Content

For your safety ..................................................................................................................................................................................

Technical data and information ........................................................................................................................................................ 3

Operational and storage conditions ................................................................................................................................................. 4

Terminology ...................................................................................................................................................................................... 4

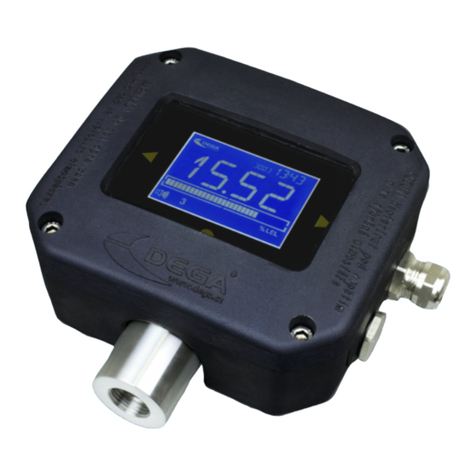

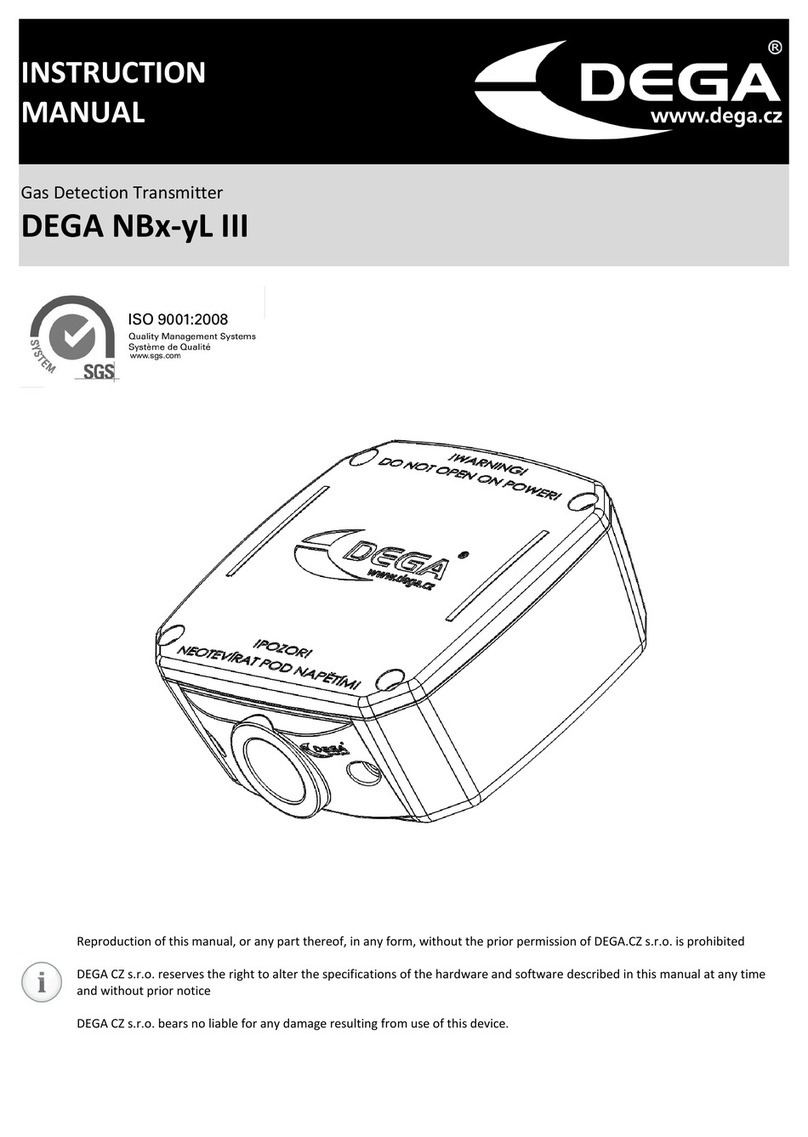

Product description ........................................................................................................................................................................... 4

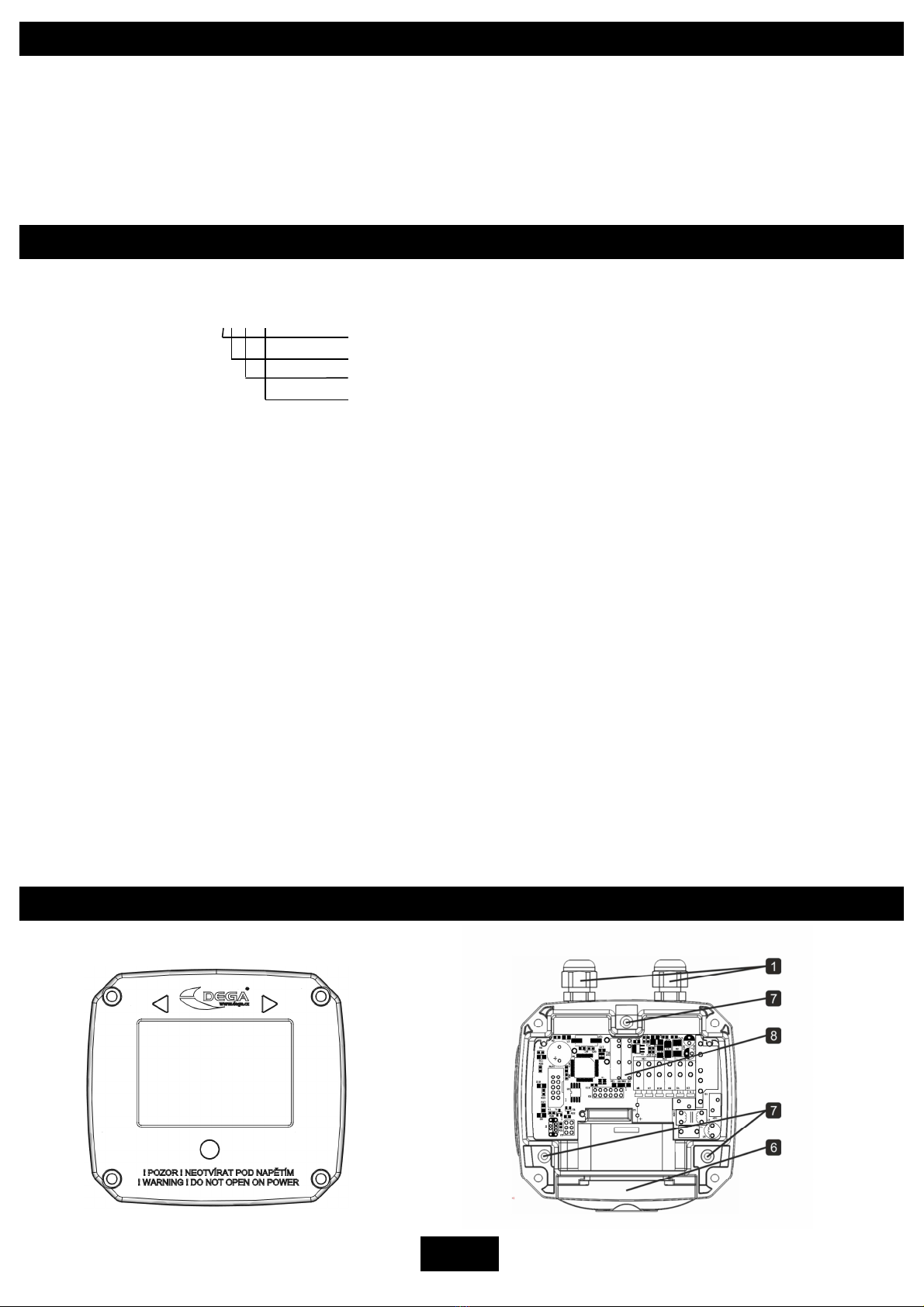

Installation, assembly and disassembly of the detector ................................................................................................................... 5

1. Assembly of the detector ...................................................................................................................................................... 5

. Replacement of the sensor module ...................................................................................................................................... 5

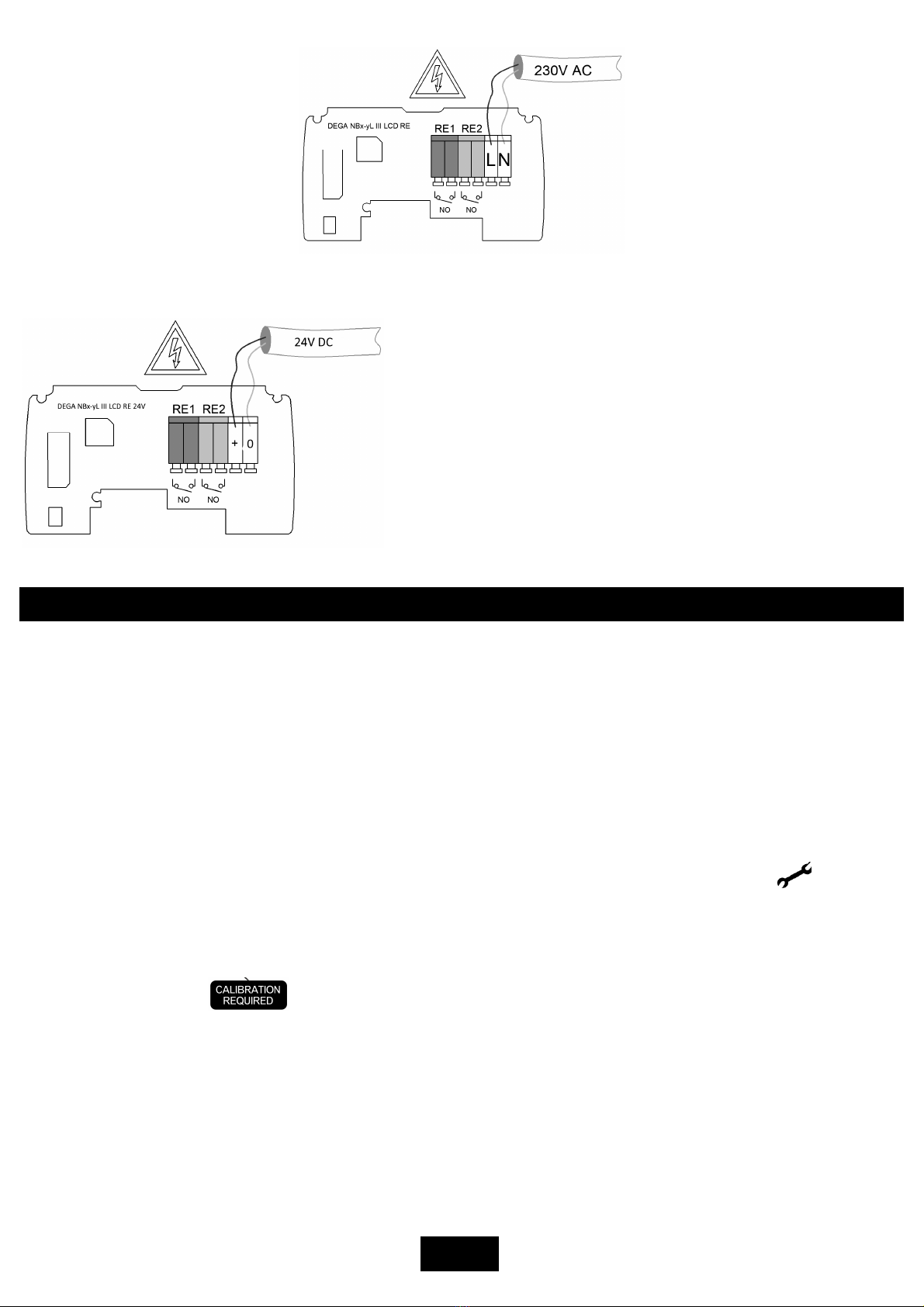

3. Connecting the detector - 30V AC ..................................................................................................................................... 6

4. Connecting the detector - 4V. Only for version NBx-yL III LCD RE 4V. ............................................................................. 6

Detector functions ............................................................................................................................................................................ 6

1. Turning on the detector ........................................................................................................................................................ 6

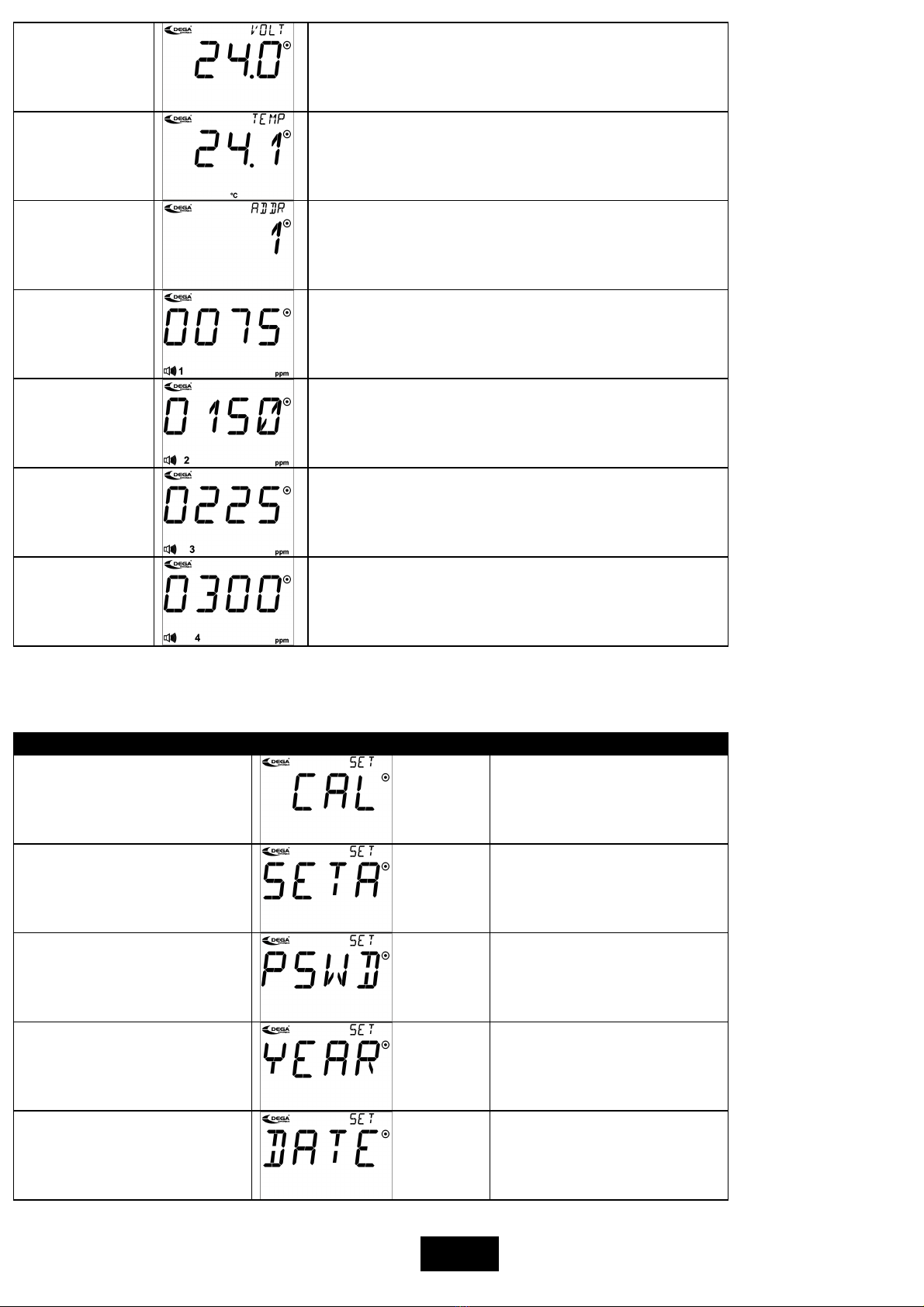

. Gas detection ........................................................................................................................................................................ 6

3. Malfunction ........................................................................................................................................................................... 6

4. Monitoring the calibration periods ....................................................................................................................................... 6

5. Reading the record of measured concentrations and alarms .............................................................................................. 6

Detector controls .............................................................................................................................................................................. 7

6. Menu History „HIST“ ............................................................................................................................................................. 8

7. Information menu „INF“ ....................................................................................................................................................... 8

8. Settings menu „SET“ ............................................................................................................................................................. 9

9. Menu Test „TEST“ ............................................................................................................................................................... 11

Operation and maintenance of the detector.................................................................................................................................. 11

1. Usage limits ......................................................................................................................................................................... 11

. Operation ............................................................................................................................................................................ 1

3. Operation/Maintenance ..................................................................................................................................................... 1

Accessories ...................................................................................................................................................................................... 1

1. Additional bushing DEGA BUSHING for NBx III ....................................................................................................................... 1

Basic type of detectors ................................................................................................................................................................... 1

1. Detectors with a catalytic sensor NBx-CL III LCD ................................................................................................................ 1

. Detectors with an electrochemical sensor NBx-EL III LCD .................................................................................................. 13

3. Detectors with an infrared sensor NBx-IL III LCD ................................................................................................................ 15

4. Detectors with a semiconductor sensor NBx-SL III LCD ...................................................................................................... 15

5. Detectors with a PID sensor NBx-PID III LCD ...................................................................................................................... 15

Add-on modules .............................................................................................................................................................................. 16

Attachments .................................................................................................................................................................................... 16

Table of error codes.................................................................................................................................................................... 16

General warranty terms and conditions ......................................................................................................................................... 17

For your safety

The detector must e mounted with the sensor module downwards

To maintain IP protection, the detector must be mounted with the sensor module downwards

Beware of static electricity

Electronic components are sensitive to static electricity. Do not touch them directly - they may get damaged.

The device is intended to e installed y a trained person

The product is designed only for installation by a certified technician. The manufacturer is not liable for damages resulting

from incorrect or improper handling.

In case of malfunction, immediately unplug from the power supply

If you notice an unusual smell or smoke emitting from the product, unplug it from the power supply, battery backup and all

other attachments. Continued operation could result in injury or property damage.