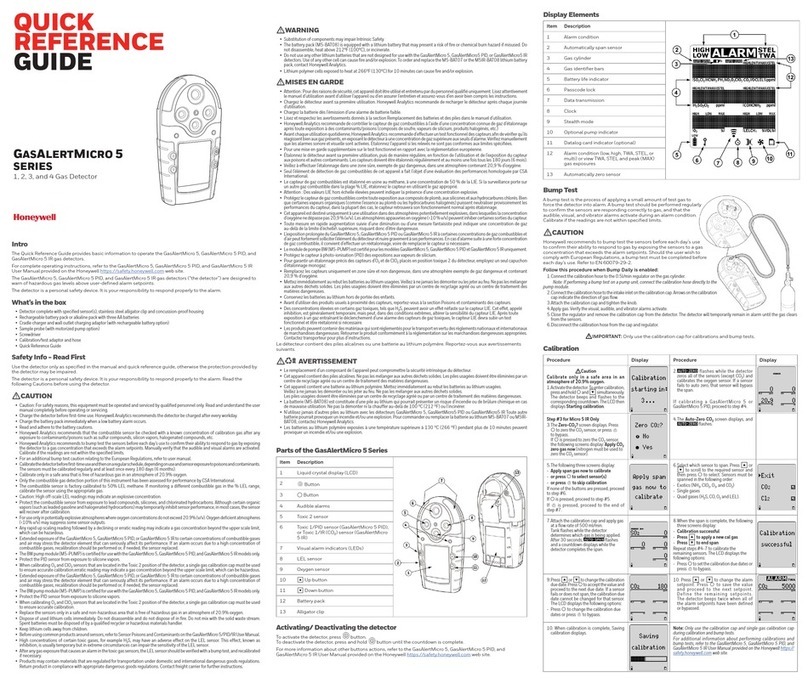

Installation Guide

Read and understand all the instructions in the BW RigRat User’s Guide before you start install.

These equipment items may receive hazardous voltages on their terminals. If you do not follow the instructions correctly,

you may expose yourself and others to serious injury as well as damage to equipment. Before starting your installation,

ensure that the model and power supply are suited to your purpose. This equipment should only be connected in

accordance with applicable regulations by qualified personnel.

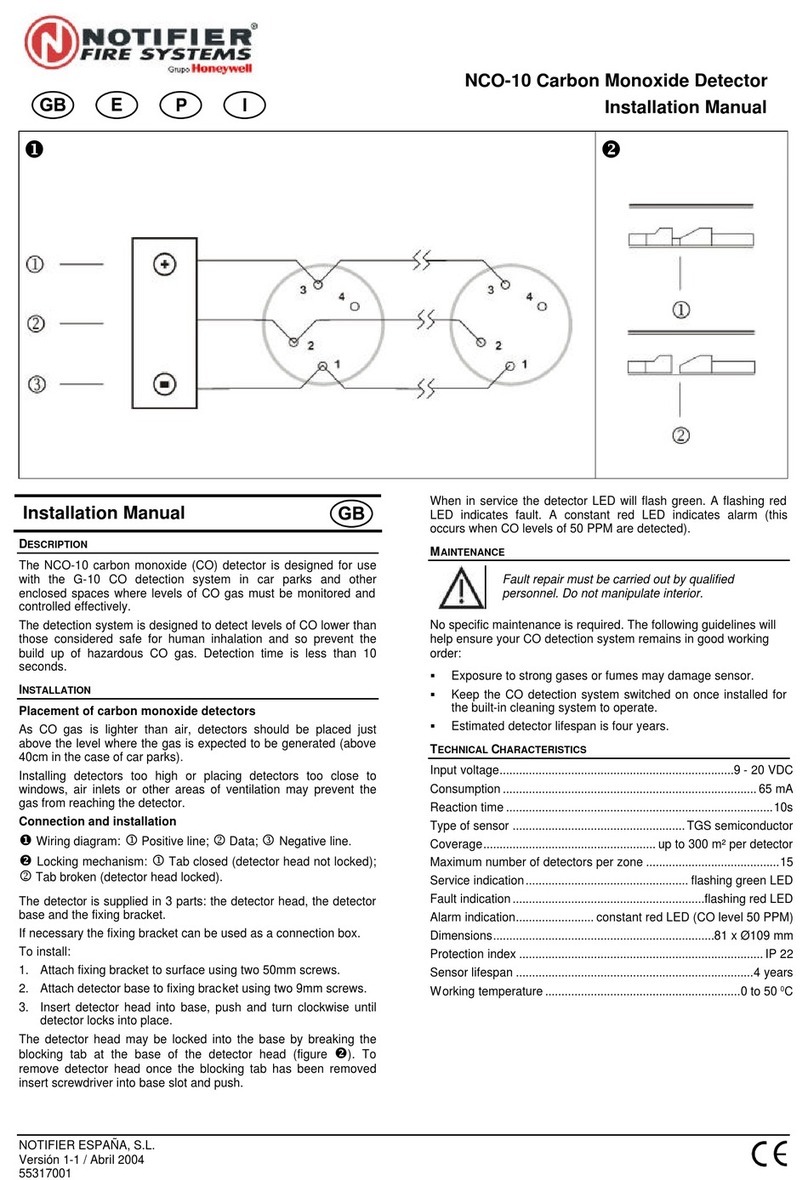

1. Connection

• Standard: plug-in cage clamp terminals (max. capacity 2.5 mm2)

• A flat head screwdriver (0.6 x 3.5 mm) is recommended to open the cage clamp terminal

• Optional: plug-in screw terminals (max. capacity 2.5 mm2)

2. Installation

The equipment is intended for association in accordance with intrinsic safety; the installation mustbe in compliance with

standard EN 60079-14, in particular paragraph 12.

3. Fixing and mounting

The equipment is intended for installation on an EN 50022 rail attached horizontally on a vertical plane, in order to respect

the direction of natural convection.

Do not obstruct the air vents. Use a screwdriver to insert and remove the equipment as indicated.

4. Location

The equipment must be installed in a non-explosive atmosphere, in a safe environment free of condensation and

corrosive or conductive dust. Intrinsic safety is ensured in the operating temperature range specified in paragraph 1.6.

However, you should remember that the service life of electronic equipment is reduced by half when its temperature is

increased by 10° C.

You should therefore install the equipment in suitably ventilated equipment rooms, avoid the proximity of elements that may

heat the equipment by radiation or which are likely to generate electromagnetic radiation greater than 10V/m.

5. Electrical connection

Electrical connections must be made when the equipment is DE-ENERGIZED, using wires with a maximum diameter of 2.5

mm2. For connections, refer to the wiring diagram.

6. Mechanical properties

The intrinsic safety terminals must only be connected to intrinsic safety equipment or equipment that is in compliance with

paragraph 5.7 of standard EN 60079-11. Moreover, the association of equipment and the connection cable must be

compatible in terms of intrinsic safety.

7. Cable path

The properties of cables and their routing from the ATEX zone (I.S. cables) must comply with the recommendations set out

in paragraphs 6.1, 6.2.1 and 6.3 of standard EN 600079-11.

Full precautions must be taken to prevent electromagnetic disturbance with other cables that may

generate dangerous voltages or currents. The I.S. cables must be clamped in order to prevent random contact with other

cables in the event the terminal is cut or damaged.

8. Adjustments and configuration

See technical data sheet or instructions for use.

9. Maintenance

Precautions to take during maintenance. Unmounting must be carried out DE-ENERGIZED.

In the event you suspect a failure or permanent fault, return the equipment to our services or representatives, who are the

only maintenance providers certified to perform expert assessments or repairs.

10. Un-mounting

Un-mount the unit from the enclosure by using a screwdriver as shown: