MAN1175-01-EN

Indianapolis, USA | Cork, Ireland | Calgary, Canada | Bangalore, India | Oakleigh, Australia | Tianjin, China | Esteio, Brazil

Please visit our website for a complete listing and to learn more about certified Horner Automation products.

This document is the property of Horner Automation Group, and is subject to change.

page 5 of 8

4 CSCAPE CONFIGURATION

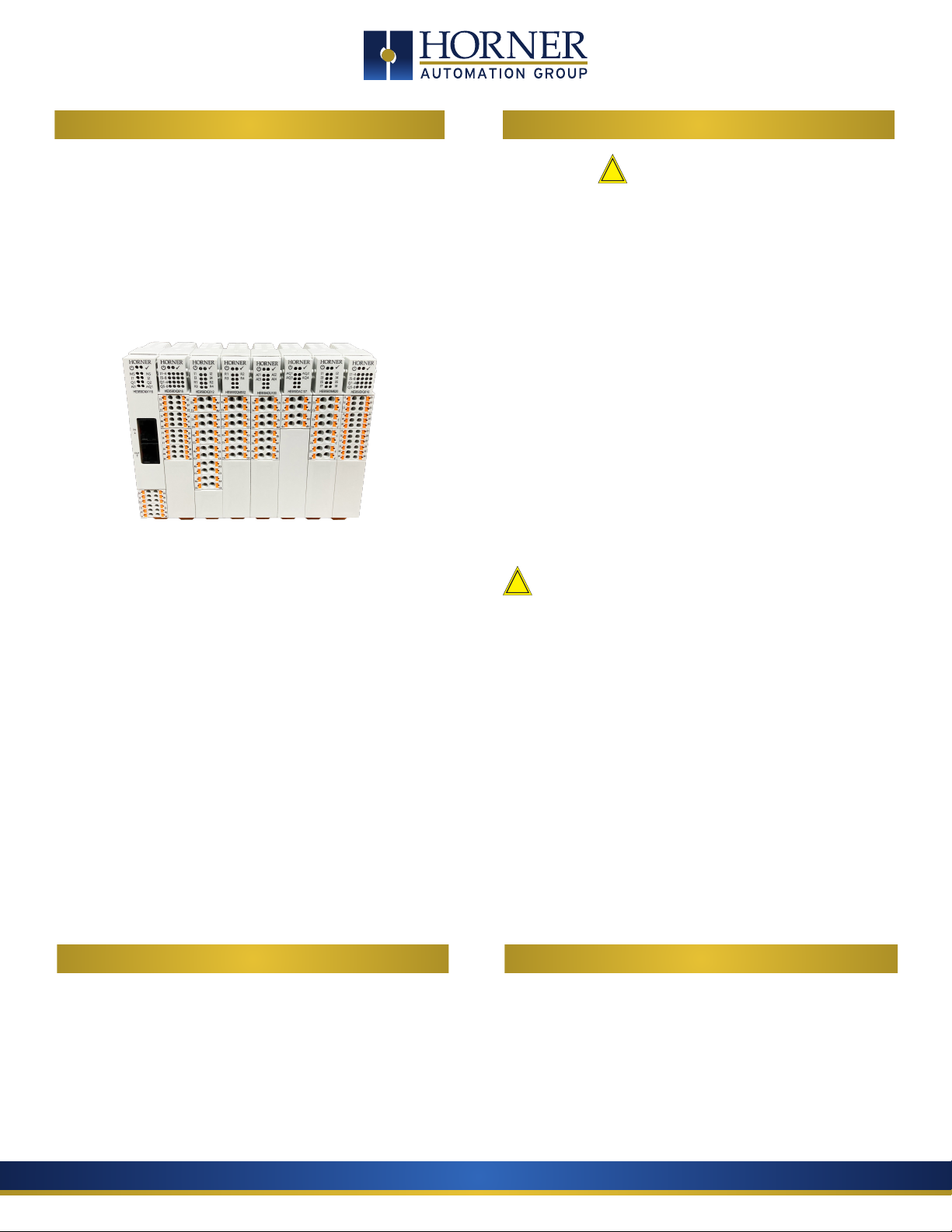

The HE959CNX116 Base is configured from Cscape, under “Hard-

ware Configuration”. Cscape 9.9 (SP8 or later) is required. OCS

firmware must be updated to support OCS-I/O. Please check the

release notes on your OCS model to ensure OCS-I/O support is

included.

General configuration procedure:

1. In Cscape, select Controller > Hardware Configuration.

2. Make sure the OCS controller to be used in the application

has been properly selected.

3. Select the “CsCAN I/O” Tab.

4. Click the “Add” Button

5. Select “HE959CNX116” in the OCS-I/O tab

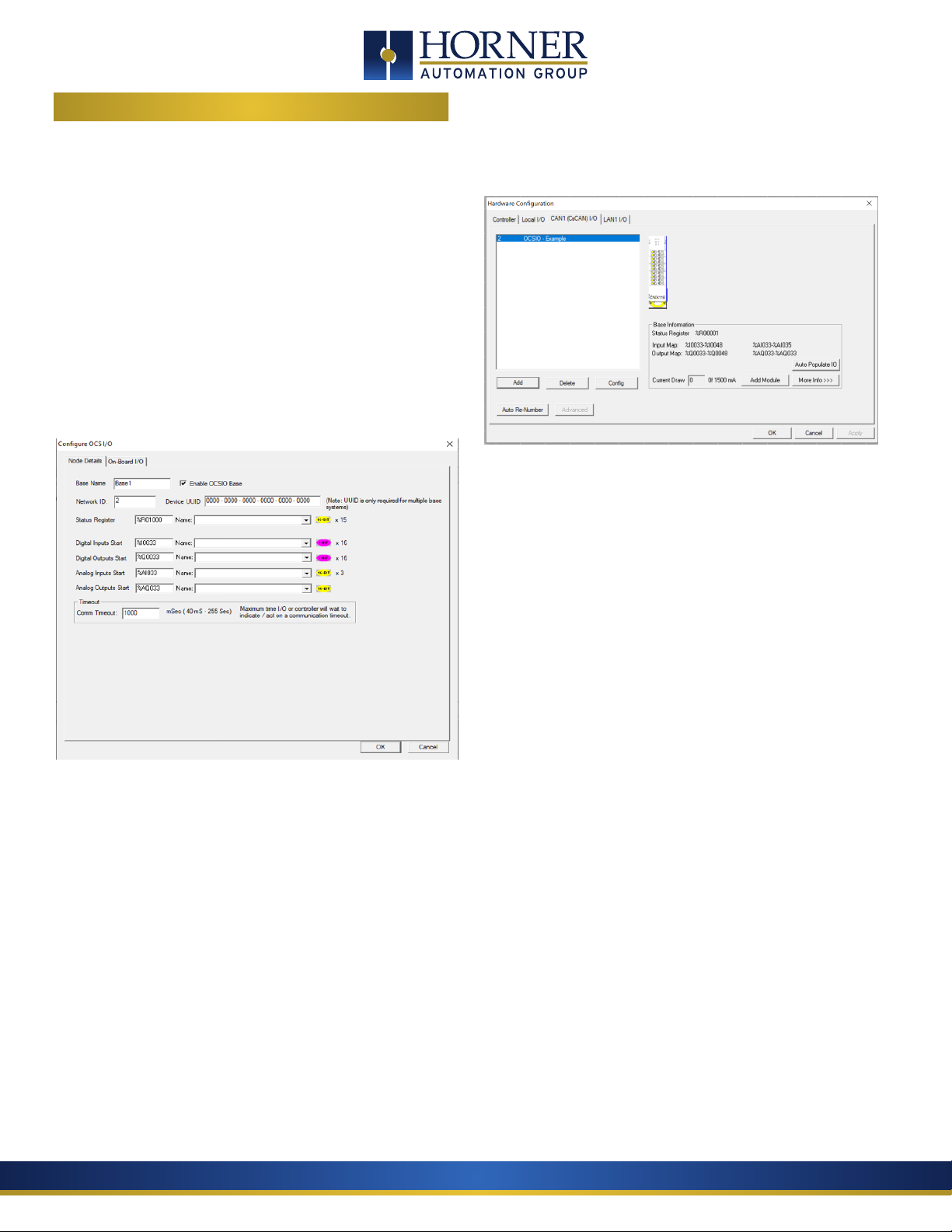

6. Click the “OK” button. This opens the following dialog:

• Base Name – any descriptive text (up to 15 characters)

• Enable OCSIO - When this option is checked Input/Output

data from the host controller will get transmitted to OCSIO.

If the option is unchecked Input /Output data will NOT get

transmitted to OCSIO but communication between the Host

controller and OCSIO will be healthy

• Network ID – unique CsCAN ID (1-79 decimal)

• Device UUID - Each OCSIO base requires a Unique ID to

establish communication with the host controller. In case

of Single Base OCSIO entering UUID is not required, host

controller can automatically assign that. In case of Multiple

base configurations, it is Mandatory to enter UUID of each

base.

• Status Register – Location where fifteen consecutive words

are reported

• Digital Inputs / Digital Outputs / Analog Inputs / Analog

Outputs Start – starting locations for each type of I/O for

this base. Be careful to choose starting addresses that do

not conflict with OCS built-in I/O mapping.

• Comm Timeout – Maximum amount of time the

HE959CNX116 will wait to act on a communications timeout

(40 to 255000ms)

7. After entering all the required information (above), click “OK”.

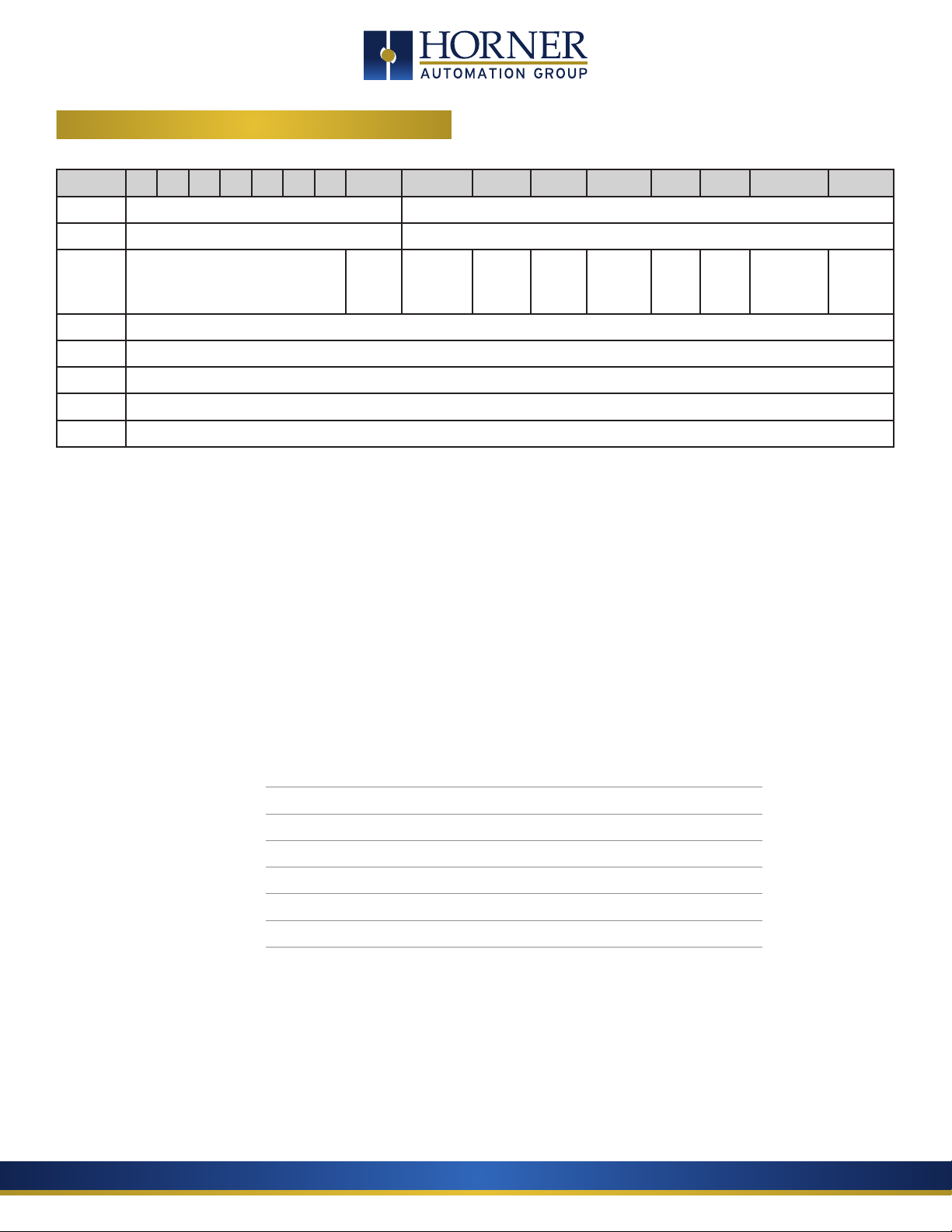

At this point, the following Hardware Configuration dialog will

appear:

8. Now modules can be added via the “Add Module” button. As

I/O modules are added the Input Map, Output Map, and Current

Draw are updated, showing the accumulated I/O Module Informa-

tion. More details regarding each module can be viewed via the

“More Info” button.

9. If the OCS-I/O base and I/O modules are properly connected

and powered up, and if Cscape currently has communications to

the OCS, the “Auto Populate IO” button may be used to recognize

all modules installed on this OCS-I/O base.

10. Right clicking on an I/O module will allow detailed configura-

tion to be performed, as follows:

a. Digital Input modules can be configured to update

on a change of state (typical) or periodically (rare). Input

filtering can also be adjusted from the default of 1mS.

b. Digital Output modules can optionally be configured

to hold last state in Stop/Idle mode.

c. Analog Input modules can be configured with an

update rate of 10mS to 255 seconds. Analog Inputs also

have configurable data type and range which varies by

module type.

d. Analog Output modules have configurable type and

range, and also can have Stop/Idle behavior adjusted to

Hold Last State, or go to Minimum (default), Medium or

Maximum value.

11. Press “OK” to complete the process.