V

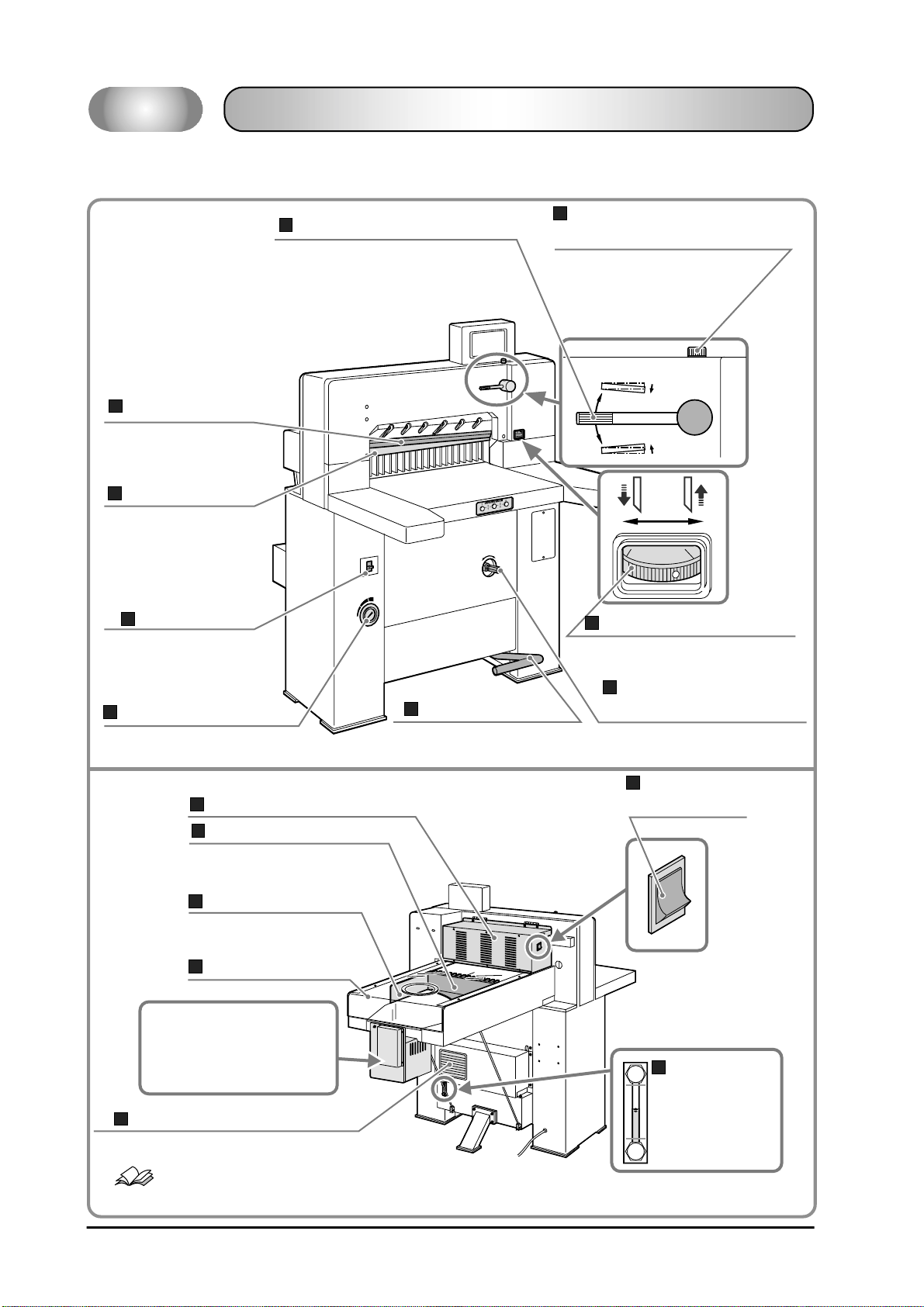

4. Operating Procedures ...............................................31

4-1 Cutting Operation on the Cutting Line ................................................... 31

4-2 Cutting Operation by Entering a Value................................................... 33

4-3 Creating a Cutting Program .................................................................... 35

4-3-1 Entering the Values to Create a Program .............................................35

4-3-2 Cutting the Sheets to Create a Program ................................................39

4-3-3 Copying a Program ...............................................................................42

4-3-4 Inserting a Step .....................................................................................44

4-3-5 Deleting a Step ......................................................................................45

4-3-6 Deleting a Program ...............................................................................46

4-3-7 Even Divide Cutting Program ..............................................................47

4-3-8 Total Cutting Program ..........................................................................50

4-4 Using a Cutting Program......................................................................... 53

4-5 Compression Operation........................................................................... 54

4-6 Clamp Support Plate ............................................................................... 55

4-7 Changing the Push-out Length ................................................................ 57

5. Troubleshooting.........................................................59

5-1 The Bottom Sheet Is Longer Than the Top Sheet................................... 59

5-2 There Is a Scratched Line On the Cutting Face ...................................... 59

5-3 The Sheets Are Not Cut Parallel ............................................................. 60

5-4 The Top Sheet Is Marked By the Clamp................................................. 60

5-5 The Sheets Are Contaminated With Grease ........................................... 60

5-6 A Sheet Remains Partly Uncut................................................................ 61

5-7 Some Sheets Remain Uncut .................................................................... 61

5-8 Some Sheets Are Bent Down .................................................................. 61

5-9 An Error Code Appears........................................................................... 62

6. Maintenance ...............................................................63

6-1 Cutting Stick Replacement...................................................................... 63

6-2 Knife Replacement .................................................................................. 64

6-2-1 Precautions for Knife Replacement ......................................................64

6-2-2 Outline and Notes on Knife Replacement ............................................65

6-2-3 Removing the Knife ..............................................................................66

6-2-4 Installing the Knife ...............................................................................69

6-3 Knife Angle and Cutting Depth Adjustments ......................................... 72

6-4 Clamp Pressure Adjustment .................................................................... 74

6-5 Backgauge Home Position Calibration ................................................... 75

6-6 Backgauge Angle Adjustment ................................................................ 76

6-7 Backgauge Parallel Adjustment .............................................................. 77

6-8 Lubrication .............................................................................................. 78

6-9 Oil Replacement...................................................................................... 79

6-10 Cleaning the Cooling Fan ....................................................................... 80