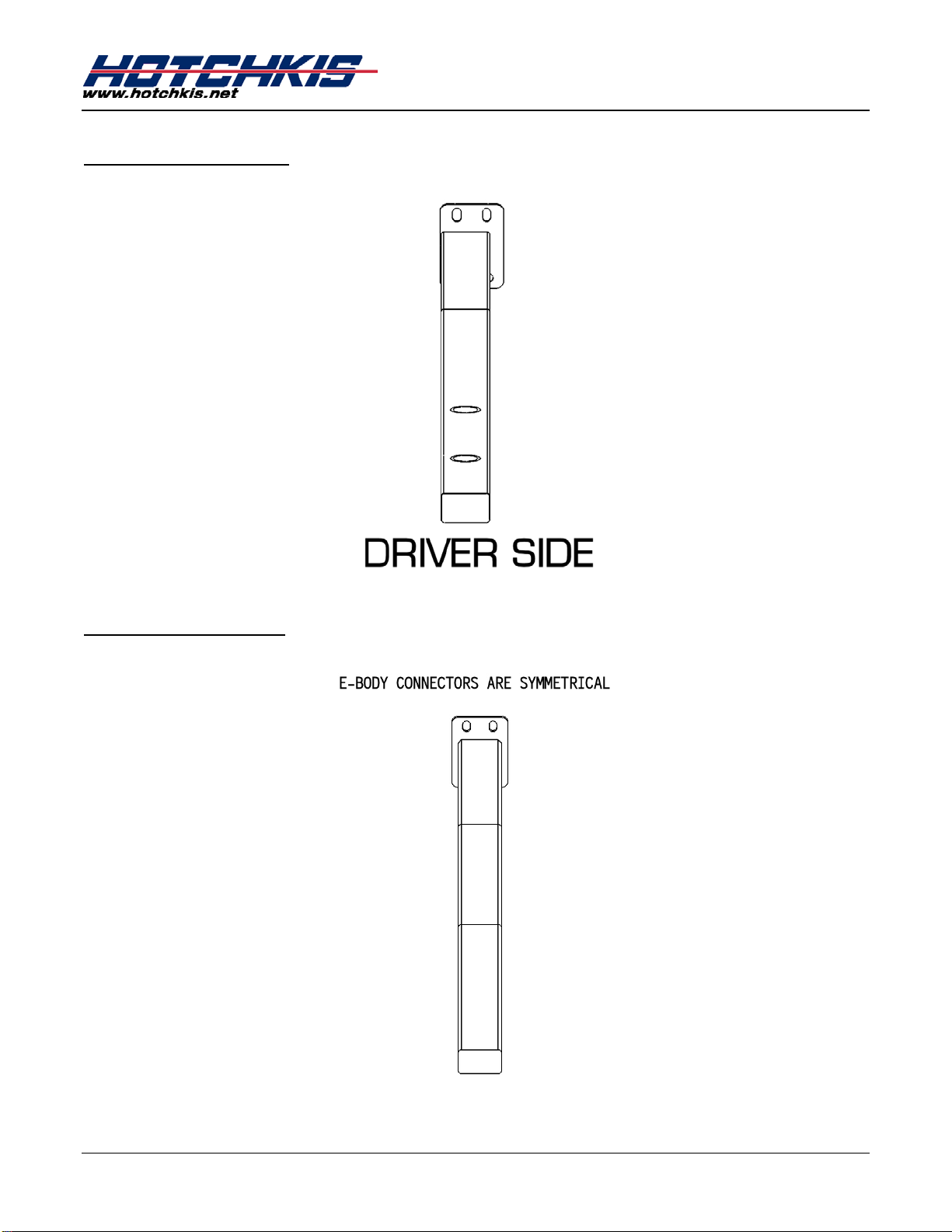

4010 & 4011S/L

Hotchkis Performance LLC. 1

Please read the following key points before installing this kit.

1 – Before performing the subframe connector installation, the vehicle must be completely assembled

with all body and component parts installed (e.g. fenders, hood, quarterpanels, trunk, full interior,

engine, glass, etc.). Basically, the subframe connectors should be one of the last components

installed on your vehicle. Reason being is you want the vehicle settled with all of it’s own final

weight. The car’s body is always in constant tension, with forces pushing or pulling within the

chassis & body. You want to make sure these forces don’t change after you install the subframe

connectors. For example, if you installed subframe connectors before installing the engine and

body panels this may result in having misaligned fenders, door panels and/or hood later on. The

car must be in it’s final state before the subframe connectors are installed.

2 – The subframe connectors must be installed on an alignment rack or floor ramps (all 4 wheels). The

vehicle must be sitting on it’s wheels at ride height in order to install the subframe connectors. Do

not use a two-post lift, as this will load the chassis/body in the wrong points causing the chassis to

tweak.

3 – If you your vehicle is equipped with torque boxes, please pay attention to step 3b of this manual.

You may be required to purchase extra hardware in this case.