SUPER TRADELINE L4064B

Universal Combination Fan and Limit Controllers

APPLICATION

The L4064B controls the on and off operation of the

heating unit’s fan motor and provides high limit control

of the main burner. It is suitable for all types of forced

air heating systems.

The L4064B’s bimetal sensing element turns fan on

and off according to plenum temperature.

The L4064B has a manual switch to provide

continuous fan operation, mounting adapters for

replacing competitive devices, adapters for wiring

convenience, and a strain relief bushing for protecting

the wiring from damage due to field abuse.

Limit contacts are suitable for line voltage, low

voltage or millivoltage circuits.

The fan-on timing can vary depending on applied

voltage and switch ambient.

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to

follow them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and

on the product to make sure the product is suitable

for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Failure to remove brass jumper, if limit switch is

in low voltage circuit, can cause electrical shock

hazard or damage low voltage controls.

1. Disconnect power supply before connecting

wiring to prevent electrical shock or equipment

damage.

2. When connecting cable or conduit to control,

avoid straining the control case.

Follow furnace or burner manufacturer’s

instructions, if available. The L4064B has a

maximum switch temperature of 190OF (88OC),

maximum element temperature of 350OF (177OC).

Do not exceed these temperatures or the following

electrical ratings (amperes):

Pilot Duty: 2 A at 24 Vac; 0.25 A at 0.25 to 12 Vdc.

Maximum Combined Connected Load: 2000 VA.

75OC (167OF) (min.) field wiring required. Wiring must

conform to NEC Class 1 requirements.

!

WARNING

!

CAUTION

120 Vac 240 Vac

FAN LIMIT

LIMIT FAN

14

84

8

48

7 4

42 54

Full Load

Locked Rotor

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN, 55422

www.honeywell.com/building/components

07/06 RB

© Honeywell 2006 Printed in Canada

69-0117-3

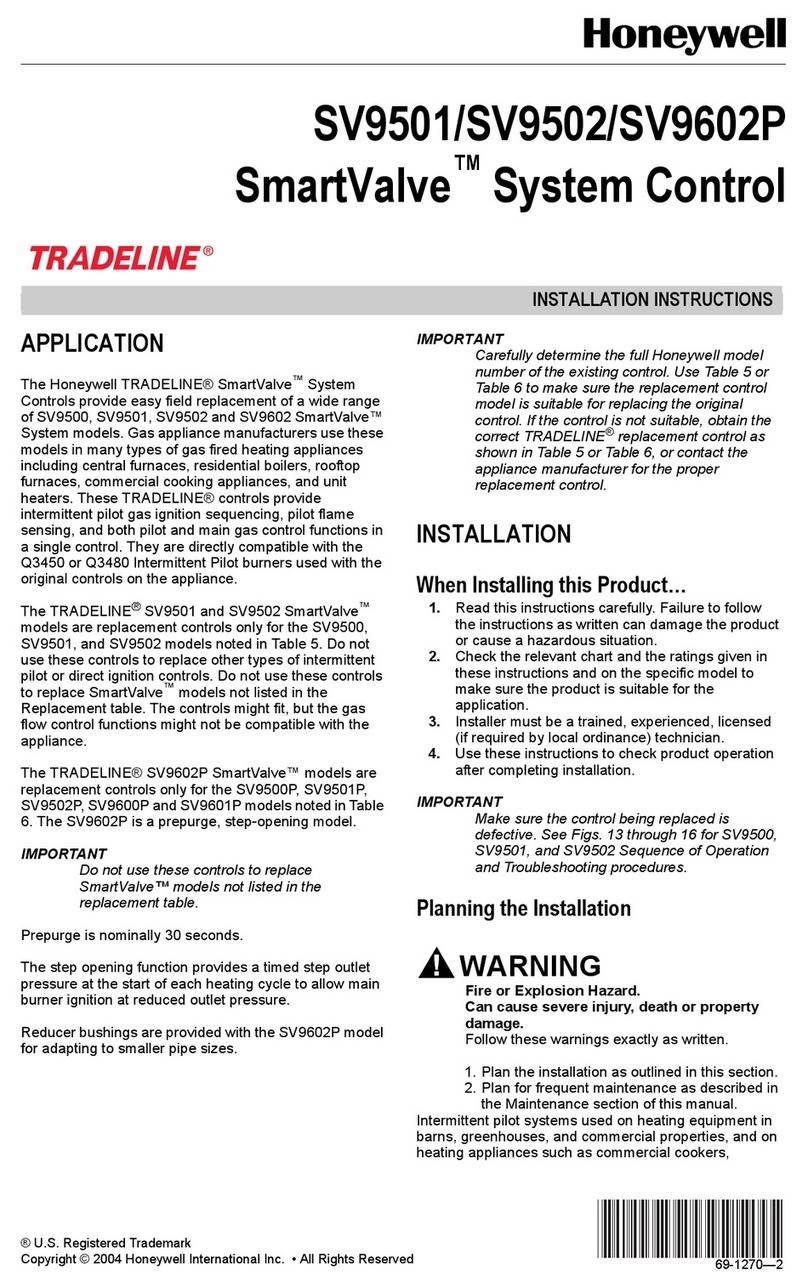

Fig. 9 - A: Limit in low voltage circuit.

B: Limit in line voltage circuit.

C: Limit in line voltage circuit without jumper.

the fan contacts (at the FAN ON temperature setting).

During normal operation, the call for heat end before

the LIMIT setting is reached, and the fan contacts break

as the plenum temperature falls and the FAN OFF

setting is reached.

If the call for heat continues until the temperature in

the plenum rises to the LIMIT setting, the bimetal

element will mechanically break the limit contacts and

de-energize the gas control circuit.

CHECKOUT

When installation is complete, disconnect the fan

motor circuit at the L4064. Turn on power and set

thermostat to call for heat. Burner should come on and

limit controller should shut burner off when plenum

temperature reaches the limit set point. Turn off power,

recconnect the fan switch, turn on power and again set

thermostat to call for heat. Fan should come on when

plenum temperature has reached fan-on setting.

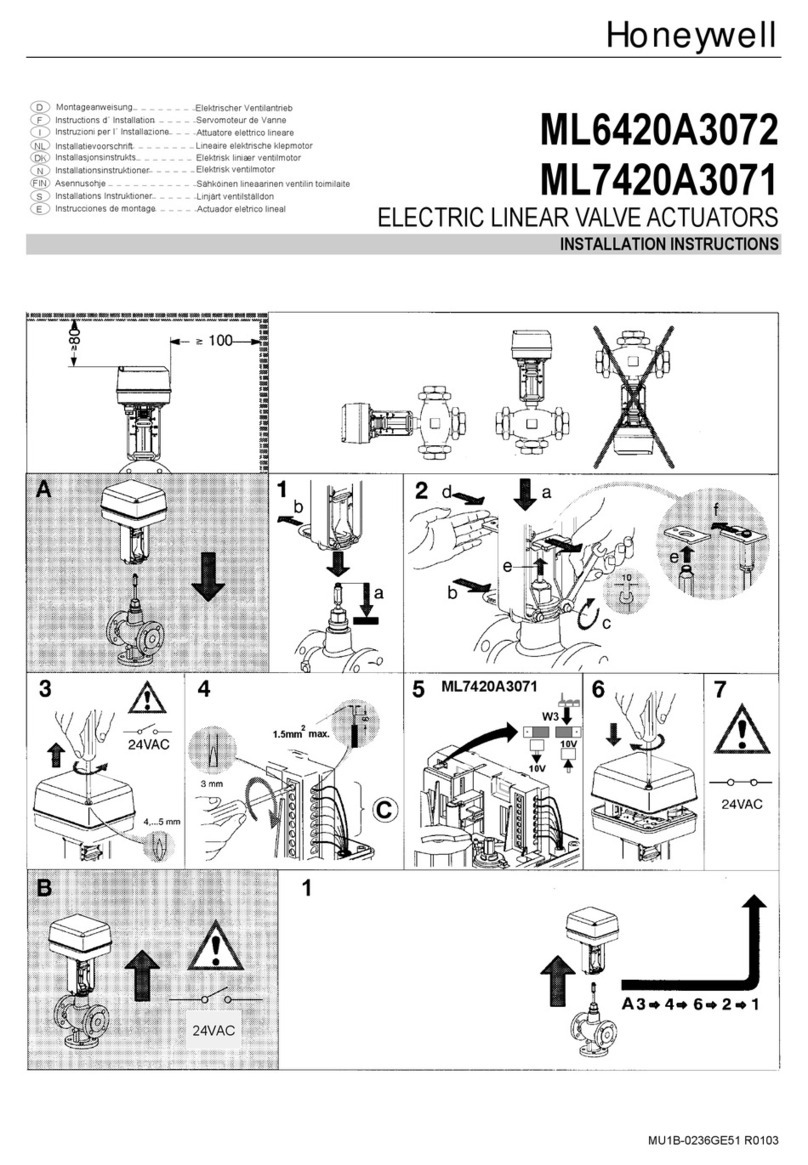

Fig. 10 - Changing the high limit stop.

SETTINGS AND ADJUSTMENTS

FAN SETTING ADJUSTMENT

1. Move the FAN OFF lever to the temperature at

which the fan is to stop to prevent circulation of cool

air.

2. L4064B - Move the FAN ON lever to the

temperature at which the fan is to come on.

MANUAL FAN SWITCH

For constant fan operation, push the FAN switch

button in. For fan to cycle automatically, pull button

out.

LIMIT SETTING ADJUSTMENT

These controllers have a limit stop which prevents

the limit indicator lever from being adjusted beyond

the equipment manufacturer’s specifications.

1. Push the small end of Limit Adjust Tool

(196722) through hole in scaleplate (located at

caution marking) to depress the stop disc not more

than 1/16 in. (1.6 mm) to release stop lock (Fig. 10).

Stop disc is on back of scaleplate.

2. While depressing the stop disc, insert the long

end of Limit Adjust Tool next to limit stop (Fig. 10)

and move the stop to desired setting.

If the L4064 is

a replacement control, high limit stop setting should

be the same as that of the control being replaced.

(Move stop clockwise to lower the setting,

counterclockwise to raise it.) Then remove the

limit stop adjust tool.

3. Set the LIMIT OFF lever to the temperature at

which the high limit switch is to open to stop the

burner. If the high limit stop has been properly set,

the LIMIT OFF lever should be as high as the stop

permits.

OPERATION

As the plenum temperature rises, the bimetal sensing

element of the control wraps and mechanically makes

When adjusting the fan and limit set point levers

(Fig. 10), hold the scalepale dial to keep it from turning

and straining the sensing element.

Move each indicator lever to the control point

recommended by the burner or furnace manufacturer.

Use gentle finger pressure.

L4064 L4064

B

AC

FAN

SIDE

FAN

SIDE

LIMIT

SIDE

LIMIT

SIDE

JUMPER

REMOVED

JUMPER IN

PLACE

POWER

SUPPLY POWER

SUPPLY

FAN

MOTOR

FAN

MOTOR

1

2

2

1

1

3

3

L1

L1

L2 L2

ADD DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED

TO CONTROL LOW VOLTAGE EQUIPMENT

TO CONTROL LINE VOLTAGE

FAN

MOTOR

FAN

SIDE

LIMIT

SIDE

L1

L2

POWER

SUPPLY

1

(HOT)

(HOT) (HOT) 120V

JUMPER

REMOVED

L4064

24V

2

HEATING SYSTEM

TRANSFORMER

11,221

PRODUCT DATA

!

CAUTION

LOCATION

If this is a replacement installation, locate the

L4064 in the same location as the control being

replaced. Sensing tube length should be same as

old control. If this is a new installation, the element

should be installed only by a trained, experienced

service technician according to the furnace

manufacturer’s instructions. The element must not

touch any internal part of the furnace.

The electrical rating is at maximum switch

temperature of 190OF (88OC). If plenum surface

temperature exceeds 190OF (88OC), heat

insulating material or a mounting bracket must be

used.

MOUNTING

The device may be mounted either on the

plenum surface or with a bracket (rigid or swivel).

SURFACE MOUNTING

Hole in plenum should be just large enough to

accommodate the 3/4 in. (19.1 mm) diameter

element tube, Fig. 1. For adequate clearance, a

13/16 in. (20.6 mm) diameter hole is

reccomended.

1. Remove cover by squeezing sides and

pulling off. Insert element in plenum and mark

location of mounting holes. Make sure the case is

snug against the plenum before marking the

mounting screws.

2. Punch or drill holes for mounting screws.

3. Place insulation between plenum and case if

necessary.

4. Fasten controller securely with mounting

screws.

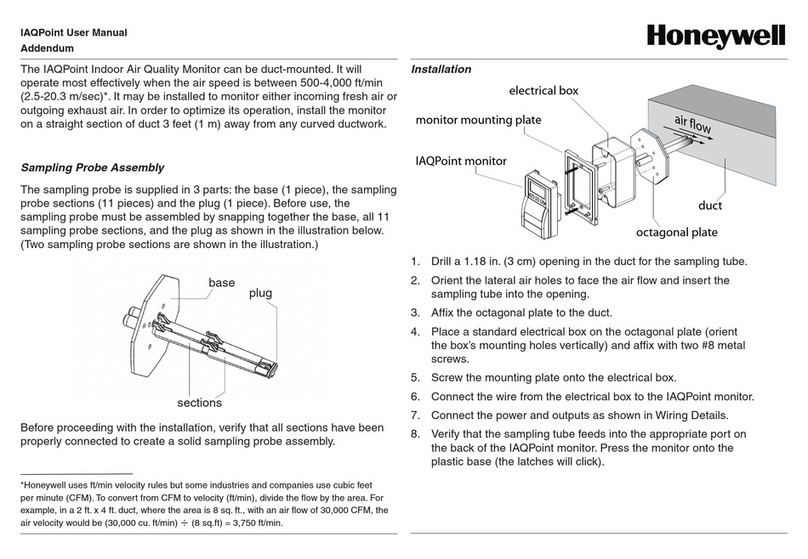

Fig. 1 - Surface mounting requires a hole 13/16

in. (20.6 mm) diameter for element insertion.

NOTE:

50

100

150

200

250

ON

FAN

OFF

FAN

OFF

DO NOT ROTATE - HOLD DIAL

WHEN SETTING POINTERS

CAUTION

1

1HOMEOWNER: THIS IS A "SAFETY STOP". DO NOT ALTER

2704E

FAN OFF SET

POINT LEVER

FAN ON SET

POINT LEVER

SCALEPLATE

TO RELEASE STOP,

PRESS STIFF WIRE

IN HOLE

ADJUSTABLE

LIMIT STOP

LIMIT SET POINT LEVER

(FACTORY-SET AT 200

O

F

(93

O

C)

LIMIT STOP

TOOL