5 60-2309—8

V4055A,B,D,E

INSTALLATION

INSTALL VALVE

The actuator is mounted directly on the valve bonnet

afterthevalveisinstalled inthegas supplyline.Refer tothe

instructions packed with the gas valve for installation de-

tails. When installing the valve, assure that:

1. Sufficient clearance is left for installation and service

of the actuator.

2. Ambient temperatures at the valve location will re-

mainwithin-40°to150°F[-40°Cto66°C]or-10°Fto158°F

[-23°C to 70°C] (see Specifications section).

3. Position of the valve permits hookup to the damper if

one is controlled.

INSTALL ACCESSORY SWITCHES (IF NEEDED)

A spdt auxiliary switch may be installed to operate a

load up to 1/2 hp [0.37 kW]. The switch may be adjusted to

operate at any point in the valve stroke.

A proof-of-closure switch may also be installed on any

V4055 actuator to provide a valve seal overtravel interlock

when used with a V5055C or E valve (with double seal).

The spdt proof-of-closure switch is installed to make or

break a circuit when the valve is in the closed position. The

switch is not adjustable.

NOTE: Mark the actuator or valve to indicate any changes

made.

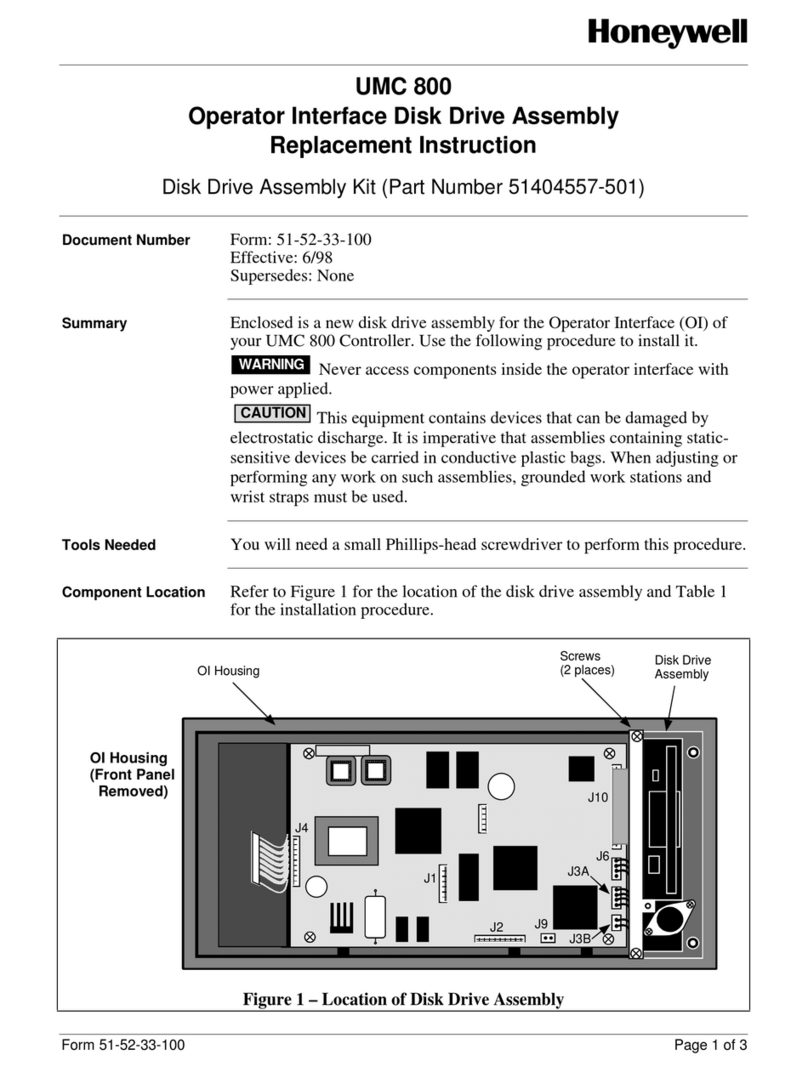

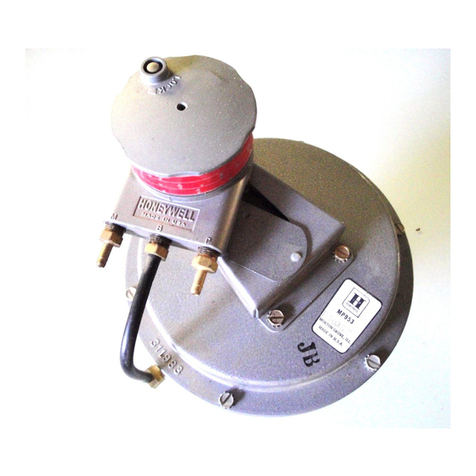

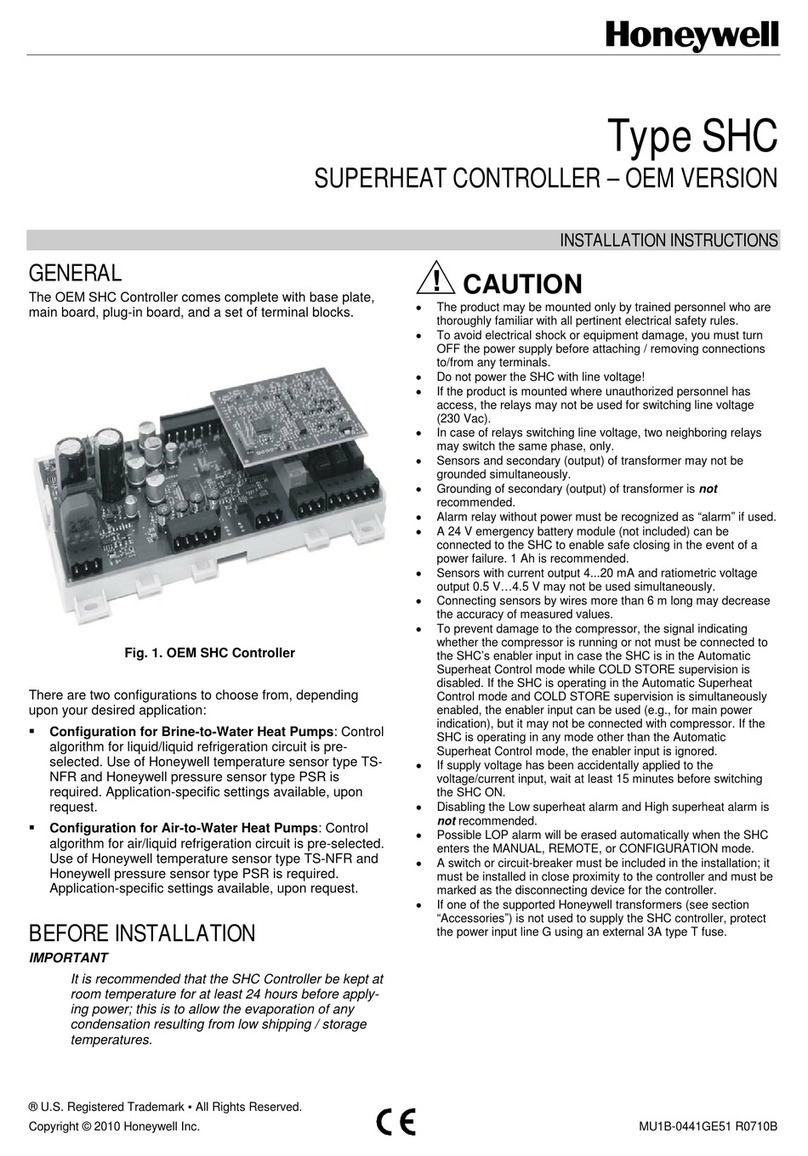

Fig. 2—V4055 Actuator with cover removed.

4. Inserttheproof-of-closureswitchinthepositionshown

in Fig. 2. The switch mounts against the side of the actuator

housing.Themounting holesare spacedto mounttheswitch

only in the correct position. Fasten with two screws through

the actuator base. The proof-of-closure switch is not adjust-

able.

5. If only one switch is used, install the narrow barrier

included with the switch in the unused space.

6. Mounttheactuator beforemakingwiring connections

and adjustments to the auxiliary switch.

MOUNT ACTUATOR ON VALVE

Checkthefinal positionof thevalve body tobe surethat

theactuator willbein theproperposition whenmounted on

thevalve.This isespeciallyimportantif theactuator isused

to drive a damper.

If two smaller sized valves are mounted very closely

together,as inan IndustrialRiskInsurers typevalvetrain, it

may be necessary to mount the actuator off center to

provide adequate clearance.

Slip the bottom collar of the actuator over the valve

bonnet assembly. Rotate the actuator to the desired posi-

tion and use a 5/32 inch Allen wrench to securely tighten

the two set screws. (50 to 60 lb/in [5.7 to 6.8 Nm]).

Connect the damper linkage, if used. Refer to the in-

structions packed with the damper arm.

TO REPLACE A V4034 ACTUATOR ON A V5034

VALVE

IMPORTANT:Whenreplacing astandard(26sec) V4034

actuator on a V5034 Valve, check the main burner

flame-establishing period (MFEP) of the burner pri-

mary safety control. If the MFEP is 10 sec, you must

use a fast-opening (13 sec) V4055 Actuator on the

older V5034 Valve.

The initial action of the V4055 Actuator does not

immediatelyopentheV5034Valvebecauseofadiffer-

ence in stroke length. The pilot may be shut off before

themainburnerflameisestablished.Thefast-opening

V4055ActuatorwillopentheV5034Valvefastenough

to establish the main burner flame within the ten

second flame-establishing period.

If it is desirable to maintain the slower opening

characteristic of the standard V4034 Actuator, both

the V4034 Actuator and V5034 Valve should be re-

placed. Use a standard V4055 Actuator on a V5055

Valve.

Select the correct adapter, depending on whether the

V5034 has a long or short stem (Fig. 3). Fasten the adapter

to the V5034 Valve bonnet, and then mount the actuator on

theadapter. Followtheinstructions formounting theactua-

tor on the valve.

If the V4034 being replaced is equipped with a heater,

therewill bealow limitcontrol connectedinseries withthe

V4034 power supply to prevent actuator operation below

25°F [-4°C]. There will also be a constant source of the line

voltage power to the heater and its control thermostat.

133568

AUXILIARY

SWITCH

133569

PROOF-OF-

CLOSURE

SWITCH

EACH SWITCH

SECURED BY TWO

SCREWS FROM

BOTTOM OF BASE.

ADJUSTING

SCREW FOR

AUXILIARY

SWITCH

IF ONLY ONE SWITCH IS

USED, INSTALL BARRIER

IN OPEN POSITION.

M7326

To install the switches, proceed as follows:

1. Remove the actuator faceplate (two screws).

2. Removethesliver-coloredbarriertoexposetheactua-

tor stem.

3. Insert the auxiliary switch in the position indicated in

Fig. 2. Fasten with two screws through the actuator base.