5

Contents

I Introduction ....................................................................................................... 1

II Symbols used in this manual ........................................................................... 2

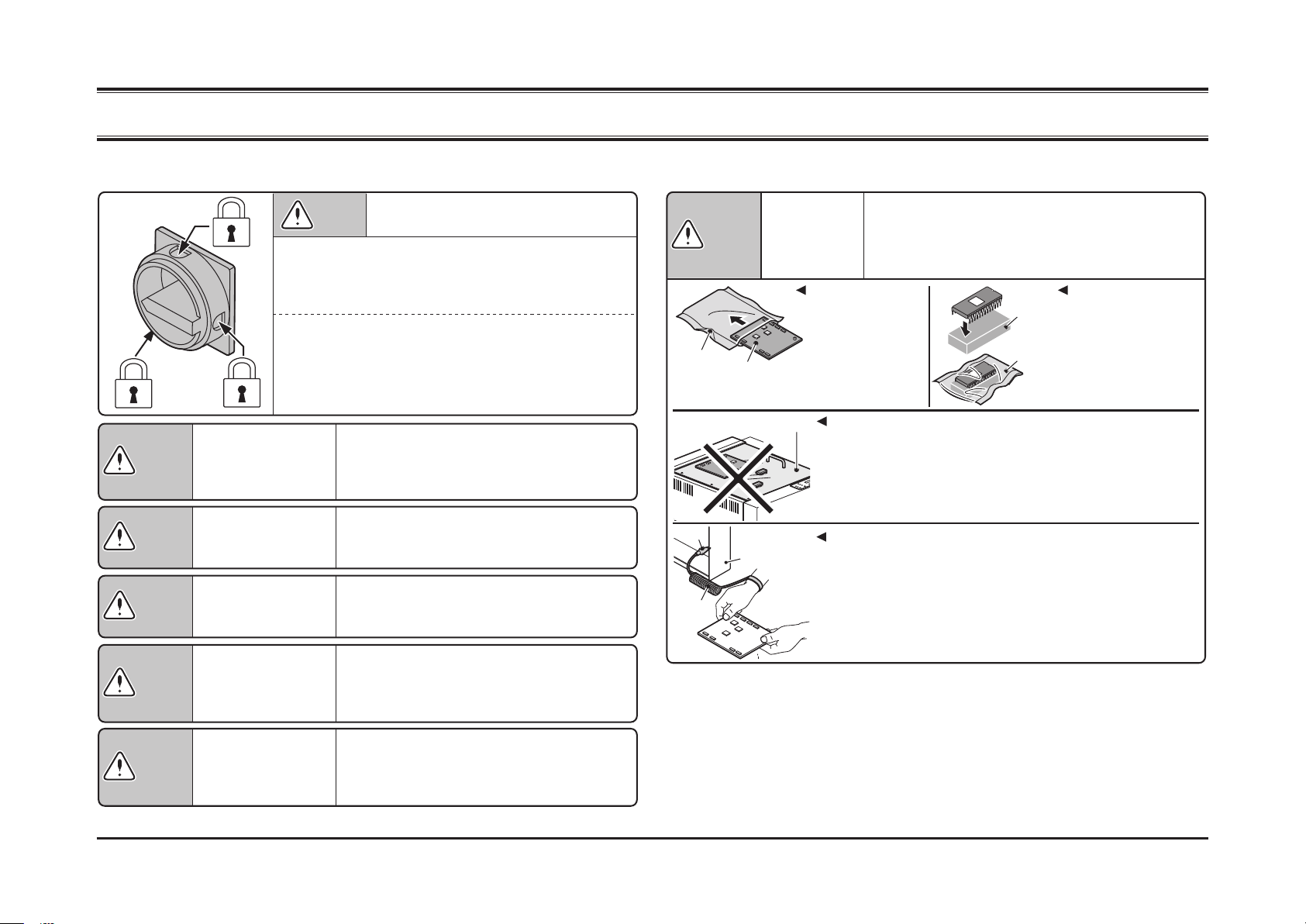

III Cautions when undertaking service operations - Part 1 ................................. 3

IV Cautions when undertaking service operations - Part 2 ................................. 4

1 General .............................................................................. 7

1 - 1 Differences from the PC-P43 .................................................................... 8

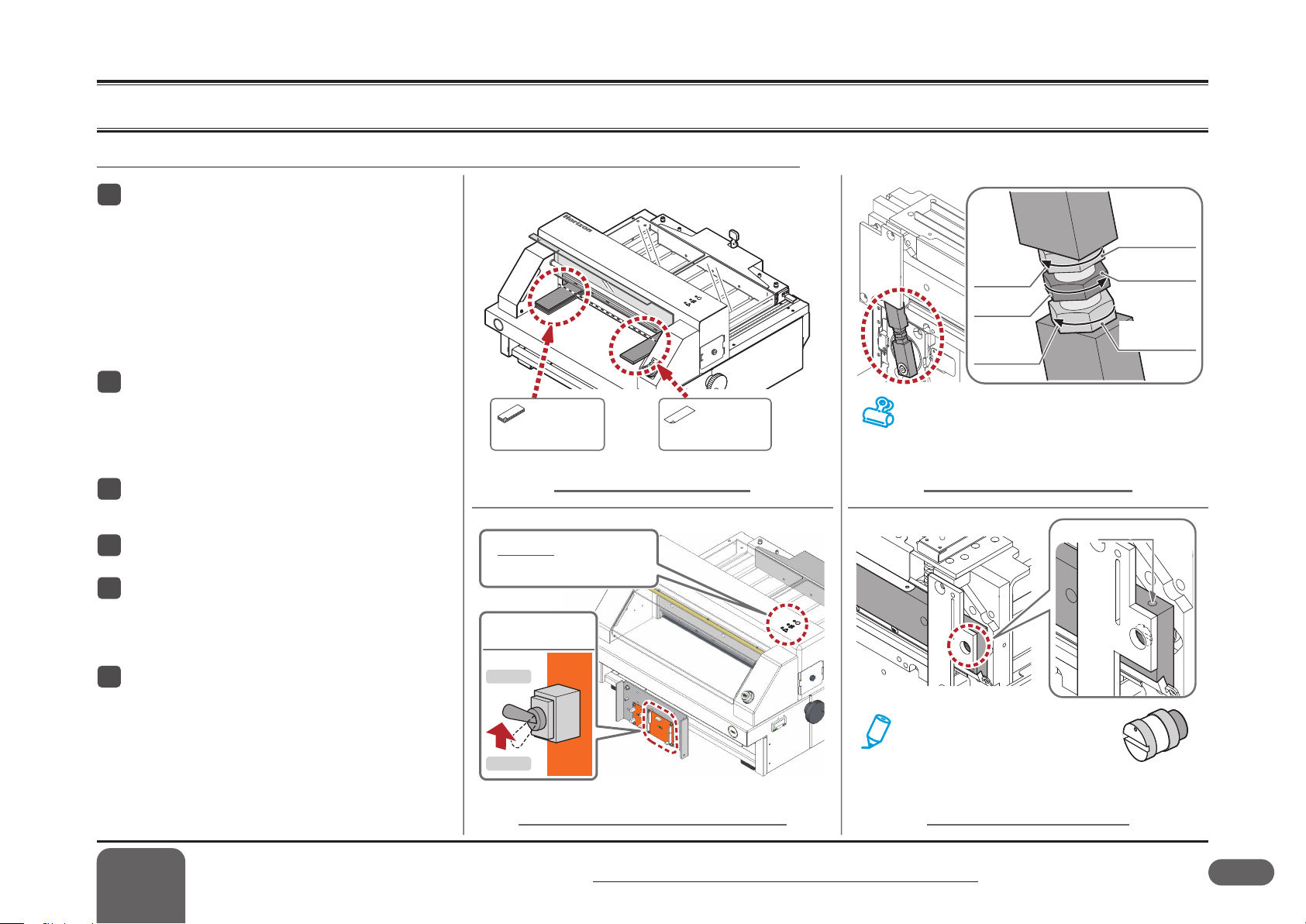

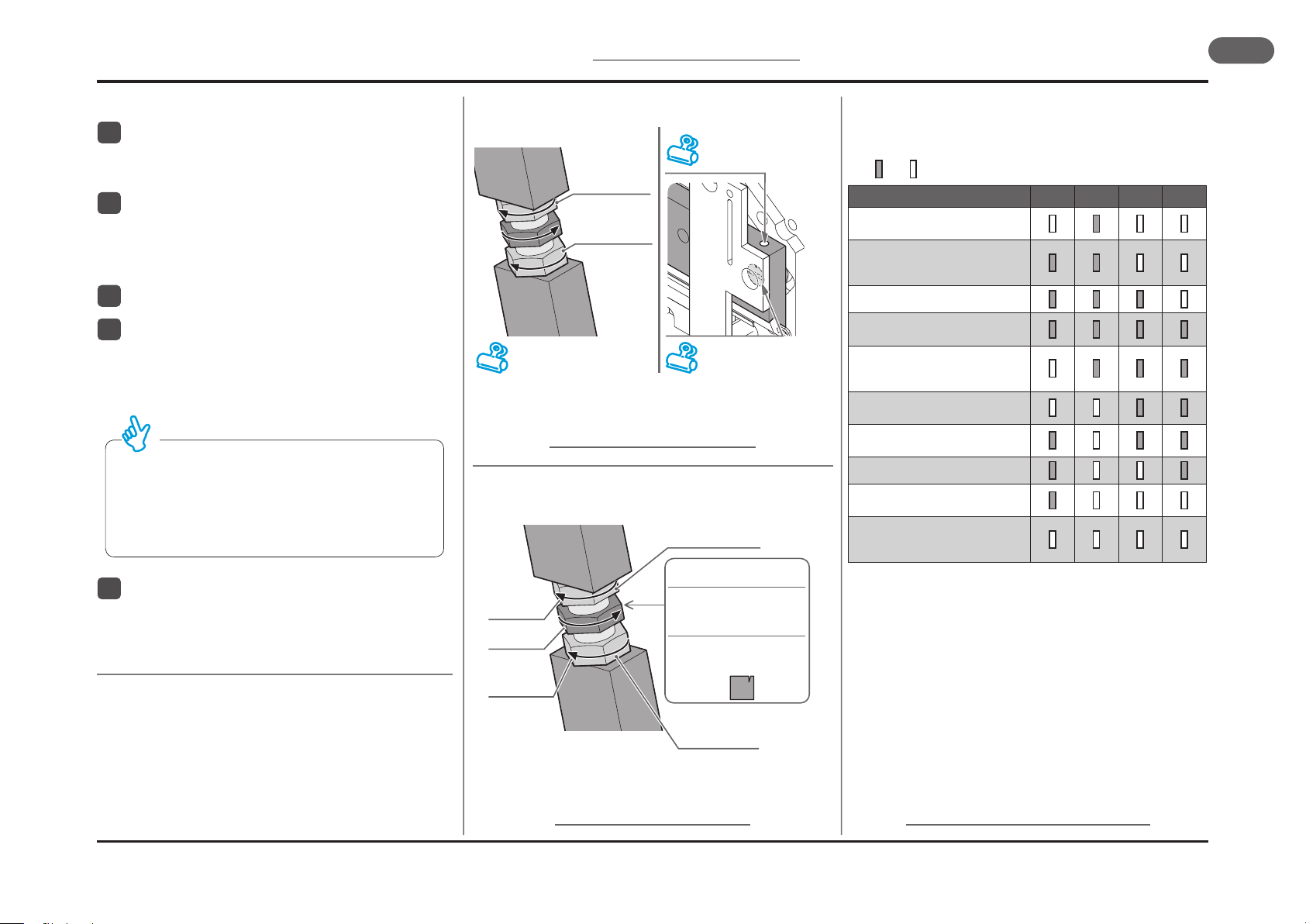

1 - 2 Adjusting the Angle and the Height of the Knife ........................................ 9

1 - 3 Machine Safety Features ........................................................................ 11

2 Troubleshooting ............................................................... 15

2 - 1 System Errors ......................................................................................... 16

2 - 2 Monitor LEDs Do Not Light ..................................................................... 19

2 - 3 The Machine Does Not Start by Pressing the Cutting Buttons ............... 20

2 - 4 The Machine Stops (System error 8 or 9) ............................................... 21

2 - 5 The Machine Stops Without a Beeping Sound ....................................... 22

2 - 6 The Last Few Sheets Are Left Uncut ...................................................... 23

2 - 7 Cut Size Is Not Accurate ......................................................................... 24

2 - 8 Skew Cut ................................................................................................. 25

2 - 9 The Book Spine Is Crashed / The Book Is Contaminated ....................... 26

2 - 10 Vague Cut Line ..................................................................................... 27

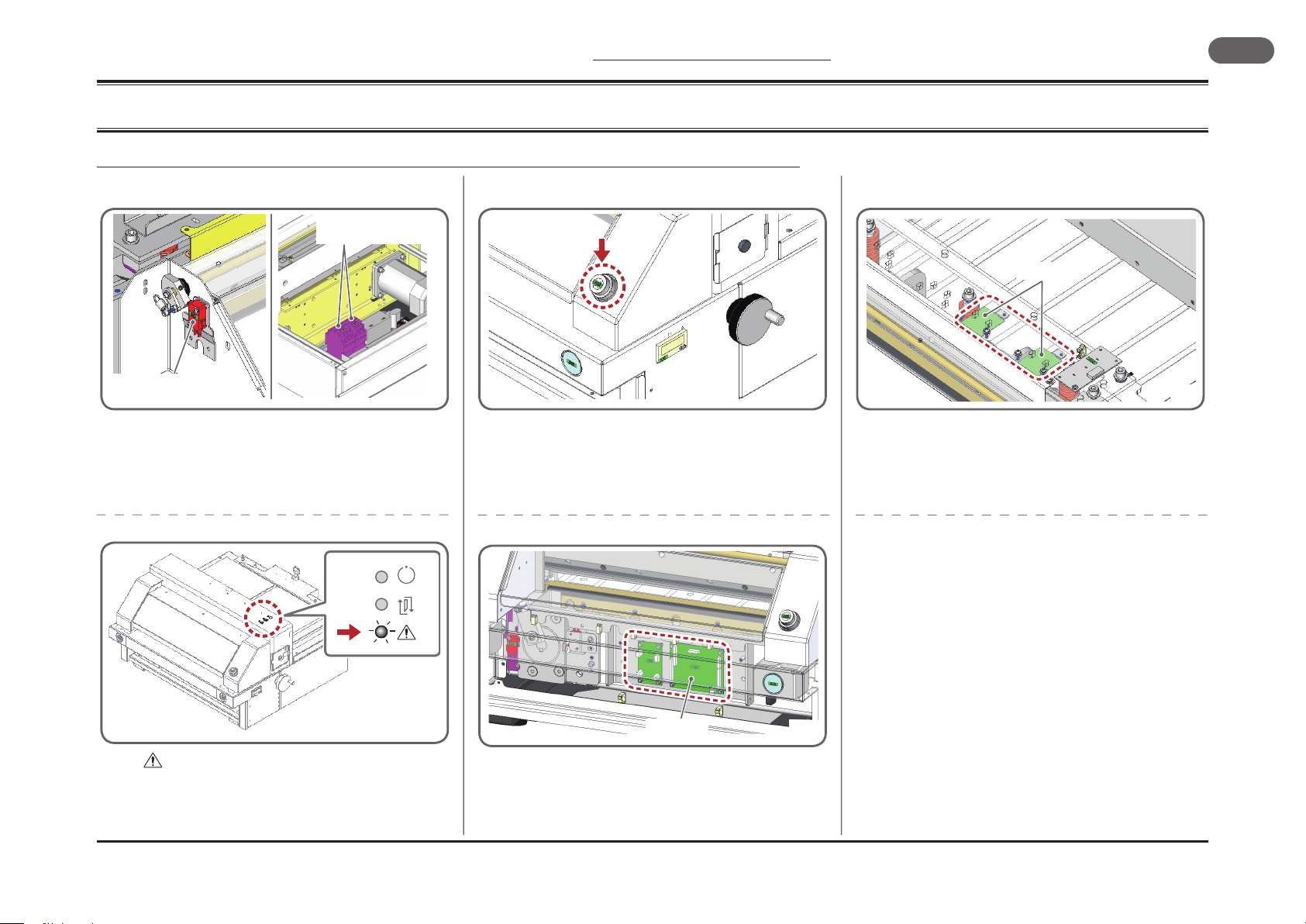

3 Descriptions of Mechanisms............................................ 31

3 - 1 Cutting and Clamp Section ..................................................................... 32

3 - 2 Backgauge Section ................................................................................. 33

3 - 3 Safety Cover Section .............................................................................. 34

3 - 4 Removing the Back Table ...........................................................................35

3 - 5 Removing the Front Table ...........................................................................36

3 - 6 Removing the Clamp ...................................................................................38

3 - 7 Removing the Knife Holder .........................................................................39

3 - 8 Removing the Cam .....................................................................................40

3 - 9 Removing the Backgauge Drive Section .....................................................41

3 - 10 Removing the Motor ..................................................................................42

3 - 11 Replacing the Knife ...................................................................................43

4 Electrical Parts Location .....................................................51

4 - 1 PC-P430 Electrical Parts List ......................................................................52

4 - 2 Motor and Switch Locations and Names .....................................................54

4 - 3 Other Electrical Parts Locations and Names ..............................................55

5 Circuit Boards .....................................................................59

5 - 1 Board Locations and Names .......................................................................60

5 - 2 QPW-968 (P115811) Control Board ...........................................................61

5 - 2 - 1 QPW-968 Board Diagram ...................................................................................... 61

5 - 2 - 2 QPW-968 LED Location ......................................................................................... 62

5 - 3 QPW-959 (P114711) Cut Line LED Current Control Board ........................63

5 - 4 QPW-969 (P115911) LED Board ................................................................64

5 - 11 ROM Version History ................................................................................65

6 Electrical Circuits ................................................................69

6 - 1 SD Circuit ....................................................................................................70

6 - 1 - 1 SD1 AC Power Circuit ............................................................................................ 70

6 - 1 - 2 SD2 Input and Output System Circuit .................................................................... 71

END SHEET ...............................................................................................74