L7224U OIL AND ELECTRIC BOILER ELECTRONIC AQUASTAT®CONTROLLER

3 69-1720EFS—07

New Installation

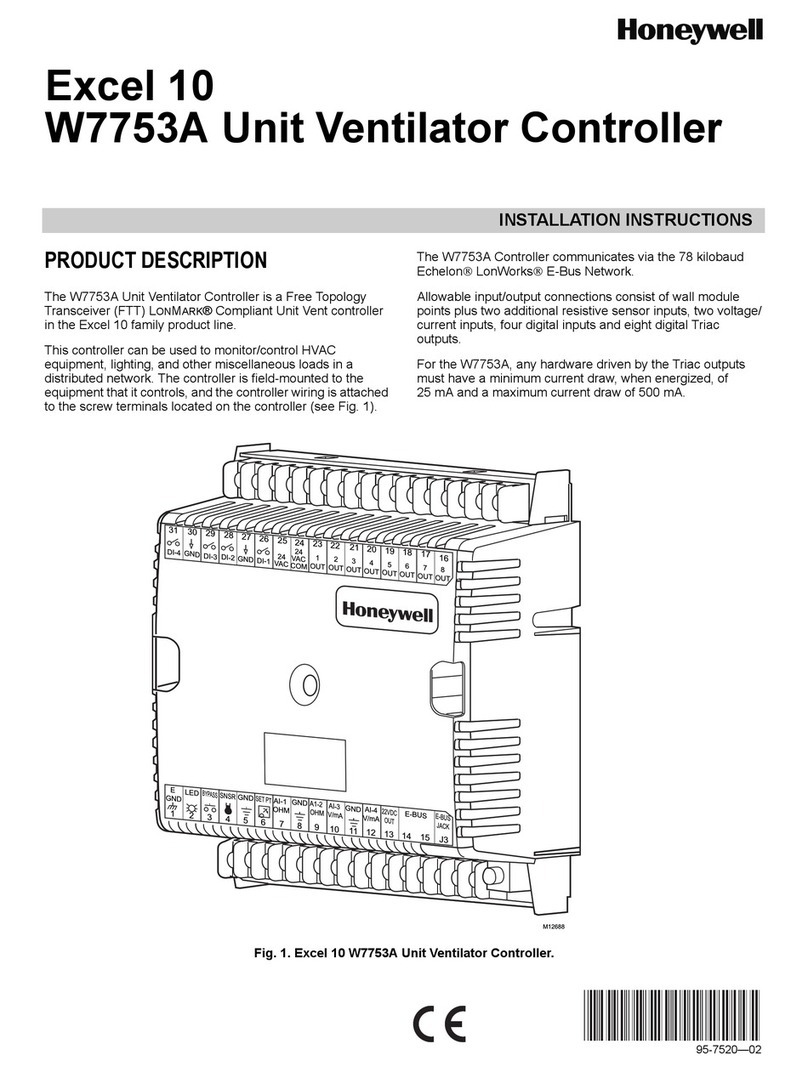

Order well assemblies separately; refer to Table 1 and

form no. 68-0040, Immersion Wells and Compression

Fittings for Temperature Controllers. Boilers usually have

tappings that allow the well to be mounted horizontally so

boiler water of average temperature can circulate freely

over the well. See Fig. 1 for mounting dimensions.

1. Turn off all power and drain the boiler, if applicable.

2. If no tapping is provided, prepare properly sized and

threaded tapping near the top of the boiler.

3. Sparingly coat the well threads with pipe dope.

NOTE: Do not attempt to tighten by using the case

as a handle.

4. Install the well in the boiler tapping and tighten

securely.

5. Refill boiler and check for water leakage.

6. Identify if installation requires vertical or horizontal

mounting.

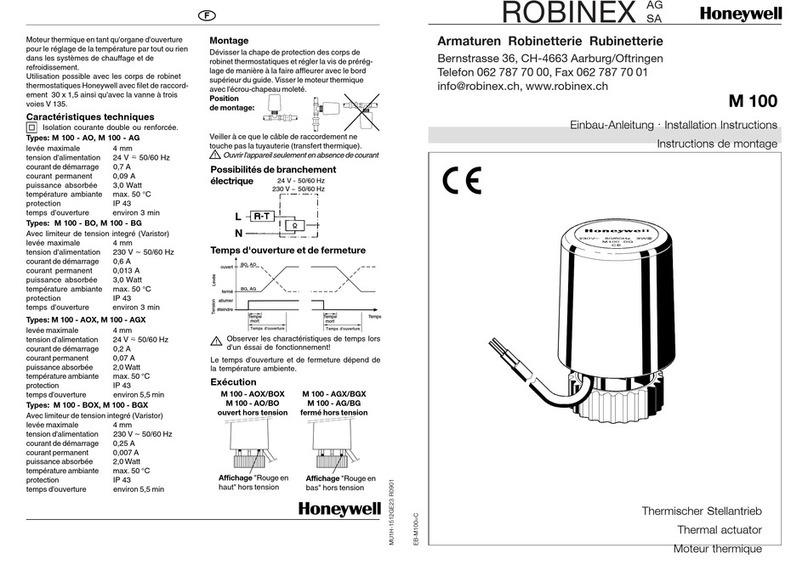

7. Remove the well knockout, for either vertical or

horizontal mounting, by carefully prying the

knockout from the back of the case, using a

flat-bladed screw driver. Refer to Fig. 2.

8. Loosen but do not remove the well clamp screw.

9. Fit the case into the well so the clamp on the case

slides over the flange on the well.

10. Securely tighten the clamp screw.

11. Insert the sensor element into the well until it

bottoms. (If necessary, slightly bend the wire inside

the case to hold the sensor against the bottom of

the well.)

12. Turn power ON.

13. Set High Limit, Low Limit and Differentials to the

settings recommended by the boiler OEM. (See

OPERATION section, also refer to INSTALLATION

steps 6 and 7.)

Fig. 2.

Removing horizontal or vertical mounting

knockout.

IMPORTANT

Best thermal response is obtained with a well

that snugly fits the sensor. Insert the sensor until

it rests against the bottom of the well. Use a well

of correct length and bend the wiring, if neces-

sary, to hold the bulb against the bottom of the

well.

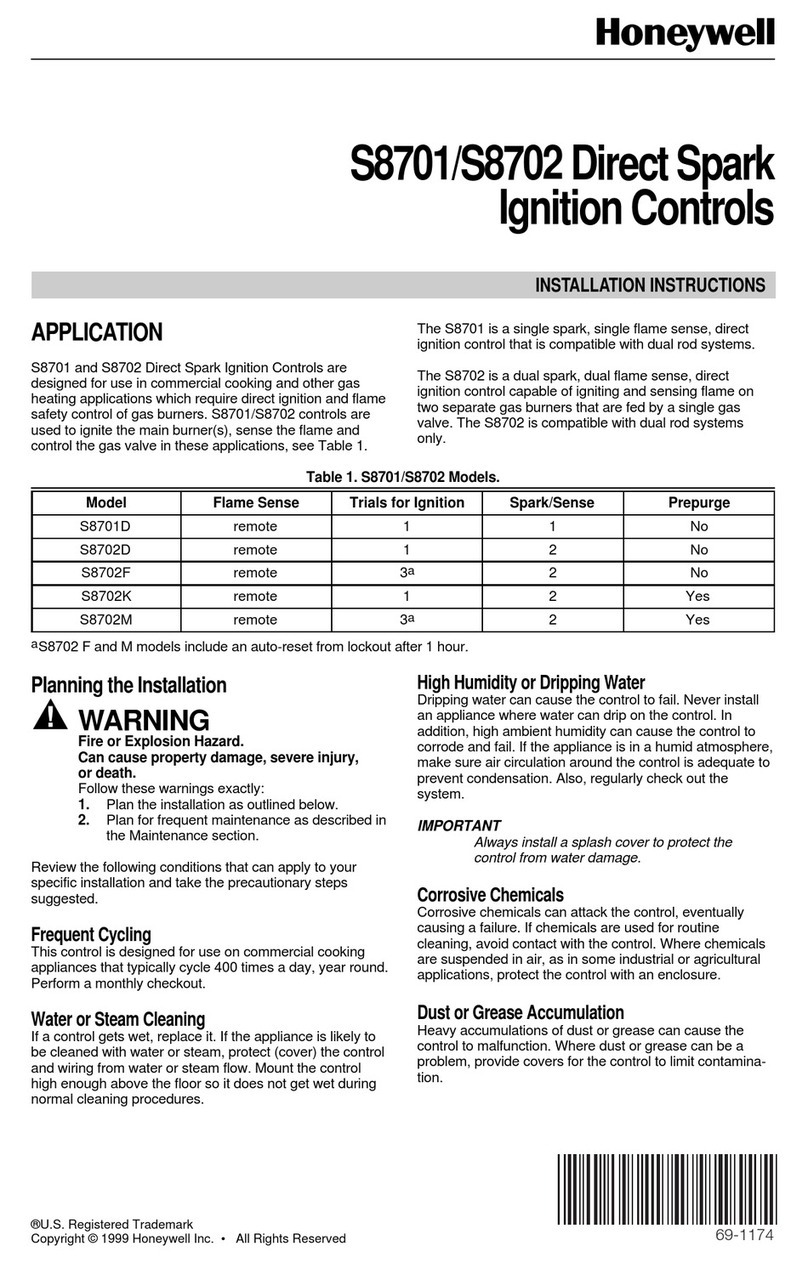

If the well is not a snug fit on the sensor, use the

heat-conductive compound (furnished with

TRADELINE®models) as follows: Fold the

plastic bag of compound lengthwise and twist it

gently. Then snip off end of bag and work the

open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly

to distribute compound evenly in the well. Bend

the wiring, if necessary, to hold the sensor

against the bottom of the well and to hold outer

end of the sensor in firm contact with the side of

the well. See Fig. 3. Wipe excess compound

from the outer end of the well.

Fig. 3. Position of sensor in immersion well.

Flush-Mounted Aquastat

Replacement

Turn off all power and remove the old controller. Refer to

the cover insert of the old controller to identify and tag

each external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and replace it

with a suitable new well. If the old well is suitable, use it.

See Fig. 1 and 4 for mounting tab location.