7

Type 63EGLP/63EGLP-16

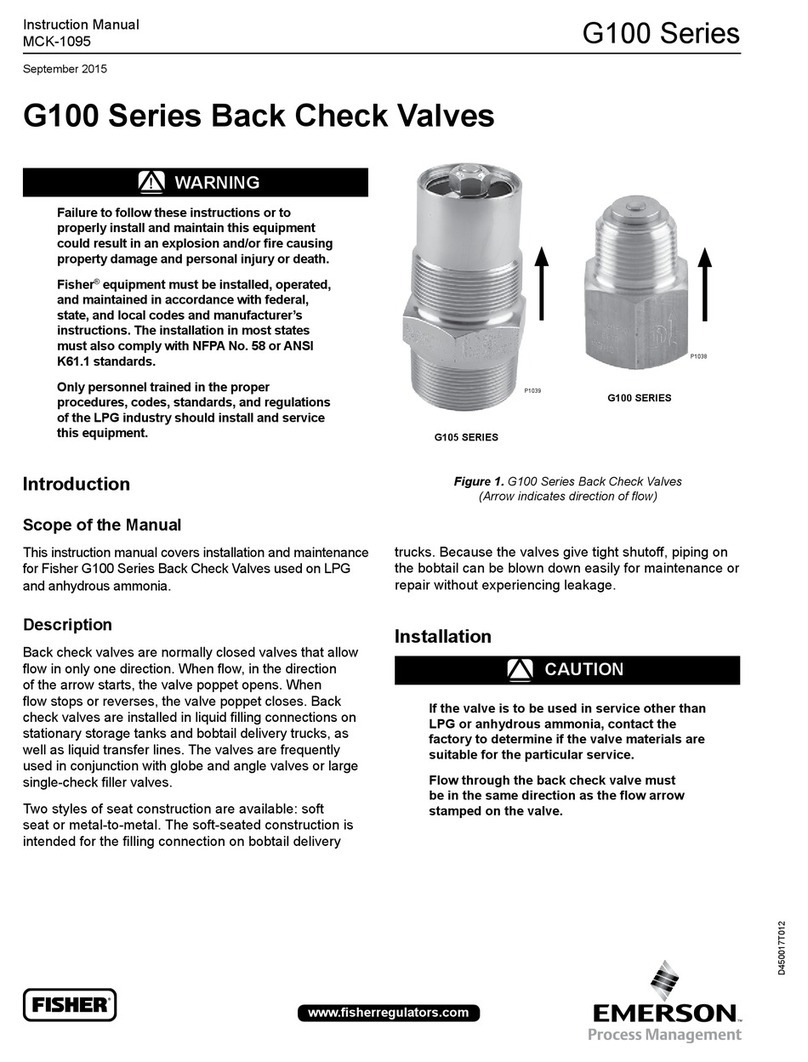

2. For Type 63EGLP: Use the lifting sling (key 50)

wrapped around outlet flange (as shipped) to lift the

Type 63EGLP when installing the unit. After installing

the valve on the tank, install rain cap (key 51)

on outlet flange. Ensure that the valve is in the

vertical-up orientation with flow through it matching

the direction of the arrow on the main valve body. An

upstream control line is not required because of the

integral pilot supply tubing.

For 63EGLP-16: Carefully lift the Type 63EGLP-16,

avoid lifting by the pilot assembly. After installing

the valve on the tank, ensure the valve is in the

vertical-up orientation with flow through it matching

the direction of the arrow on the main valve body.

Exercise care to ensure that the hex nipple (key 48)

at the valve body is not cross threaded with tank

coupling. An upstream control line is not required

because of the integral pilot supply tubing.

▲ WARNING

Type 63EGLP/63EGLP-16 Relief Valves

vent gas from the main valve outlet and

from the pilot exhaust. In hazardous or

ammable gas service, personal injury,

death or property damage may occur

due to re or explosion of accumulated

vented gas.

To prevent such injury or damage, vent the

gas to a safe location. Design and install

exhaust piping to guard against excessive

ow restriction. Protect the pilot vent and

exhaust piping from condensation or

debris that can clog it.

3. If system operation is necessary during maintenance

or inspection, one pilot valve can be isolated while

the other pilot valve actively loads the main valve

body to continuously protect the system. If service

to the main valve body is required, remove the

upstream pressure.

4. Install a relief valve so that the pilot will exhaust

properly and into a safe place. The pilot spring case

vent must be kept open to atmospheric pressure.

Protect this vent from icing, moisture or other

blockage as required. If the vent assembly (key 16)

remains in the pilot exhaust port (connection A,

Figure 5), it must be pointed down if possible or

otherwise protected.

5. If the exhaust is to be piped to the main valve outlet

or remotely vented, remove the vent assembly

and install obstruction-free tubing or piping with a

minimum number of bends into the 1/4 NPT pilot

exhaust connection. Provide protection on a remote

vent by installing a screened vent cap into the remote

end of the vent pipe.

6. If using pipe, apply a good grade of pipe compound

to the male pipe threads before making the

connection. Install tubing or piping into the

appropriate pilot connection.

7. The set pressure of a unit is adjusted by changing the

control spring compression on the pilot valve.

8. The pilot valve is factory-set for the pressure set-point

specified on the order. Some certifications require the

adjusting assembly be protected from tampering and

will come factory-installed with a tamper-evident wire

seal. These units are not adjustable.

Dual Pilot-Valve Active Monitoring

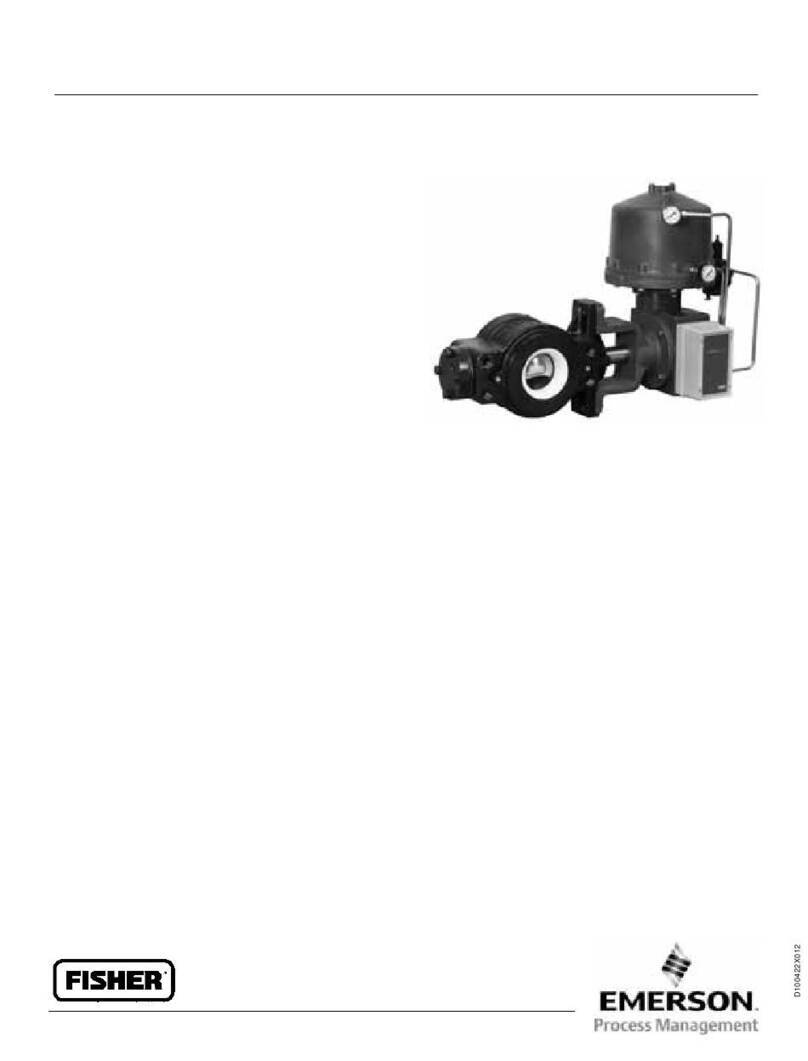

The Type 63EGLP/63EGLP-16 Pressure Relief Valve

with dual-pilot assembly is shipped from the factory with

the handle assembly, (key 48), pointing to one pilot valve,

or the other. In this operating mode, it has an active

pilot and a standby pilot. Only the active pilot senses the

changes in the inlet pressure. The handle assembly is

always pointing away from the active pilot.

The Type 63EGLP/63EGLP-16 Bulk Storage Relief Valve

can be adjusted for use with BOTH pilot valves active,

by placing the 3-way ball valve selector handle (key 48)

in the middle position. When the 3-way selector valve

handle is in the middle position, then both pilot valves are

in an active mode to sense tank (upstream) pressure and

will operate normally for start-to-discharge and reseal of

the main valve.

While operating in this mode with the 3-way selector

valve handle in the middle position, even if one pilot

valve’s exhaust discharge port is blocked and unable

to discharge loading pressure, the alternate pilot will

continue to actively sense upstream (tank) pressure and

begin to discharge loading pressure per its set-point.

This allows the main valve body to begin to relieve tank

pressure at the alternate pilot valve’s set-point.

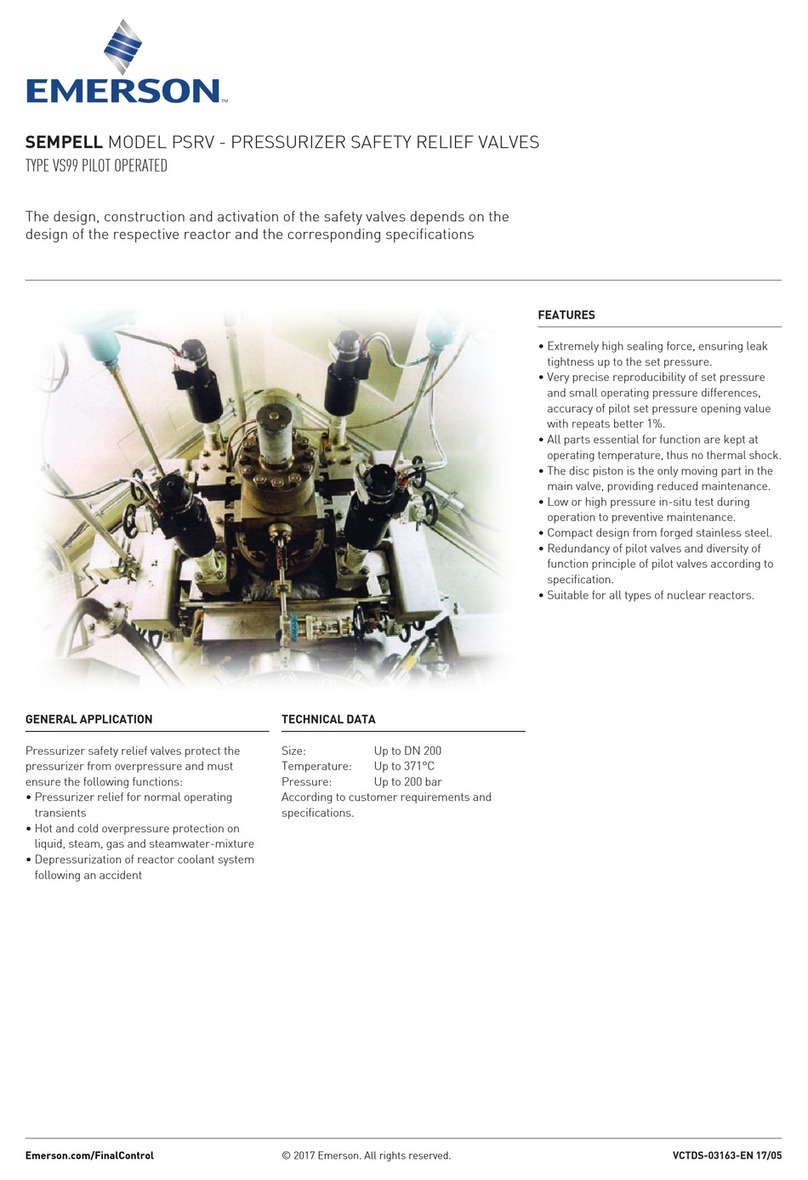

The attached figure represents the pilot valve assembly

and 3-way selector ball valve handle in the above

described middle position.

To check for proper positioning and orientation of the

3-way selector valve in the middle position, see Figures

7, 8 and 9 for the location of the “T” symbol on the small

valve stem of both 3-way ball valves. The small “T”

symbol on the ball valve stems must indicate the same

direction and flow path to all 3 valve ports on a given

3-way valve, while the handle assembly (key 48) is in the

middle position.