10

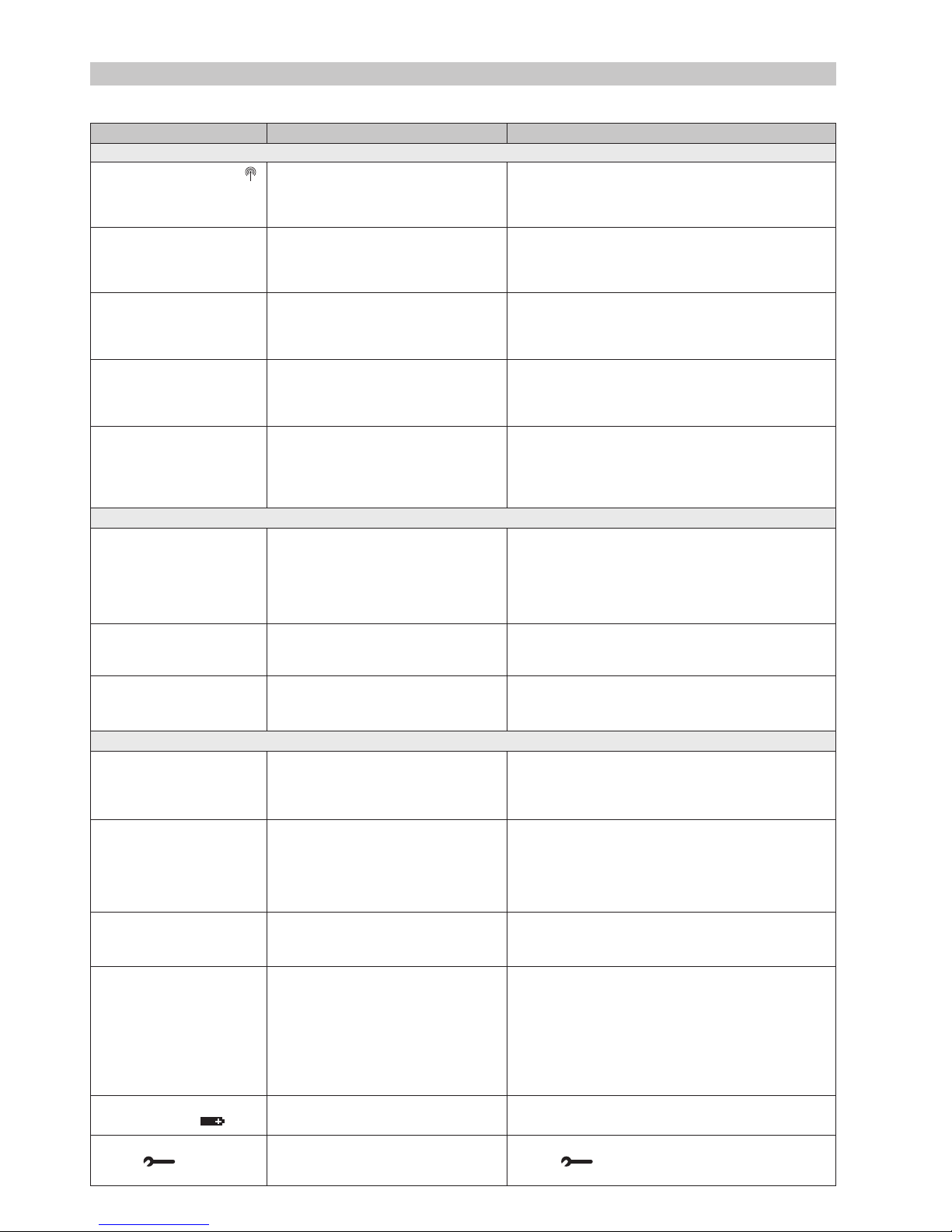

Section 9: Trouble Shooting

Symptom (Fault Message)

After binding procedure the

symbol on HR80UK display

is off.

After binding procedure the red

LED of the HC60NG is on and

the green one is flashing once

every 3 sec.

After binding procedure the red

LED of the HC60NG is on and

green LED is flashing twice

every 3 sec.

After binding procedure the red

LED of the HC60NG is on and

green LED is flashing 3 times

every 3 sec.

After binding procedure the red

LED of the HC60NG is on and

green LED is flashing 4 times

every 3 sec.

HR80UK does not receive

the correct setpoint from the

CM67z.

The boiler does not switch on

when the HR80UK setpoint is

set to ON.

HC60NG’s green LED is not

flashing every 5 sec during the

system test

The red LED of the HC60NG

is on.

The red LED of the HC60NG is

flashing 2.5 sec on/2.5 sec off.

The CM67z shows a different

actual temperature than the

HR80UK setpoint

Blank display on CM67z or

HR80UK.

CM67z display shows a flash-

ing battery symbol ( ).

CM67z displays a spanner

symbol ( ).

Possible Cause

Incorrect or incomplete binding procedure.

Bad position of the CM67z during binding.

Incorrect or incomplete binding procedure.

Bad position of the CM67z during binding.

An attempt was made to bind more than 4

CM67z units to the HC60NG.

An attempt was made to cross bind the

HC60NG with system timing message

when no other binding was present.

An attempt was made to bind two system

timing messages to one HC60NG.

Bad position of the CM67z.

No binding data in the HR80UK.

HR80UK bound to the wrong zone.

Missing binding data in the HC60NG.

Bad position of the CM67z.

The HC60NG receives no messages:

RF signal is blocked (e.g due to bad posi-

tion of the CM67z) or CM67z and HR80UK

batteries are exhausted.

The HC60NG has not received signals

from one (or more) transmitters in the

system but still receives signals from other

transmitters: RF signal is blocked (e.g due

to bad position of the CM67z) or CM67z

and HR80UK batteries are exhausted.

Location of HR80UK and CM67z

No batteries.

Wrong battery orientation.

Improper battery compartment insertion

(CM67z only).

Exhausted batteries.

Batteries need replacing.

Fault in the CM67z room unit.

Remedy

Repeat the binding procedure following the installation instructions.

Repeat the binding procedure keeping approx. 1 m distance

between CM67z and HR80UK.

Repeat the binding procedure following the installation instructions.

Repeat the binding procedure keeping approx. 1 m distance

between CM67z and HC60NG.

Press and hold the HC60NG push button for 15 sec to

reset the memory. Repeat all the binding operations for this

HC60NG making sure that no more than 4 CM67z units are

bound.

Reset the HC60NG binding data by pressing the push button for

15 sec. Repeat the complete start up procedure as described in

Section 8.2: Changing the Configuration.

Make sure that only one CM67z is configured as system

timing master. Reset the HC60NG binding data by press-

ing the push button for 15 sec. Repeat the complete start

up procedure as described in

Section 8.2: Changing the

Configuration

.

Reposition the CM67z and repeat the test.

Repeat the binding procedure.

Repeat the binding procedure, making sure that the HR80UK

is bound to the proper zone.

Repeat the binding procedure (CM67z with the HC60NG

boiler controller or HC60NG zone valve controller).

Reposition the CM67z and repeat the test.

Return the CM67z room unit to the position where communi-

cations is reliable or replace discharged batteries.

Return the CM67z room unit to the position where communi-

cations is reliable or replace discharged batteries.

Link the actual temperature measured by the CM67z with the

HR80UK (only Zone 1 can be configured).

Check that the batteries are in the battery compartment and

that the paper tab (CM67z only) has been pulled out.

Check that the batteries have been installed in the correct orientation.

Remove battery compartment and re-insert.

Replace the batteries.

Replace the batteries.

Remove and re-insert the battery compartment. If the spanner

symbol ( ) does not clear itself in a few minutes call the

Honeywell Technical Help-Desk, details on the back page.

During Binding

During Testing

During Normal Operation

9.1 Trouble Shooting Guide