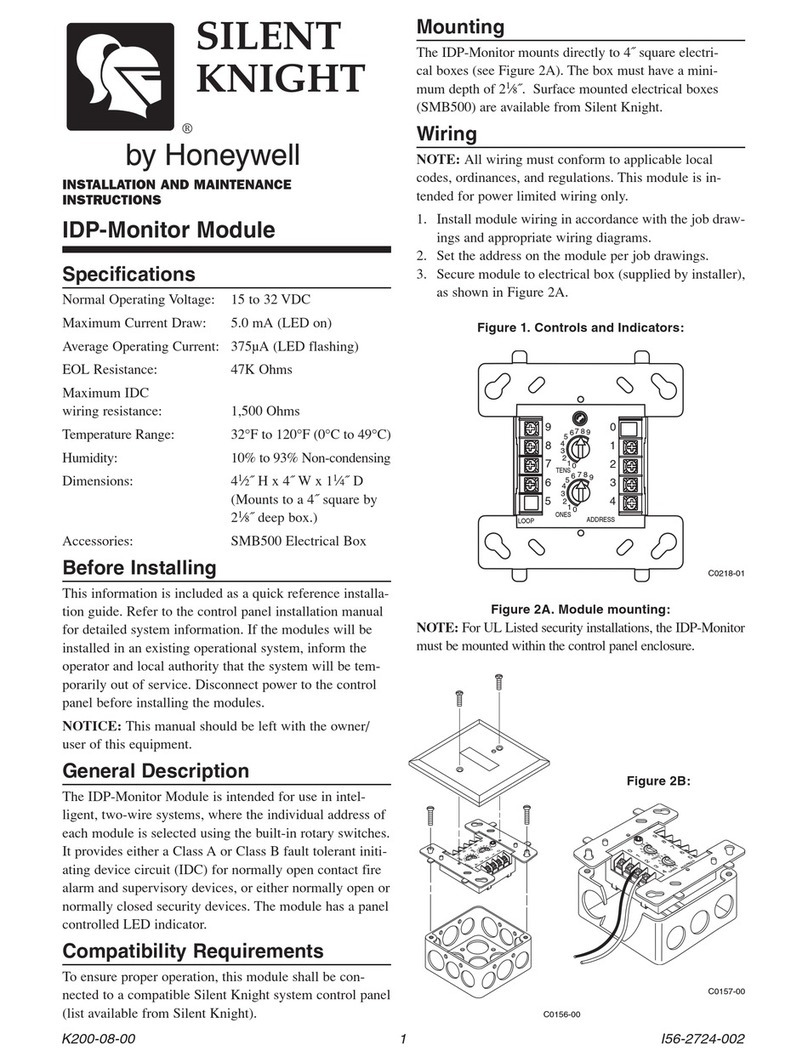

EN1R--9170 0109R1--NE3

INSTALLATION

IMPORTANT

Take care that installer is a trained experienced ser-

vice person.

Turn off gas supply before starting installation.

Disconnect power supply to prevent electrical shock

and/or equipment damage.

Do not remove seals over inlet and outlet until the

device is ready to be installed.

If M5 air pressure connection is not to be used, it is

recommanded to push a dust cap into the hole

(order nr. 45.900.426--001).

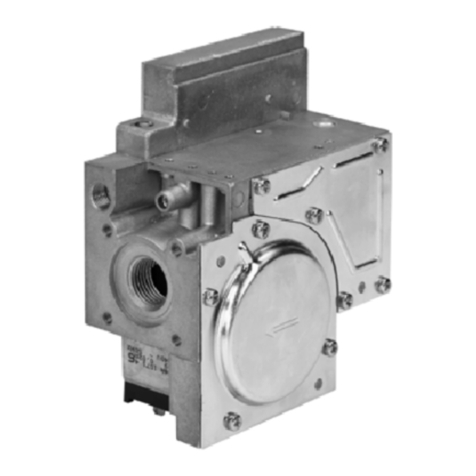

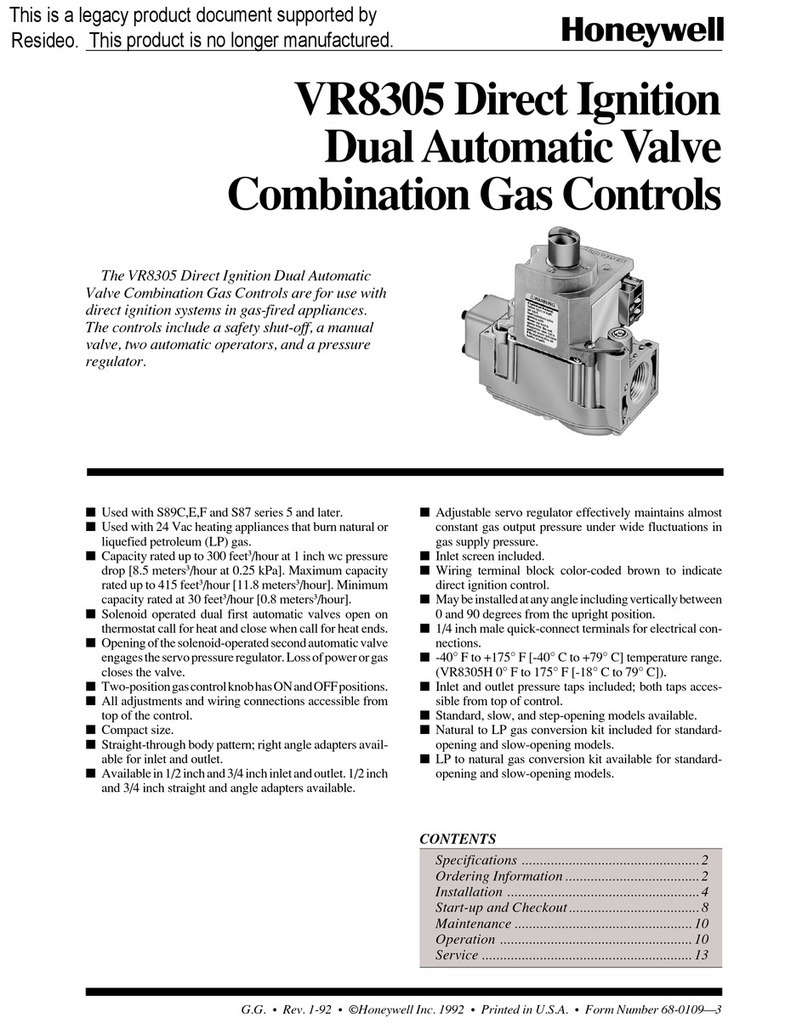

Mounting position

The gas control can be mounted 0 to 90_in any direction from

the upright position, i.e. from the position when electric

operators are on top.

Main gas connection

·Take care that dirt cannot enter the gas control during

handling.

·Use a clean taper fitting with thread according to ISO 7--1

or a piece of new, properly reamed pipe, free from swarf.

·Do not tighten the pipe or pipe fitting too far (see table

below). Otherwise valve distortion and malfunction could

result.

Pipe size Max. length of pipe thread

1/2”18.6 mm

·Apply a moderate amount of good quality thread

compound to the pipe or fitting only, leaving the two end

threads bare. PTFE tape may be used as an alternative.

·Ensure that gas flows in the same direction as the arrow

on the bottom of the gas control.

Electrical connection

CAUTION

Switch off power supply before making electrical con-

nections.

Take care that wiring is in accordance with applicable

codes and local regulations.

Ensure that cut--off function of limit control de--en-

ergizes both valves.

Use lead wire which can withstand 105 _C ambient.

Use lead wire which is proven against moisture.

The electric on/off operator is provided with:

6.3 mm quick connect terminals suitable for 6.3 mm

receptacles (e.g. ”Series 250” AMP fasteners) and special

plugs.

The electric servo on/off operator/regulator is provided with:

quick connect terminals suitable for a female connector

according to DIN 43650 and special plugs.

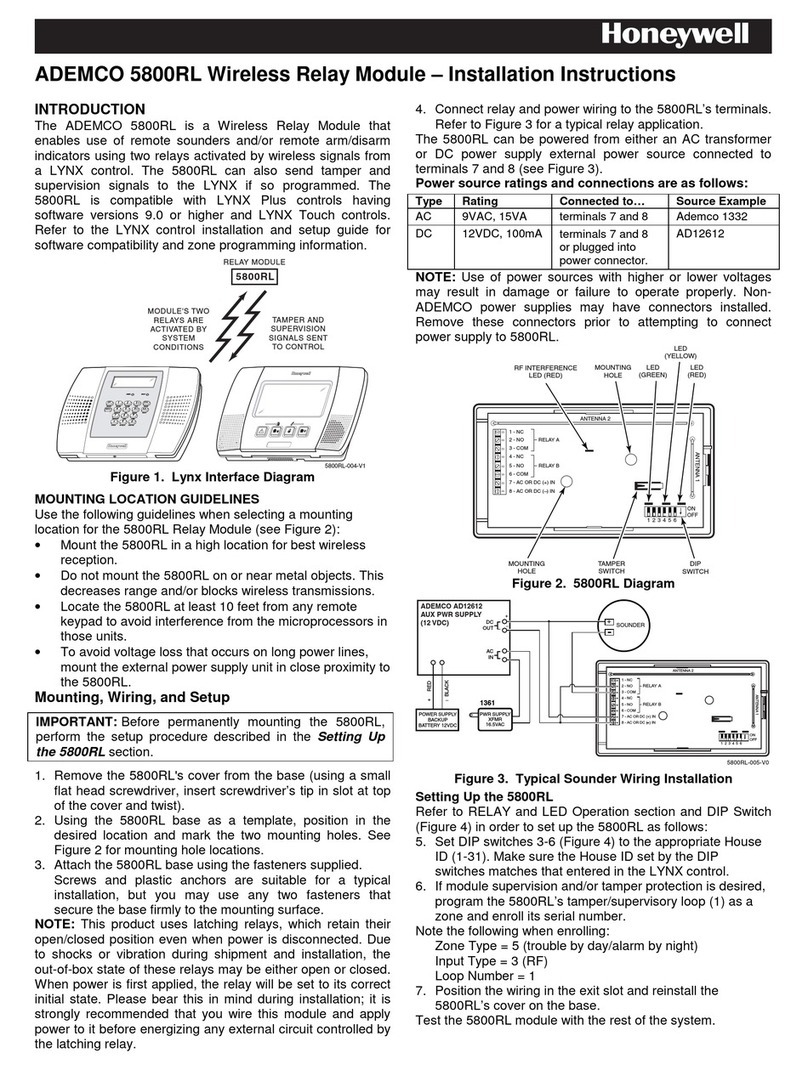

Wiring gas control in intermittent ignition (IP) system

The appliance manufacturer’s instructions should always be

followed.

Perform gas leak test

WARNING

FIRE OR EXPLOSION HAZARD CAN CAUSE

PROPERTY DAMAGE, SEVERE INJURY OR

DEADTH

Check for gas leaks with a rich soap and water solu-

tion any time work is done on a gas control.

Gas leak test

·Paint all pipe connections upstream of the gas control with

with a rich soap and water solution. Bubbles indicate a gas

leak.

·If a gas leak is detected, tighten the pipe connection.

·Stand clear while lighting the main burner to prevent injury

caused from hidden gas leaks, which could cause flasback

in the appliance vestibule. Light the main burner.

·With the main burner in operation, paint all pipe joints

(including adapters) and gas control inlet and outlet with

with a rich soap and water solution or an approved leak

detection fluid.

·If another gas leak is detected, tighten adapter screws,

joints and pipe connections.

·Replace the part if gas leak can not be stopped.

CAUTION

Keep soap and water solution away from electrical

connections.

ADJUSTMENTS

WARNING

Adjustments must be made by qualified persons only.

If the appliance manufacturer supplies checkout and/

or service and maintenance instructions carefully fol-

low them.

If such instructions are not provided then use the pro-

cedure outlined below.

Adjustment can only be made with a special tool.

Pressure tap

The gas control is provided with a pressure tap of 9 mm O.D.

at inlet and outlet side.

When checking the pressure undo the screw a half turn and

slip tube over nipple.

Ensure that screw is retightened after making test.

CAUTION

To ensure a safe closing of the valves, it is essential

that voltage over the terminals of electric operators is

reduced to 0 Volt.

Offset adjustment throttle valve versions on modulating applications

(see fig. 1.)

·Remove cap screw with a screw driver to expose offset

adjustment screw.

·Check gas supply pressure to the appliance using a

pressure gauge connected to the inlet pressure tap.

·Start fan and check air flow.

·Energize both electric operators in order to have gas input

to burner and ignite boiler.