AQ250 SERIES HYDRONIC CONTROL PANELS

368-0306—07

1 INSTALLATION PREPARATION

NOTES: Throughout these instructions, the following

terminology conventions are used:

— AQ150 refers to the AQ15000B Control Module;

— AQ155 refers to the AQ15540B Zoning Module.

— AQ157 refers to the AQ15740B Zoning Module.

— AQ250 is used when the information applies to

both the AQ25042B and AQ25044B Control Pan-

els. Where there are specific instructions or details

relating to the “-42B” or “-44B” Control Panels, the

full model number (i.e. AQ25044B) is used;

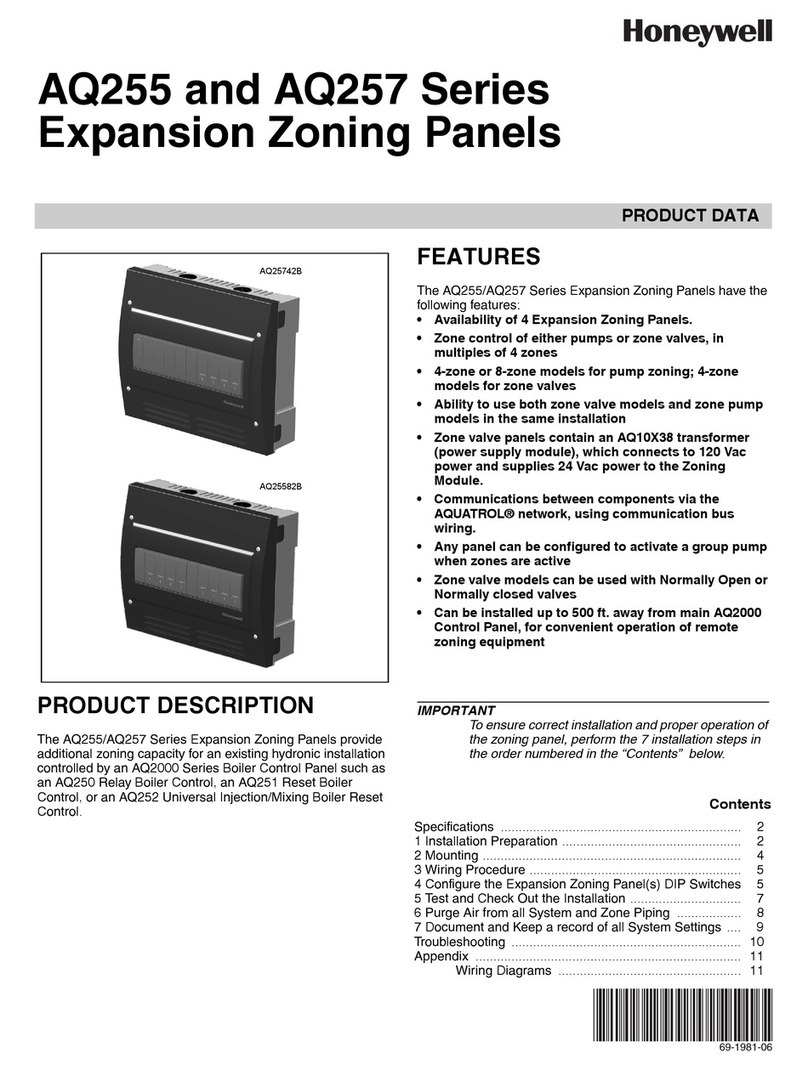

— AQ255 refers to all of the AQ25542B, AQ25582B

and AQ25742B Expansion Zoning Panels

— AQ257 refers to the AQ25744B Expansion Zoning

Panel. Where there are specific instructions or

details relating to the “-42B”, “-82B”, “-42B”, or “-

44B” Expansion Zoning Panels, the full model

number (i.e. AQ25744B) is used;

— Control Module refers to the component within an

AQ2000 Series Control Panel that performs the

master control operations. See Table 1 on page 2

for specific models.

— Control Panel refers to an assembled product, con-

sisting of a transformer, Control Module and Zon-

ing Module, all contained within an AQ2000 panel

enclosure;

— Expansion Zoning Panel refers to an assembled

product, consisting of a Zoning Module and, if

applicable, a transformer, contained within an

AQ2000 panel enclosure. Zoning Modules are

available in either 4-zone or 8-zone configurations.

Refer to literature Form No. 69-1981 for more

information on these products.

— Zoning Module refers to the component within an

AQ2000 Series Control Panel or Zoning Expansion

Panel.

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

the application.

3. Installers must be trained, experienced, and licensed

service technicians.

4. Follow local codes for installation and application.

5. After installation is complete, check out the product

operation as printed in these instructions.

Risk of electrical shock.

Can cause severe injury, property damage or

death.

Disconnect power supply before installation and

before servicing.

Check That You Have All the

Necessary Equipment For a

Successful Installation

• AQ2000 Series components:

— AQ250 Control Panel

— AQ Expansion Zoning Panels (if more than four

space heating zones in the system)

— Digital thermostats (one for every space heating

zone being controlled)

• Boiler supply and return temperature sensors (included

with the AQ250 Control Panel)

• Low voltage thermostat wire

• Zoning equipment (zone valves or pumps)

Read All Instructions Carefully

Before Proceeding

The AQ250 Control Panels are a part of a totally new series

of hydronic controls. And although they - and other

AQ2000 system components - are very easy to install and

operate, they are different than other hydronic controls

that you have previously installed. So take a moment to

read through this quick installation guide before

beginning the installation. Failure to follow them could

damage the product or cause a hazardous condition.

Familiarize Yourself With the

AQ250 Control Panel Layout

Refer to Fig. 1 on page 4. All AQ250 Control Panels consist

of three functional components:

1. AQ10X38 transformer (power supply module), which

connects to 120 Vac power and supplies 24 Vac

power to the Control Module and Zoning Modules

2. AQ15000B boiler / DHW Control Module, which

controls the boiler and domestic hot water (DHW)

functions as well as coordinating the overall opera-

tion of the hydronic system.

3. One of two different 4-zone Zoning Modules:

• AQ15740B (part of the AQ25044B Control

Panel) for zoning with 24 Vac zone valves with

end switches.

• AQ15540B (part of the AQ25042B Control

Panel) for zoning with either line voltage

circulators or 24 Vac zone valves without end

switches.

AQ250 Control Panels can control a maximum of 16 zones

by connecting additional Expansion Zoning Panels to the

AQ250 Control Panel. Each Expansion Zoning Panel is

configured with its own bank of DIP switches, located in

the left-most section of each Zoning Module. To expand

the capacity of an AQ250 Control Panel beyond 16 zones,

an AQ254 Add-A-Temperature Expansion Control Panel is

required. The hydronic system can be expanded by 16

zones for each AQ254 connected to the AQ2000 network.

A maximum of three (3) AQ254 Panels may be connected

to an existing AQ2000 Control Panel for a maximum of 64

zones connected on the AQUATROL® network

NOTE: If an AQ254 Add-A-Temperature Expansion Con-

trol Panel is used for controlling the temperature

in a mixed loop, it can reset the mixed loop tem-