RGD GP5 MP1 RSE 020408B4 270212

2

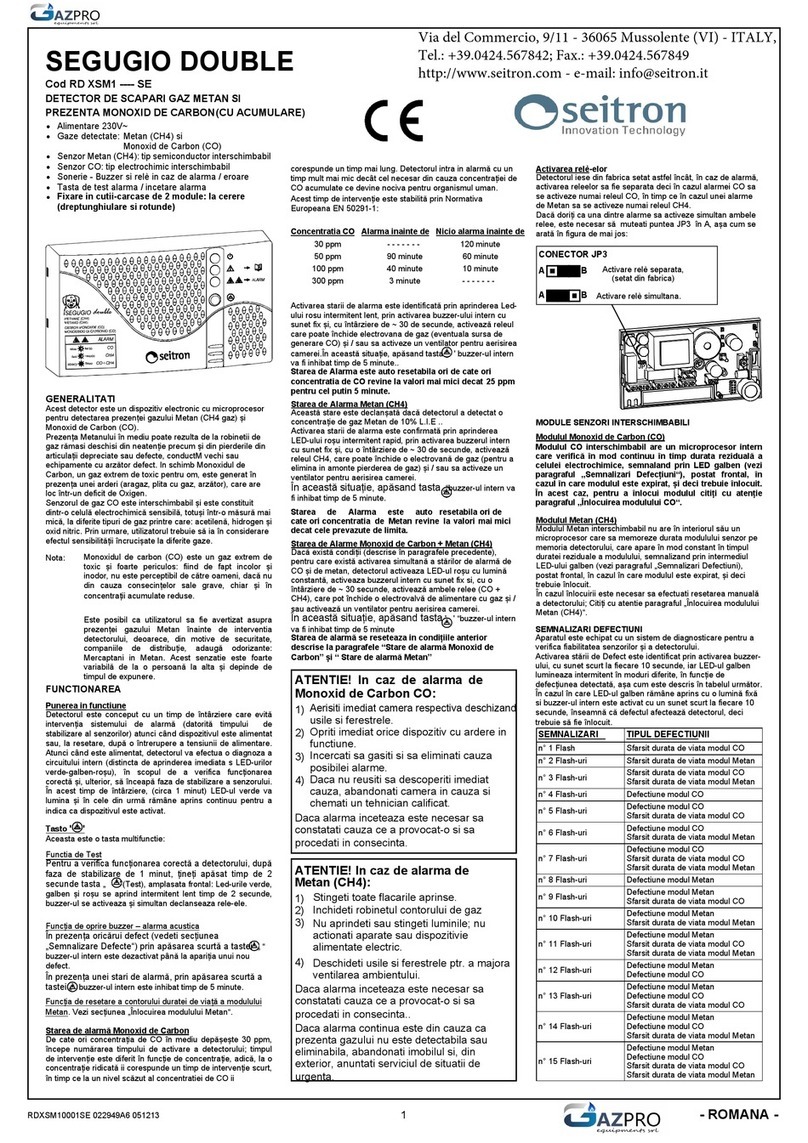

Fig. 5:Wiring diagram for several Beagle plus and one manual reset Normally Closed 230V~ electro-valve.

Fig. 3: Wiring diagram with one Beagle plus and one

manual reset Normally Closed 230V~ electro-valve. Fig. 4: Wiring diagram with one Beagle plus and one man-

ual reset Normally Open 230V~ electro-valve.

Fig. 6:Wiring diagram for several Beagle plus and one manual reset Normally Open 230V~ electro-valve.

WIRING DIAGRAM

- ENGLISH -

NL 3 4 5

230V~ N.C.

E.V.

230V~

L N

NL 345

N

230V~

L

E.V.

3

230V~

L N

L N 3 4 5L N 4 5

230V~

L N

E.V.

4

NL

230V~

L N 35

230V~

L N

L N 345

E.V.

230V~ N.C.

TECHNICAL FEATURES

Power supply: 230V~ -15% +10% 50/60Hz

Power absorption: 2VA

Sensor type: SnO

2

semiconductor

replaceable

Detected gas: BEAGLE plus L: LPG

BEAGLE plus M: Methane

Alarm threshold: 10% L.E.L.

Contacts rating: 5A @ 250V~ SPDT

Indicators: Active: Green led on

Fail: Yellow led on

Alarm: Red led on

Alarm: Buzzer

Heating delay at turn-on: ~ 30 seconds

Relay activation delay: ~ 5 seconds

Sensor lifetime: 5 years

Operating temperature: 0°C .. 40°C

Storage temperature: -10°C .. +50°C

Humidity limits: 20% .. 80% RH

(non condensing)

Protection rating: IP 42

Case: Material: ABS + PC

Color: Signal white (RAL 9003)

Size: 85 x 107 x 38 mm

(W x H x D)

Weight: ~ 260 gr.

Product Reference Standard: EN 50194-1 (2009)

EMC Reference Standard: EN 50270 (2006)

LVD Reference Standard: EN 60335-1 (2002)

OPERATION

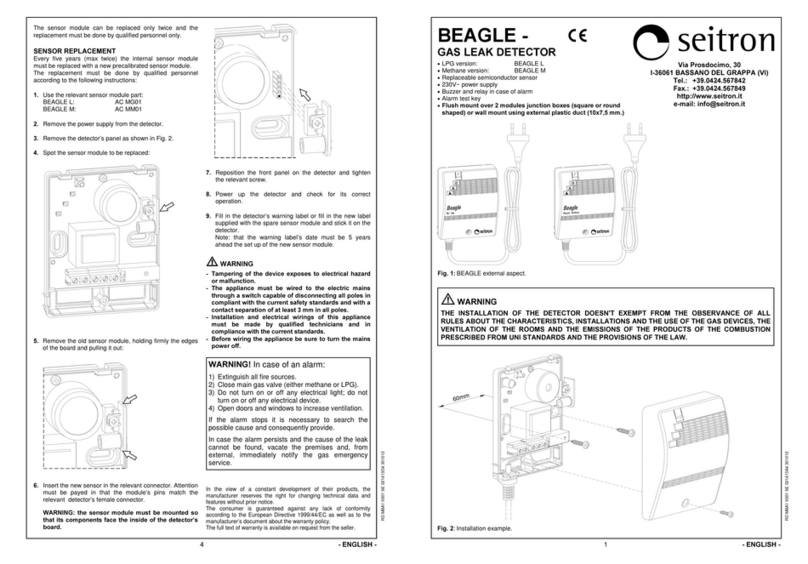

This BEAGLE plus (Fig. 1) is a flammable gas leakage

domestic detector. When exposed to a gas concentration

much lower than the danger level, the detector turns on a

red light and a buzzer, then, after 5 seconds it, turns on a

relay which can be used to stop the gas supply.

Note: The user might smell the presence of gas before the

detector does; this happens because the distribution

companies use to add odorizers to natural gas and LPG.

This sensation is extremely variable from person to person,

and depends on the exposure time.

To test the correct operation of the detector, press the T

(Test) button on the frontal panel: the green, yellow and

red LEDs will turn on; the buzzer will buzz and after 5

seconds the relay contact is activated.

The BEAGLE plus is equipped with a delay line which

avoids the intervention of the alarm system (in order for the

gas sensor to heat up) whenever the device is turned on or

even after a mains black-out, as soon as the power comes

back. After that delay (about 30 seconds) the yellow LED

turns off and the green LED remains on to show that the

detector is powered.

The BEAGLE plus features an auto-diagnostics system

which verifies the sensor reliability.

When the yellow indicator is turned on (sensor fail) the

possible causes must be searched among the following:

- sensor fail;

- sensor disconnected;

- detector malfunctioning.

INSTALLATION

This device is intended for wall mount only, with relevant

electrical wiring made through the fixed wiring, not exposed

to people and connected to the fixed electrical wiring. The

device safety and operational features are only granted

when the electrical wiring is made through the proper

opening for cables located in the plastic plate.

To access to the internal terminals, remove the front panel

by loosening the screw (Fig. 2).

Make the electrical wiring following the suggested wiring

diagrams in Fig. 3, 4, 5 or 6.

Please note that the intervention delay is strictly dependant

both on a correct positioning of the detector in the room and

to the type of gas to be detected.

In case of 'heavy' gases (as for LPG) an installation in low

places is advisable (about 30 cm from floor level), meanwhile

for ’light’ gases like methane in high places (about 30 cm

from ceiling level).

Please avoid to install this gas detector in any position in

which its operational features could be compromised, such

as the following:

- in an enclosed space (e.g. in a cupboard or behind a

curtain;

- directly above a sink;

- next to a door or window;

- next to an extractor fan;

- in an area where the temperature may drop below - 10°C

or exceed + 40°C;

- where dirt and dust may block the sensor;

- in a damp or humid location.

Do not use the following substances in the device

immediate adjacency:

- alcohol, fuels

- solvents and diluents

- adhesives, silicones products and colours

- cleaning detergents

- perfumes

- spray products in general

Clean the device only using a cloth damped with water.

In order to grant a real safety, a gas detector must be

coupled to an electro-valve capable of blocking the gas flow

in the event of an alarm.

Both the gas unit and the solenoid valve must comply with

the law prescriptions in force in the country concerned.

BEAGLE plus detector can be connected to two types of

electro-valve:

- 230V~ Normally Open electro-valve;

- 230V~ Normally Closed electro-valve;

In order to check the proper efficiency of the device sensor

a specific test gas bottle (optional) is made available which

must be used according to the enclosed instructions.

WARNING: Any other method for testing, such as the

use of cigarette lighters, flammable vapours etc., can

lead to wrong conclusions as well as to the irreversibile

damage of the sensor itself.

WARNING

The installer is reminded to fill in and apply the sticking label

supplied with the product by writing the installation date of

the product, the date before which the sensor module must

be replaced, the date before which the sensor module must

be replaced the second and last time and finally the date

before which the entire detector must be replaced.

The latter is stated on 15 solar years from the installation

date of the product.

This label must be applied, at installer care, on a visible side

of the gas detector once it has been fixed in its typical

installation position.

Warning label:

RGD GP5 MP1 RSE 020408C4 270212

3 - ENGLISH -