R7195A,B MOTOR POSITIONER

63-2582 8

a. Frequent re-positioning (hunting) of the motor.

b. Oscillation of the process variable around the

setpoint.

Check for unstable process conditions during initial startup of

the process. If unstable operation occurs, increase the

deadband adjustment (P2) until the cycling rate diminishes.

Hard Manual Check

Hard Manual allows the operator to override the controller

action to open or close fully the final control element (valve,

damper, etc.).

4-20 mA—Model 7195A

Connect terminal W to terminal B to drive the motor fully open.

Disconnect terminal W or terminal R to drive the motor fully

closed.

135-ohm Potentiometer—Model R7195B

Connect terminal W to terminal R to drive the motor fully

closed. Disconnect wire from Terminal W to drive the motor

fully open.

Troubleshooting

CAUTION

Equipment Damage Hazard.

Improper procedure can damage internal circuits.

To prevent triac damage, do not attempt to short

R7195 terminals 1, 2 or 3.

Motor Checkout Procedure

1. Identify wires on terminals 1 through 6 by terminal

number; then disconnect them from the terminals.

2. Connect an ohmmeter across wires 4 and 5 (feedback

slidewire).

3. Apply rated voltage across wires 1 and 2. Observe

gradual increase or decrease in feedback resistance.

4. Apply rated voltage across wires 2 and 3. Observe

gradual increase or decrease in feedback resistance.

If the motor functions properly, continue with the

troubleshooting procedure that follows.

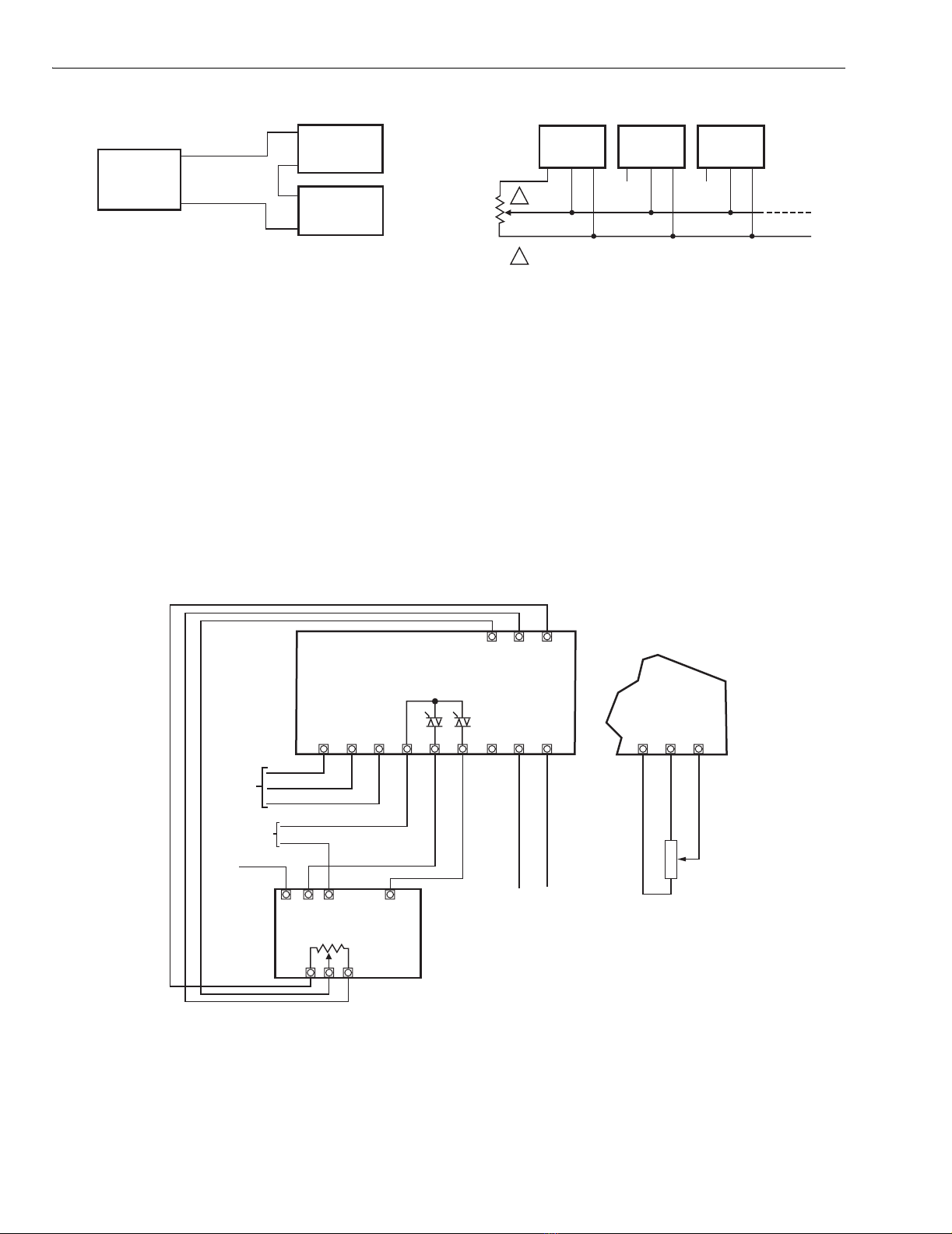

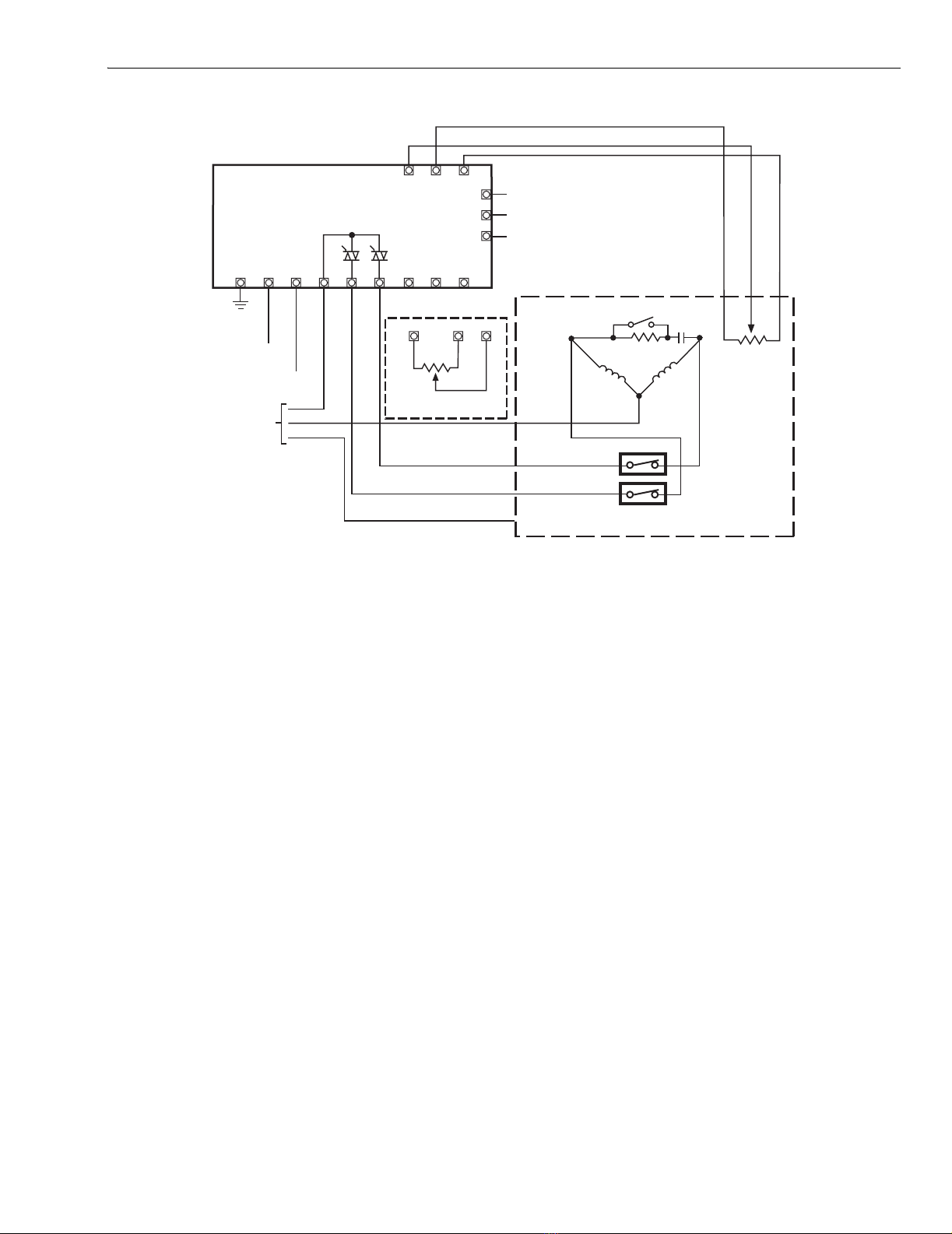

4-20 mA Input Applications

PRINTED WIRING BOARD

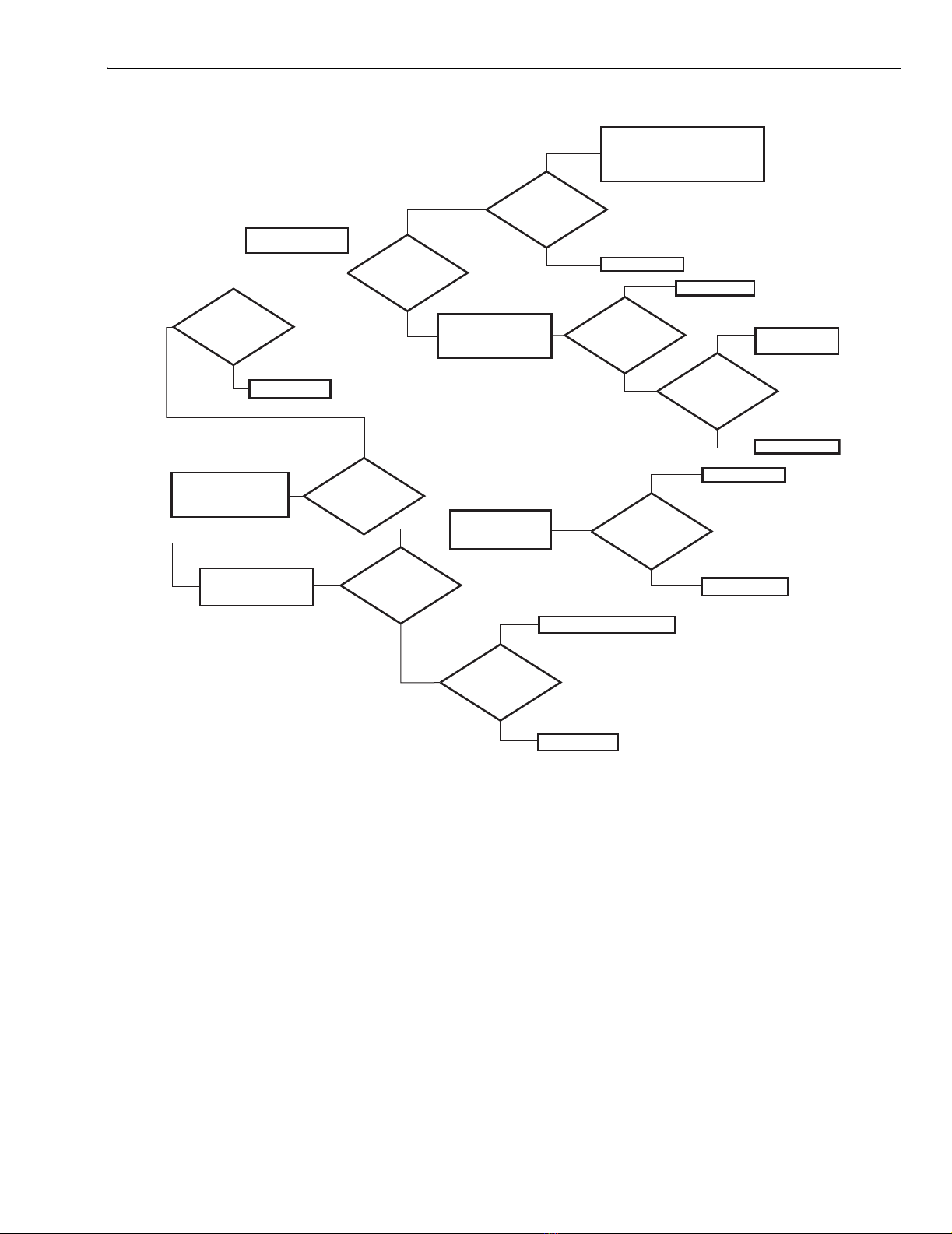

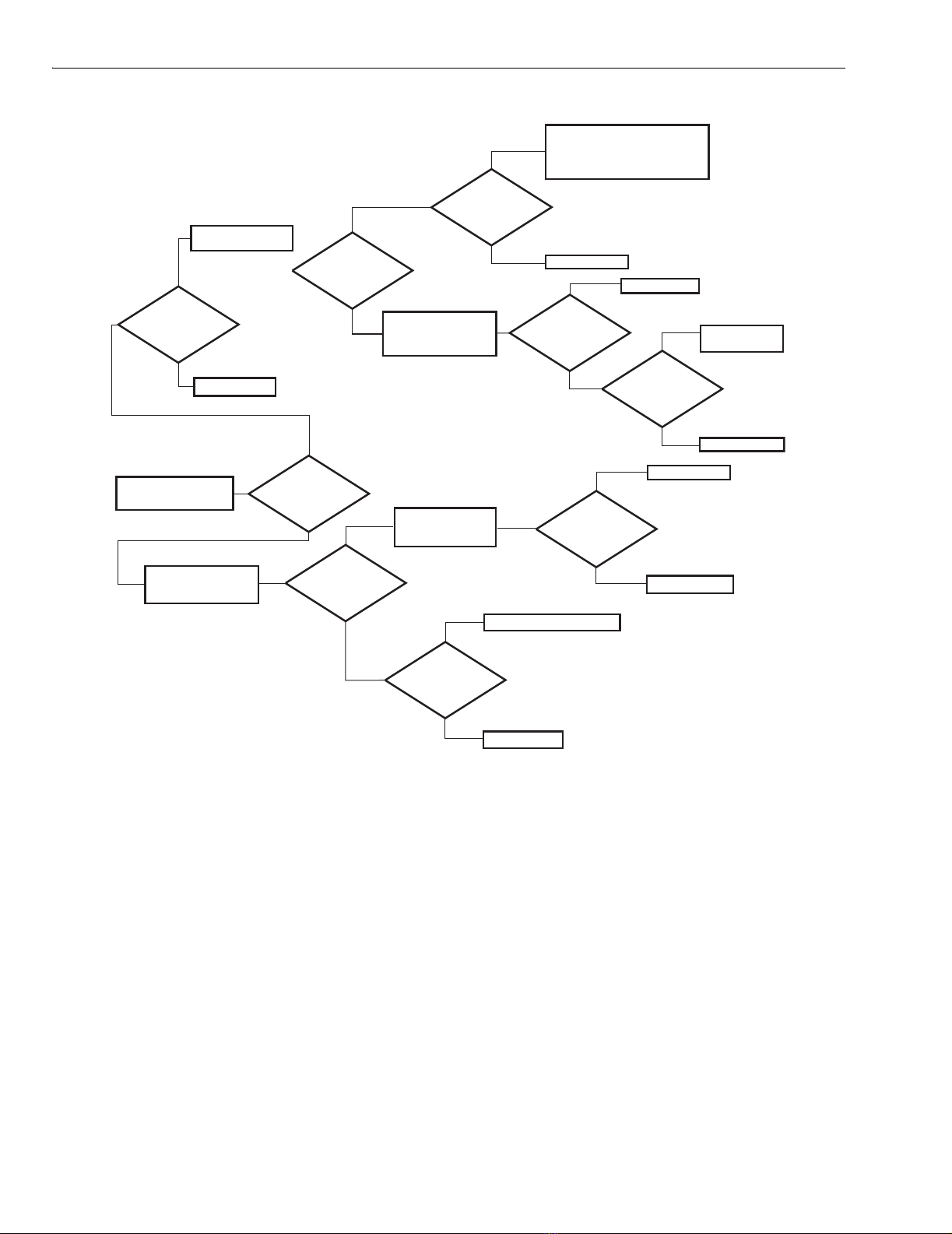

Refer to Fig. 10 and 11.

1. Connect the operating voltage leads to the appropriate

terminals and apply power (Fig. 10).

2. Set the motor at mid-range as follows:

a. Connect input source to terminals W and R, as

applicable to the motor.

b. Adjust the input source to mid-range.

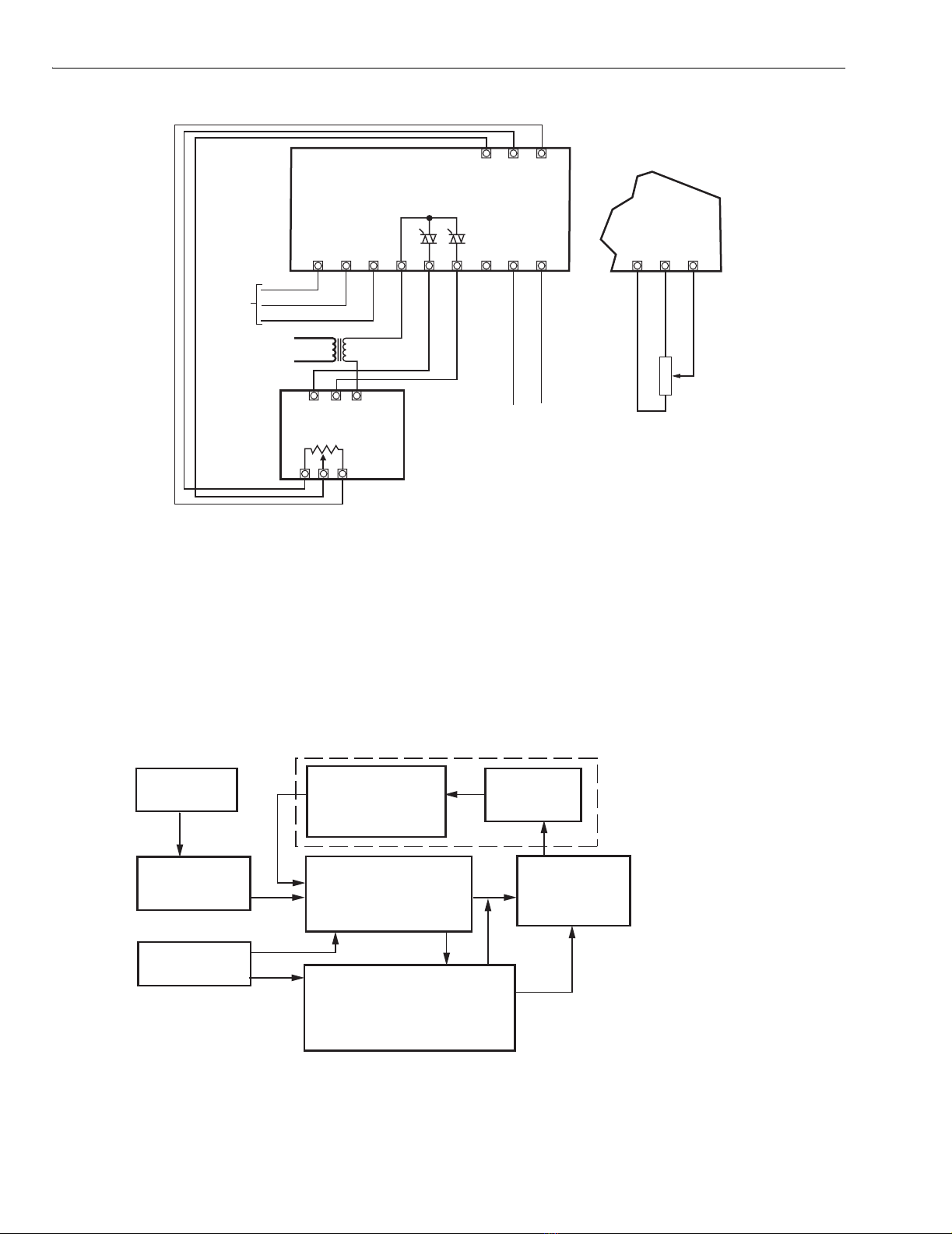

3. Refer to Fig. 11, a logic diagram to help you isolate

output circuit component failures on the printed wiring

board. Please refer to the appropriate literature for your

motor.

4. The types of component failures are listed below:

a. Shorted triac switches Q3 and Q4.

b. Q3 and Q4 break over at less than rated voltage.

c. Q3 and Q4 do not fire.

d. MOV (CR12) shorts.

5. If the logic diagram does not identify your

system-related problem, the failure is not in the output

circuit and the controller should be replaced or you may

use the schematic to troubleshoot the board.

NOTE: If your motor-motor controller system runs to fully

open or fully closed position, but fails to balance with

proper input conditions, it may be necessary to

reverse either motor power connections (1 and 3) or

feedback slidewire connections (4 and 6) at the

controller.

REVERSING DIRECTION OF THE MOTOR

Motor direction may be reversed as follows:

1. Interchange motor winding connections on terminals 1

and 3.

2. Interchange feedback potentiometer connections on ter-

minals 4 and 6.

135-Ohm Input Applications

PRINTED WIRING BOARD

Refer to Fig. 10 and 11.

1. Connect the operating voltage to the appropriate

terminals and apply power.

2. Set the motor at mid-range as follows:

a. Connect input source to terminals B, W and R.

b. Adjust input source to mid-range.

3. Refer to Fig. 11, a logic diagram to help you isolate

output circuit component failures on the printed wiring

board. Please refer to the appropriate literature for your

motor.

4. Types of component failures are listed below:

a. Shorted Triac switches Q3 and Q4.

b. Q3 and Q4 break over at less than rated voltage.

c. Q3 and Q4 do not fire.

d. MOV (CR12) shorts.

5. If the logic diagram does not identify your

system-related problem, the failure is not in the output

circuit and the controller should be replaced or you may

use the schematic to troubleshoot the board.

NOTE: If your motor-motor controller system runs to fully

open or fully closed position, but fails to balance with

proper input conditions, it may be necessary to

reverse either motor power connections (1 and 3) or

feedback slidewire connections (4 and 6) at the

controller.

REVERSING DIRECTION OF THE MOTOR

Motor direction may be reversed as follows:

1. Interchange motor winding connections on terminals 1

and 3.

2. Interchange feedback potentiometer connections on

terminals 4 and 6.