2

of 65°C [150°F] or higher. Protect hoses and cylinders

from weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury. If

oil is injected under the skin, see a doctor immediately.

WARNING: Only use hydraulic cylinders in a

coupled system. Never use a cylinder with

unconnected couplers. If the cylinder

becomes extremely overloaded, components can fail

catastrophically causing severe personal injury.

WARNING: BE SURE SETUP IS STABLE

BEFORE LIFTING LOAD. Cylinders should

be placed on a flat surface that can support

the load. Where applicable, use a cylinder

base for added stability. Do not weld or otherwise

modify the cylinder to attach a base or other support.

Avoid situations where loads are not

directly centered on the cylinder plunger.

Off-center loads produce considerable

strain on cylinders and plungers. In addition, the load

may slip or fall, causing potentially dangerous results.

Distribute the load evenly across the entire

saddle surface. Always use a saddle to

protect the plunger.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized ENERPAC Service Center in your

area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or

damaged parts by genuine ENERPAC parts.

Standard grade parts will break causing

personal injury and property damage.

ENERPAC parts are designed to fit properly and

withstand high loads.

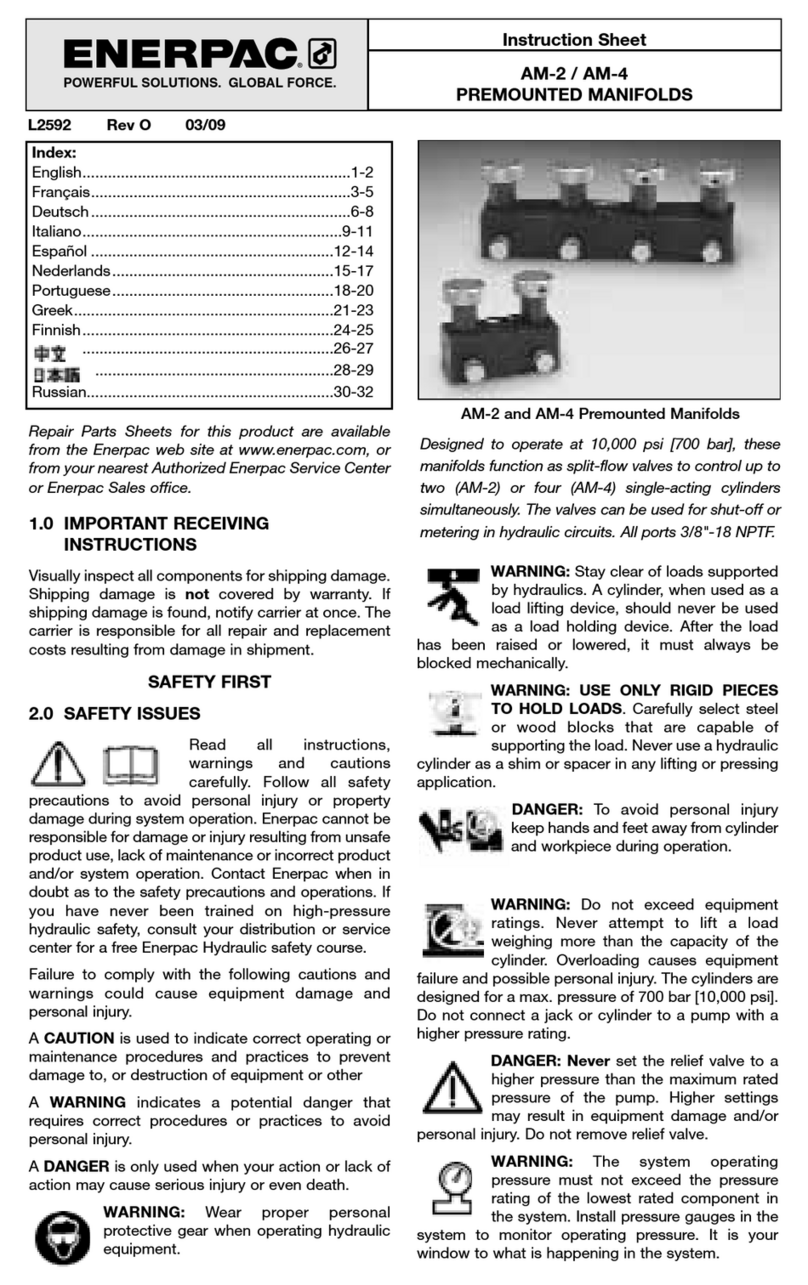

3.0 HYDRAULIC CONNECTIONS

3.1 Check All Coupler Connections

1. Use Enerpac hi-flow couplers for best results,

or Enerpac regular couplers when very low flow

pumps are used. (Maximum flow below 1 GPM

— 230 cu. in./min.)

2. Connect hoses to valve at designated port

locations. If using pipe sealants on male pipe

threads, use sparingly and never over ends of

fittings where it can be torn loose and get into

system.

4.0 OPERATION

1. Connect and secure hoses and cylinders noting

that the proper ports are connected.

2. Quick disconnects must be fully engaged and

locking collars drawn up fully to ensure free flow

of oil between valve and attached component.

3. Before starting pump rotate valve handle counter-

clockwise (CCW), viewed from the top, to open

the valve to tank line. Pump can now be run but

pressure will not build.

4. To build pressure, rotate the handle clockwise

(CW) until the handle stops closing the valve.

Pump can now build pressure. Rotation (CCW

)will release the pressure and/or load and the

decent is controlled by the amount of rotation.

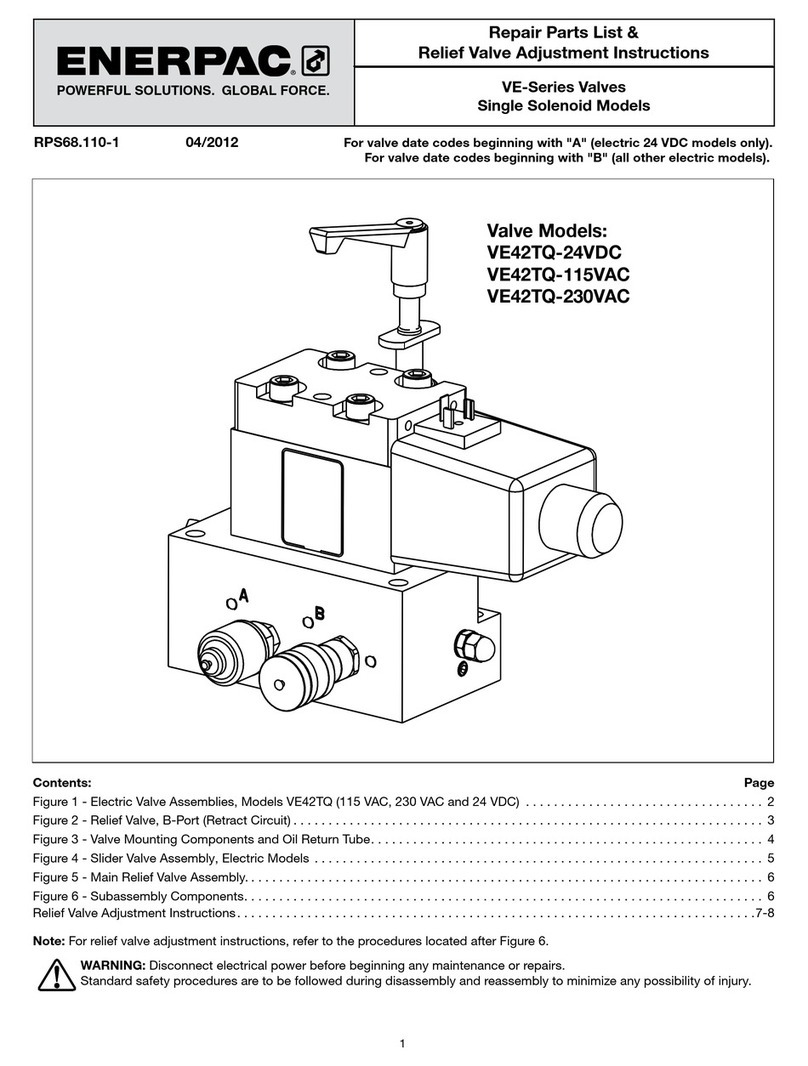

NOTE: The VM22 and VM32 Enerpac valves are

equipped with an integral user adjustable relief

valve. This relief valve is factory set to 10,000

psi [700 bar]. The valve can be adjusted by first

loosening the jam nut and either rotating the

setscrew clockwise to increase system pressure

or counter-clockwise to reduce system pressure.

Set screw must be locked in place with the jam

nut when adjustments are done.

5.0 TROUBLE SHOOTING

1. System will not build pressure. Check relief valve in

the control valve or in the pump, for proper setting

(see pump repair sheet or valve repair sheet).

Check and secure all hose connections. If trouble

is not corrected, remove cylinder and hoses from

the valve. Now place a pressure gauge in port A

and close (CW) the valve. If pressure cannot be

developed, the unit should be taken to the nearest

authorized ENERPAC Service Center. If pressure

develops, the cylinder, hoses or couplers are the

problem.

2. The cylinder will not build pressure. This is an

indication of a worn valve seat which must be

replaced by a Service Center.

3. VM22 has a check valve in-line with the pressure

port. This check will hold the pressure at port A

after the pump is turned off. When the pump is

functioning properly, the valve closed, you can jog

the pump and hold the pressure at port A.

6.0 MAINTENANCE

1. Periodically check all hydraulic connections to be

sure they are tight. Loose or leaking connections

may cause erratic and/or total loss of operation.

Replace or repair all defective parts promptly.

2. Periodically check the hydraulic oil level in your

system.

3. Change hydraulic oil approximately every 250-300

hours of operation. In dusty or dirty areas, it may

be necessary to change the oil more frequently.

7.0 STORAGE INSTRUCTIONS

In the event that the unit would be stored for any great

length of time (30 days or more), prepare as follows:

1. Wipe the entire unit clean.

2. Disconnect all hydraulic lines to prevent accidental

operation.

3. Cover the unit with some type of protective

cover.

4. Store in a clean, dry environment that is NOT

exposed to extreme temperatures.