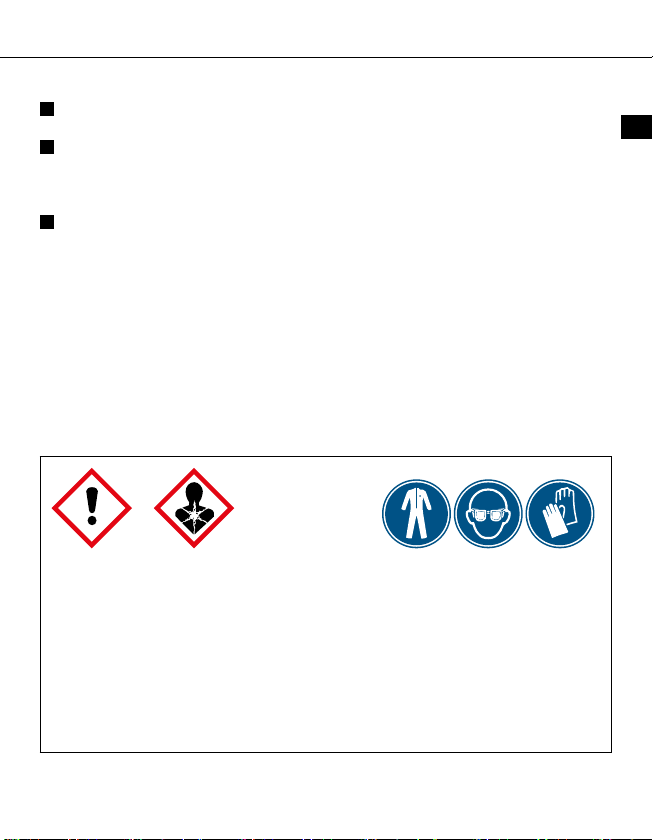

Avanttouteutilisation,bienlireleprésentmoded'emploiainsiquelesdirectivesdesécurité.

Datedepéremption:voir la date imprimée sur le raccord de la cartouche (JJ/MM/AA). Ne plus utiliser les

recharges dont la date de péremption est dépassée.

Transportetstockage:conserver dans un endroit frais, sec et à l'abri de la lumière, à une température

comprise entre +5°Cet+25°C.

Températuredesrecharges: doit être comprise entre +10°Cet+35°C lors de l'utilisation.

Températuredumatériausupport: doit être comprise entre 0°Cet+40°C lors de l'utilisation.

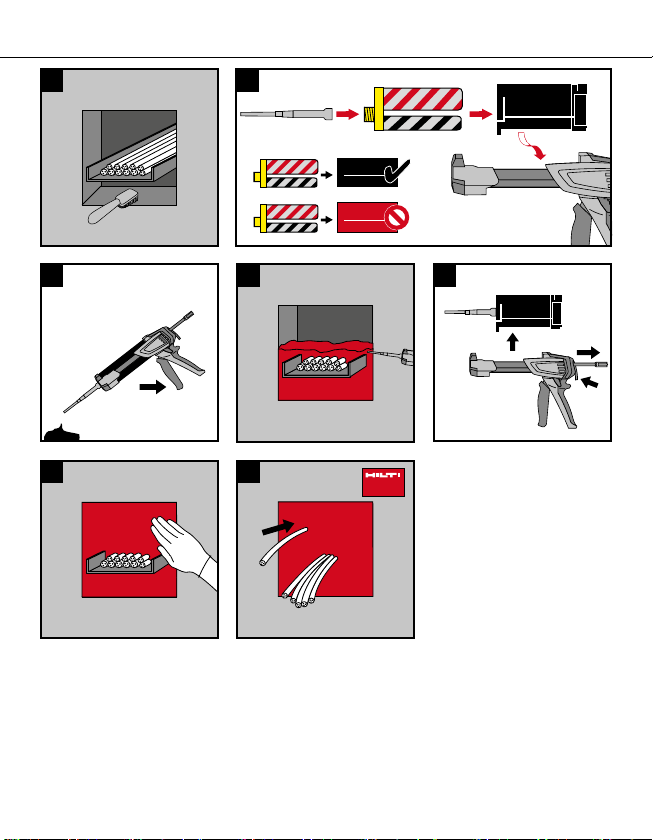

Instructionsdemontage:illustration de la séquence des étapes : voir pictogrammes 1 à 7 / 3

1Nettoyerl'ouvertureàobturer.L'ouverture doit être solide, sèche, exempte de poussière et de graisse.

2 Vérier que le porte-cartouches n'est pas endommagé et qu'il fonctionne correctement. Insérer la

rechargedansleporte-cartouches.Attention!Ne jamais utiliser de recharges endommagées ni de

porte-cartouches endommagés/très encrassés.

Oter le capuchon de fermeture. Vissercomplètementetfermementl'emboutmélangeurdelarecharge.

Vérier qu'il y a bien du composant noir à l'intérieur ! Ne pas utiliser de mélangeur endommagé. Ne

modier la buse mélangeuse en aucun cas. L'embout mélangeur de la recharge doit uniquement être

utilisé avec le mélangeur joint. Un nouveau mélangeur doit être utilisé pour chaque nouvelle recharge.

Insérerleporte-cartouchesaveclarechargedanslepistoletapplicateur:appuyer sur le bouton de

déblocage du pistolet applicateur, retirer la tige d'amenée jusqu'en butée. Insérer ensuite le porte-car-

touches avec la recharge dans le pistolet applicateur

3La recharge s'ouvre automatiquement lors de l'application. Ne jamais percer activement l'emballage –

cela causerait une défaillance du système !

Jeterlesamorcesnonhomogènes:le premier coup d'amorce sortant au début du mélangeur doit être

jeté. Cela peut par exemple se faire dans la boîte vide.

4Introduiredelamoussecoupe-feudansl'ouverture. Au bout de 30 secondes environ (à 23°C), les com-

posants réagissent et commencent à mousser. Obturer complètement l'ouverture avec de la mousse

coupe-feu (par ex. interstices entre les câbles, etc.).

–REMARQUE–

Commencer généralement par le milieu de l'ouverture et remplir de mousse de bas en haut. Dans le

cas d'une ouverture non traversante, remplir de mousse de l'arrière vers l'avant. Après une interruption

de travail (>1 minute à 23°C ; >20 secondes à 35°C), la mousse durcit dans le mélangeur – Le mélan-

geurdoitalorsêtreremplacé.Décharger le pistolet applicateur avant de changer de mélangeur. Pour

en

de

fr

it

nl

es

pt

el

da

no

sv

pl

cs

sk

hu

hr

sl

bg

ro

li

lv

et

ru

tr

Printed: 03.12.2018 | Doc-Nr: PUB / 5167834 / 000 / 07