4

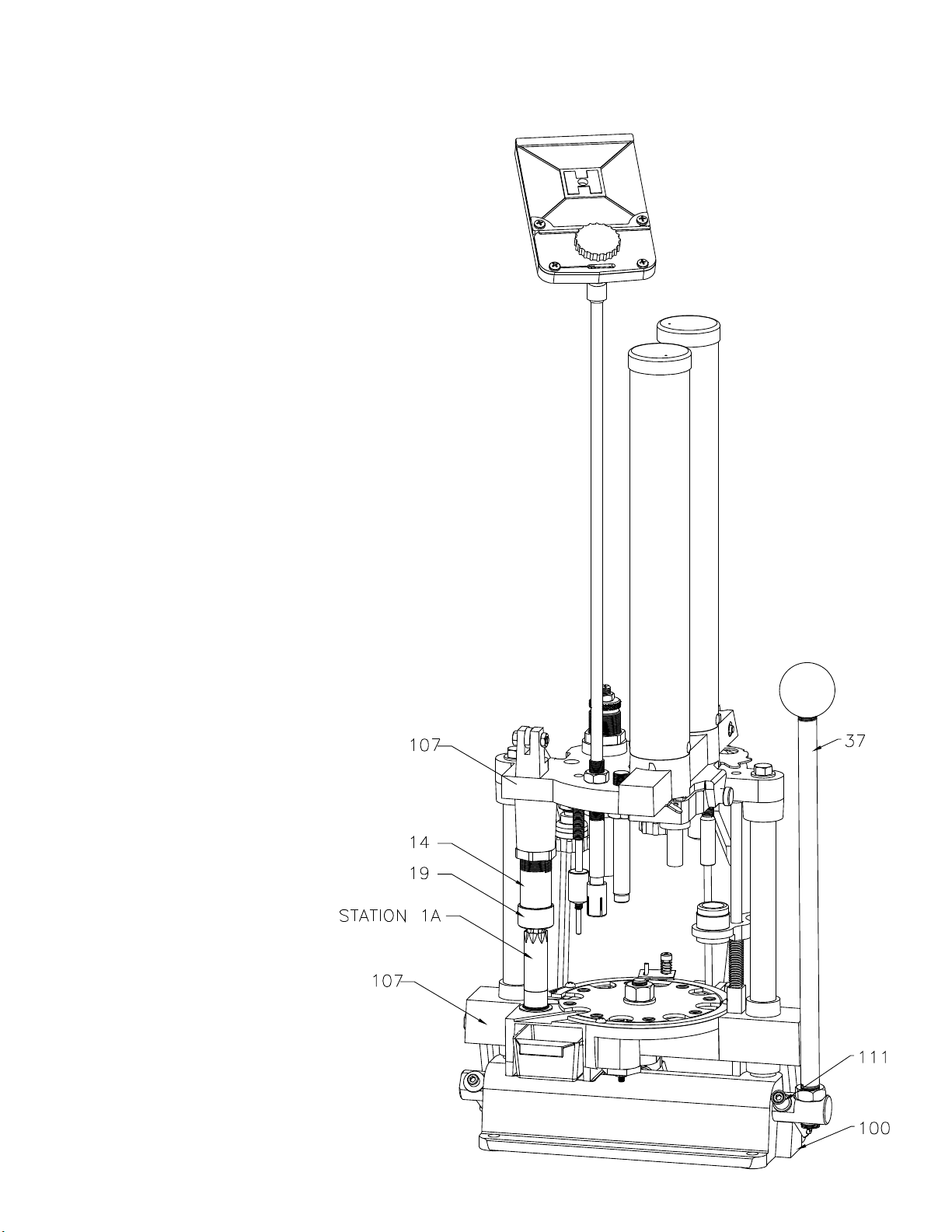

SETTING UP YOUR 366 AUTO

Mount your 366 Auto securely toward the front of a sturdy

bench. All operations of the press are to a full stop, so the

operating handle must clear the bench when in the down

position. Since the shells are ejected down a chute, out the

back of the loader, you may want to set your loader up on riser

blocks (010060) to provide access to the completed shells. An

alternate method to catch finished shells would be to cut a hole

in the bench and place a box underneath.

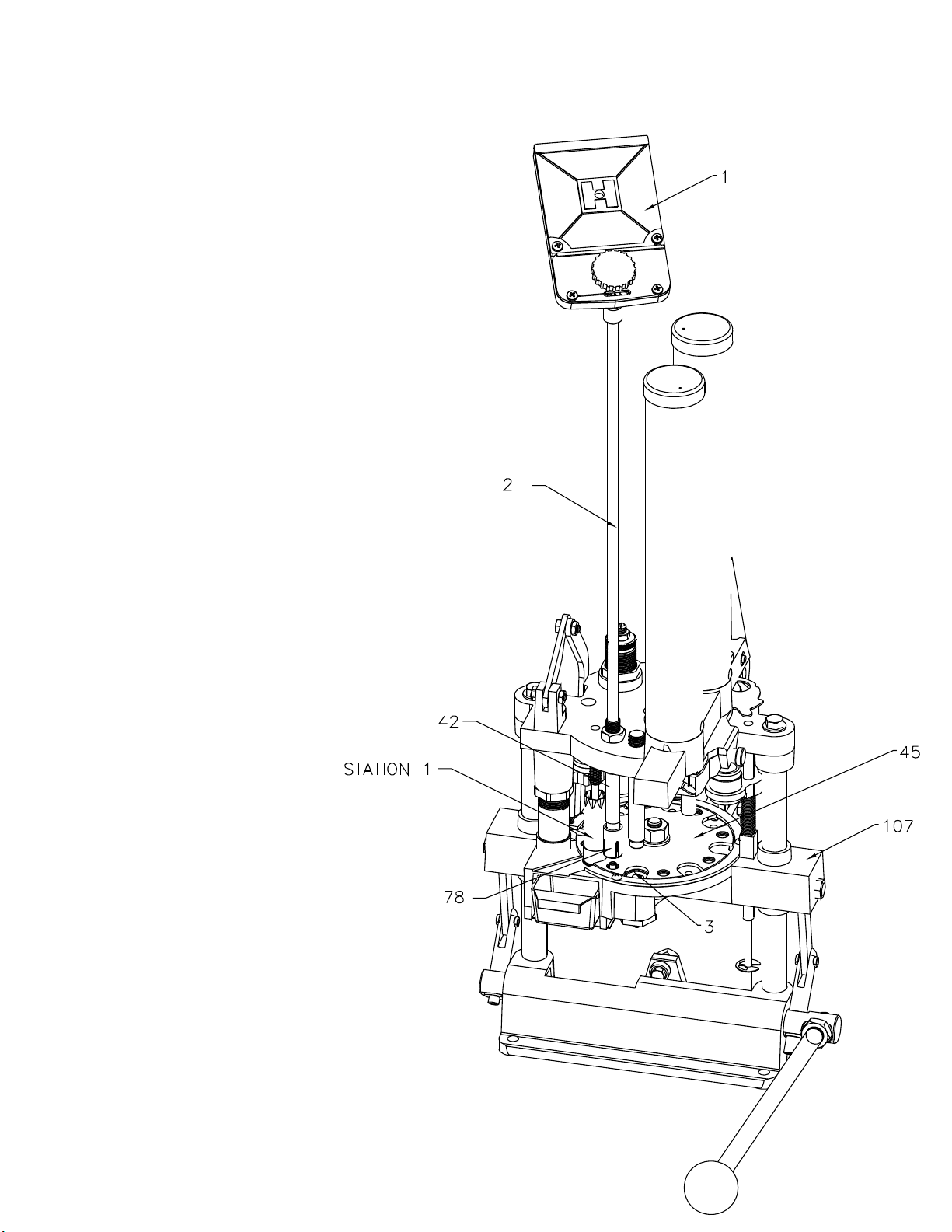

1. Before filling the shot and powder hoppers, turn the

measure assembly upside down and carefully push the

charge bar out and check the powder and shot bushing

numbers.

2. Your loader was furnished with standard bushings,

12 GA. 11⁄8oz. #7 ½ shot, 468 Powder Bushing; 20 GA.

7⁄8oz. #9 shot, 393 Powder Bushing; 28 GA. ¾ oz.

#9 shot, 303 Powder Bushing; 410 GA. ½ oz. #9 shot,

291 Powder Bushing but double check to insure you

will dispense the correct weight of powder and shot.

3. While the charge bar is removed or pushed back,

check that the measure casting seals (rubber washers)

are in the recess in the measure casting.

4. Reinstall the bushings and push the charge bar back

in place. If the powder slide should drop out of the

measure assembly, do not disassemble the measure

plate.

5. Replace the powder slide by pressing it in from the side

against the detent spring, pull spring back and fit into

slot.

6. Reinstall the measure assembly by tilting the casting

as you slip the measure plate and shot rotor spring

under the hold down washer, and the charge bar into

the slot of the charge bar cam.

7. Secure assembly in position with measure attaching

bolt.

8. Install the primer tube in the die head casting and fill

the primer tray according to instructions furnished

with it. Do not fill the tube at this time.

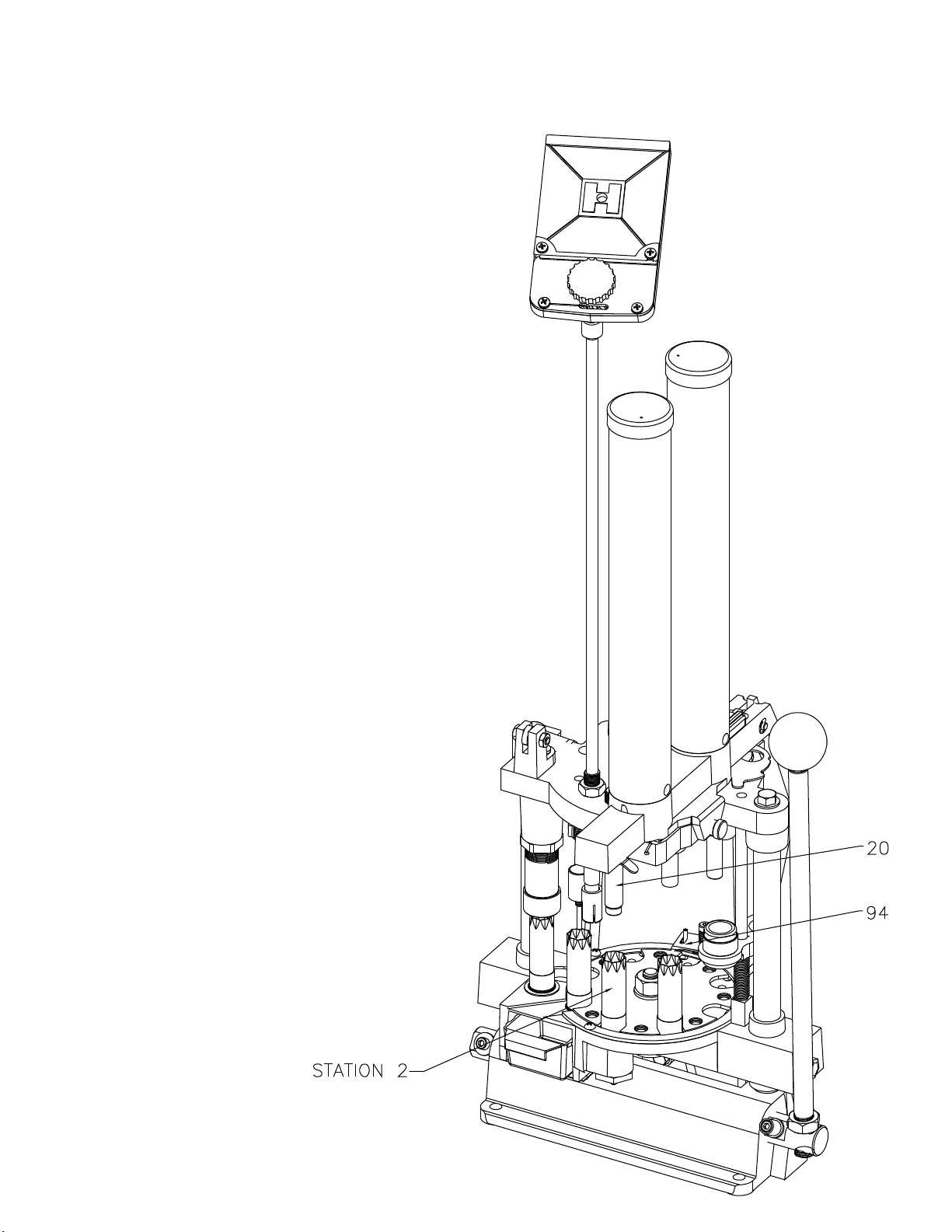

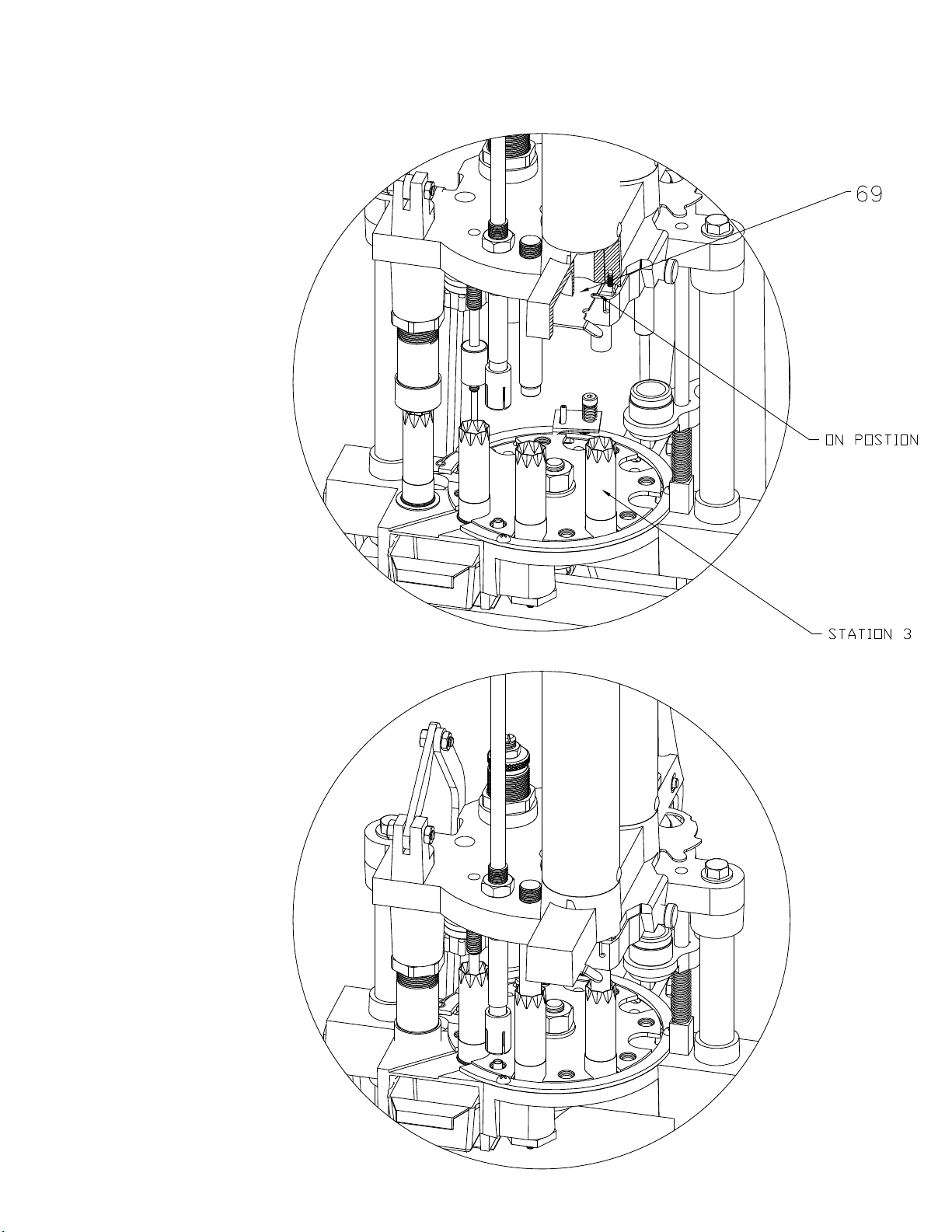

9. Check the individual stations of the loader for

alignment to make sure nothing has loosened during

shipping. Shut off the powder slide (push in) and the

shot rotor (pull forward) while checking each station.

READ THIS SECTION BEFORE ATTEMPTING TO LOAD AMMUNITION!