HORIZON INSTRUMENTS, INC. Title: P-1000 INSTALLATION & INSTRUCTION MANUAL Number: P103050 Revision: EPage: 7 of 23

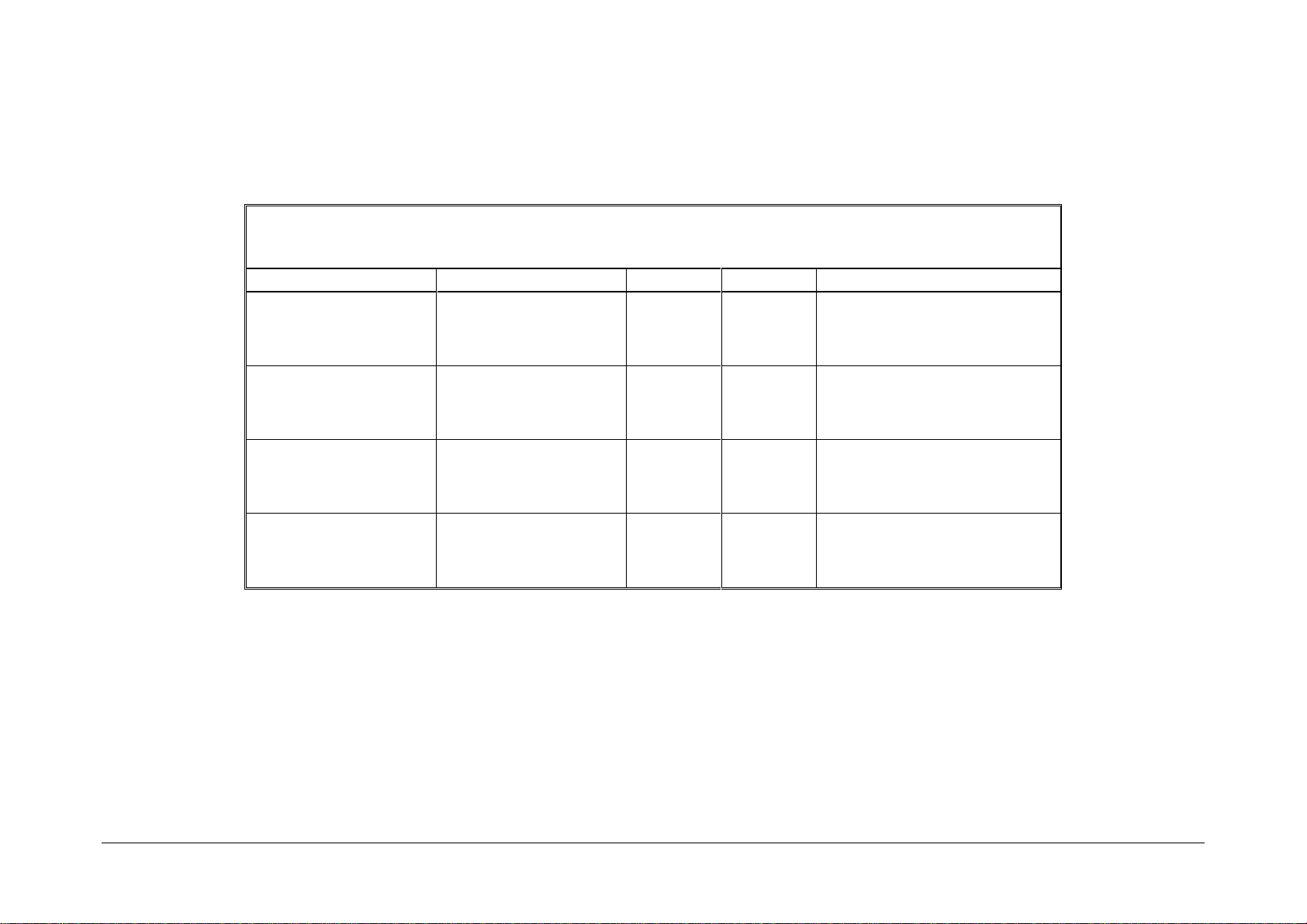

The P-1000 Electronic Digital Engine Tachometer is designed to meet the following environmental test categories of RTCA DO-160-C.

CONDITIONS PARAGRAPH

NUMBER DESCRIPTION OF CONDUCTED TESTS CONDITIONS PARAGRAPH

NUMBER DESCRIPTION OF CONDUCTED TESTS

4 Tested to categories A1 & B1. Fluids Susceptibility 11 Equipment Identified as “X”.

No Test Required.

4.5.1 Ground Survival (-55 C) & Low Operating

Temperature Tests (-20 C) Sand & Dust 12 Equipment Identified as “X”.

No Test required.

4.5.2 Ground Survival (+85 C) & High Short

Time Operating Temperature Test (+70

C). Fungus 13 Equipment Identified as “X”.

No Test Required.

4.5.3 High Operating Temperature Test (+55

C) Salt Spray 14 Equipment Identified as “X”.

No Test Required.

4.6.1 Altitude

(+25,000Ft) Magnetic Effect 15 Tested Per Category “Z”.

No compass defection in each axis.

4.6.2 Decompression Tests

(8,000Ft to 25,000Ft) Power Input 16 Tested Per Category “B”.

EUT operated normally

during all test conditions.

Temperature

&

Altitude

4.6.3 Overpressure Tests

(-15,000Ft) Voltage & Spike, Conducted 17 Tested Per Category “B”.

EUT displayed no malfunctions or

degradations during testing.

Temperature Variation 5 Tested Per Category “B”. Equipment will

withstand better than 5 C/min

temperature change.

Audio Frequency

Conducted Susceptibility 18 Tested Per Category “B”.

EUT displayed no malfunctions or

degradations during testing.

Humidity 6 Tested per Category “A”.

95% Humidity Induced Signal Susceptibility 19 Tested Per Category “B”.

The EUT showed no signs of susceptibility

during this test.

7.2 Operational Shock Test, 6gs in 11ms. ½

sine, 3 shocks per axis, each direction. Radio Frequency

Susceptibility 20 Tested Per Category “U”.

The EUT showed o signs of susceptibility

during this test.

Shock

7.3 Crash Safety Test, impulse and Sustained

Shock. 15gs in 11ms. ½ sine performed

on each axis. Radio Frequency Emissions 21 Tested Per Category “B”.

The EUT’s emissions were within the test

requirements.

Vibration 8 Tested per “Standard Vibration”

requirements. Resonance scans detect no

resonance in each axis.

Lightning Induced Transient

Susceptibility 22 Tested Per Category “K”.

These tests had no

effect upon the EUT.

Explosion 9 Test Not Applicable. Lightning Direct Effects 23 Tested Per Category “X”.

Waterproofness 10 Equipment Identified as “X”.

No Test Required. Icing 24 Tested Per Category “X”.