- 4 -

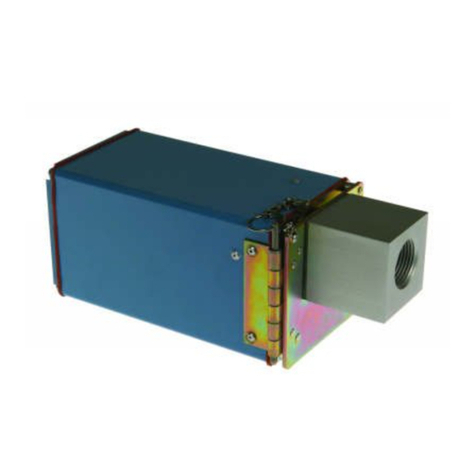

SPECIFICATIONS:

Operating Temperature: 14°to 131°F / -10°to 55°C

Relative Humidity: 5 to 93% (UL tested at 93%); non-condensing

TROUBLESHOOTING:

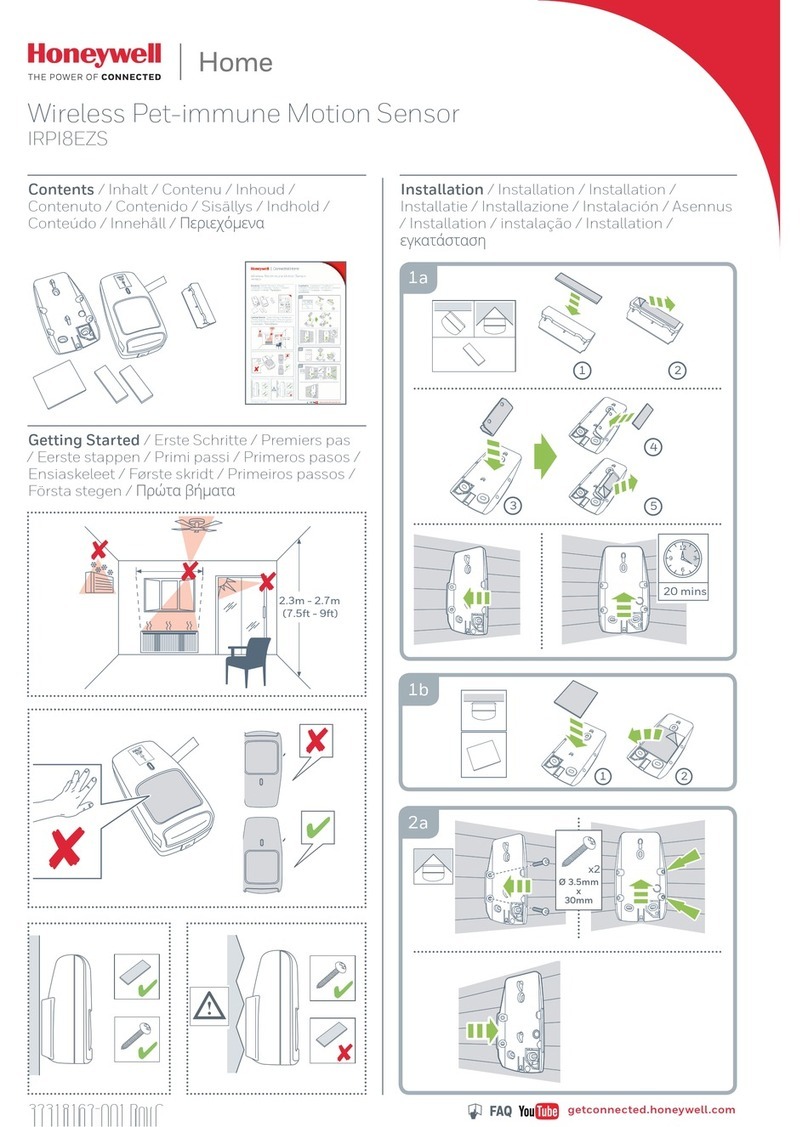

NORMAL

Mask

1

Voltage

2

Failure

3

Closed Open Closed Closed

*TROUBLE CONDITIONS:

1

Mask condition: Sensor IR window is blocked or masked.

2

Low Voltage: The sensor is disabled. [Note: If voltage drops

below 7.9V, the Trouble relay will open.]

3

Self-Test Failure conditions:

• Microwave supervision failure: The

sensor is operating in PIR mode

only.

• PIR self-test failure: The sensor is

disabled.

• Temperature compensation failure:

The temperature compensation is

disabled.

Depending on the Trouble

condition, take the following

corrective actions:

• Verify the sensor is not blocked

or masked.

• Verify the power supply is

sufficient (at least 9V at the

sensor).

• Cycle power to the sensor.

• Walk test the sensor.

If the Trouble condition does not

clear, replace the sensor.

APPROVAL/ LISTINGS:

•FCC part 15, Class B verified

•IC ICES-003, Class B verified

•UL 639

•ULC S306-03

•SIA-PIR-01 Passive Infrared detector standard features for false alarm

immunity.

Product must be tested at least once each year / Le fonctionnement du produit doit être vérifié au moins une fois par année /

El producto debe ser probado al menos una vez al año / O produto deve ser testado pelo menos uma vez por ano

All wiring must be in accordance with: the National Electrical Code (ANSI/NFPA70); the Canadian Electrical Code, Part I (where applicable); UL681,

Standard for Installation and Classification of Burglar and Holdup Alarm Systems; ULC-S302, Standard for Installation and Classification of Burglar

Alarm Systems for Financial and Commercial Premises, Safes and Vaults; ULC-S310, Standard for Installation and Classification of Residential Burglar

Alarm Systems; local codes and the authorities having jurisdiction.

The products are intended to be powered by a power-limited output of a UL/CUL Listed Burglar Alarm control unit, or via a Listed UL603/ULC-S318

power-limited power supply that provides 4 hours of standby power.

The sensor must be mounted indoors, within the protected premises, and on a wooden stud, solid wood or with a robust wall anchor.

UL Notes: All interconnecting devices must be UL Listed. The anti-mask feature has not been evaluated by UL.

For the latest documentation and online support information, please go to:

Pour de l assistance en ligne, visitez :

Para recibir soporte en línea, visite:

Para qualquer informação adicional, contacte:

http://www.security.honeywell.com/hsc/resources/MyWebTech/

For the latest U.S. warranty information, please go to: www.honeywell.com/security/hsc/resources/wa or

Please contact your local authorized Honeywell representative for product warranty information.

Pour obtenir de l'information sur la garantie de ce produit, veuillez communiquer avec le représentant

autorisé de Honeywell de votre région.

Por favor contacte con su distribuidor Honeywell Security para información sobre la garantía del producto.

Contacte o representante autorizado Honeywell local para obter informações relativas a garantia.

2013 Honeywell International Inc. Honeywell and DUAL TEC are registered trademarks of Honeywell International Inc.

All other trademarks are the properties of their respective owners. All rights reserved. Made in China.

FEDERAL COMMUNICATIONS COMMISSION STATEMENTS

The user shall not make any changes or modifications to the equipment unless authorized by the Installation Instructions or User's Manual.

Unauthorized changes or modifications could void the user's authority to operate the equipment.

CLASS B DIGITAL DEVICE STATEMENT

This equipment has been tested to FCC requirements and has been found acceptable for use. The FCC requires the following statement for your

information:

This equipment generates and uses radio frequency energy and if not installed and used properly, that is, in strict accordance with the

manufacturer's instructions, may cause interference to radio and television reception. It has been type tested and found to comply with the limits for

a Class B computing device in accordance with the specifications in Part 15 of FCC Rules, which are designed to provide reasonable protection

against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

• Reorient the receiving antenna until interference is reduced or eliminated.

• Move the radio or television receiver away from the receiver/control.

• Move the antenna leads away from any wire runs to the receiver/control.

• Plug the receiver/control into a different outlet so that it and the radio or television receiver are on different branch circuits.

• Consult the dealer or an experienced radio/TV technician for help.

INDUSTRY CANADA CLASS B STATEMENT

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

FCC / IC STATEMENT

This device complies with Part 15 of the FCC Rules, and RSS210 of Industry Canada. Operation is subject to the following two conditions: (1) This

device may not cause harmful interference, and (2) This device must accept any interference received, including interference that may cause

undesired operation.

Cet appareil est conforme à la partie 15 des règles de la FCC & de RSS 210 des Industries Canada. Son fonctionnement est soumis aux conditions

suivantes: (1) Cet appareil ne doit pas causer d’interférences nuisibles. (2) Cet appareil doit accepter toute interférence reçue y compris les

interférences causant une réception indésirable.

P/N 800-13827 03/14 Rev C

To protect the environment, a detailed installation guide is available on

the Honeywell website – Please consider before printing the document!

2 Corporate Center Drive, Suite 100

P.O. Box 9040, Melville, NY 11747

www.honeywell.com/security