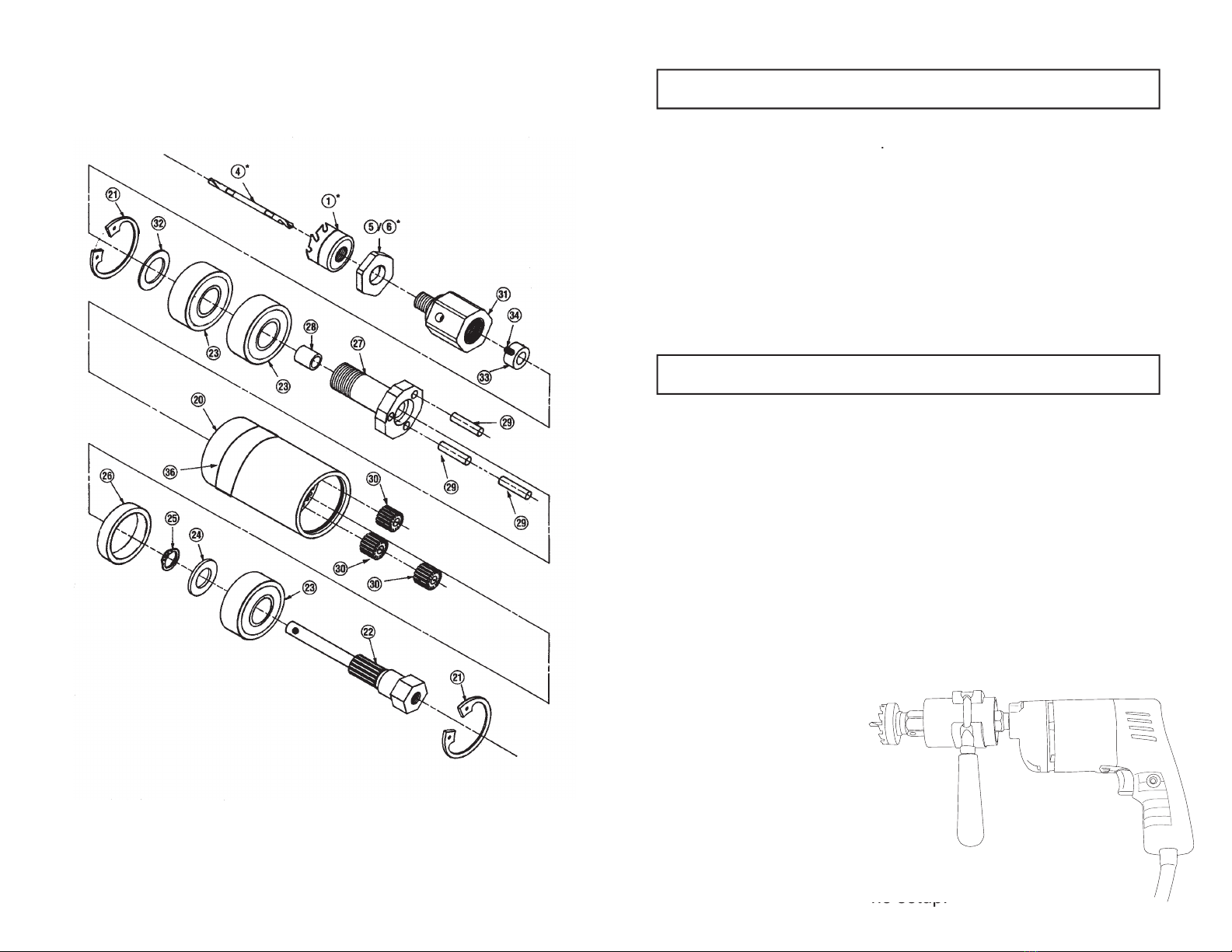

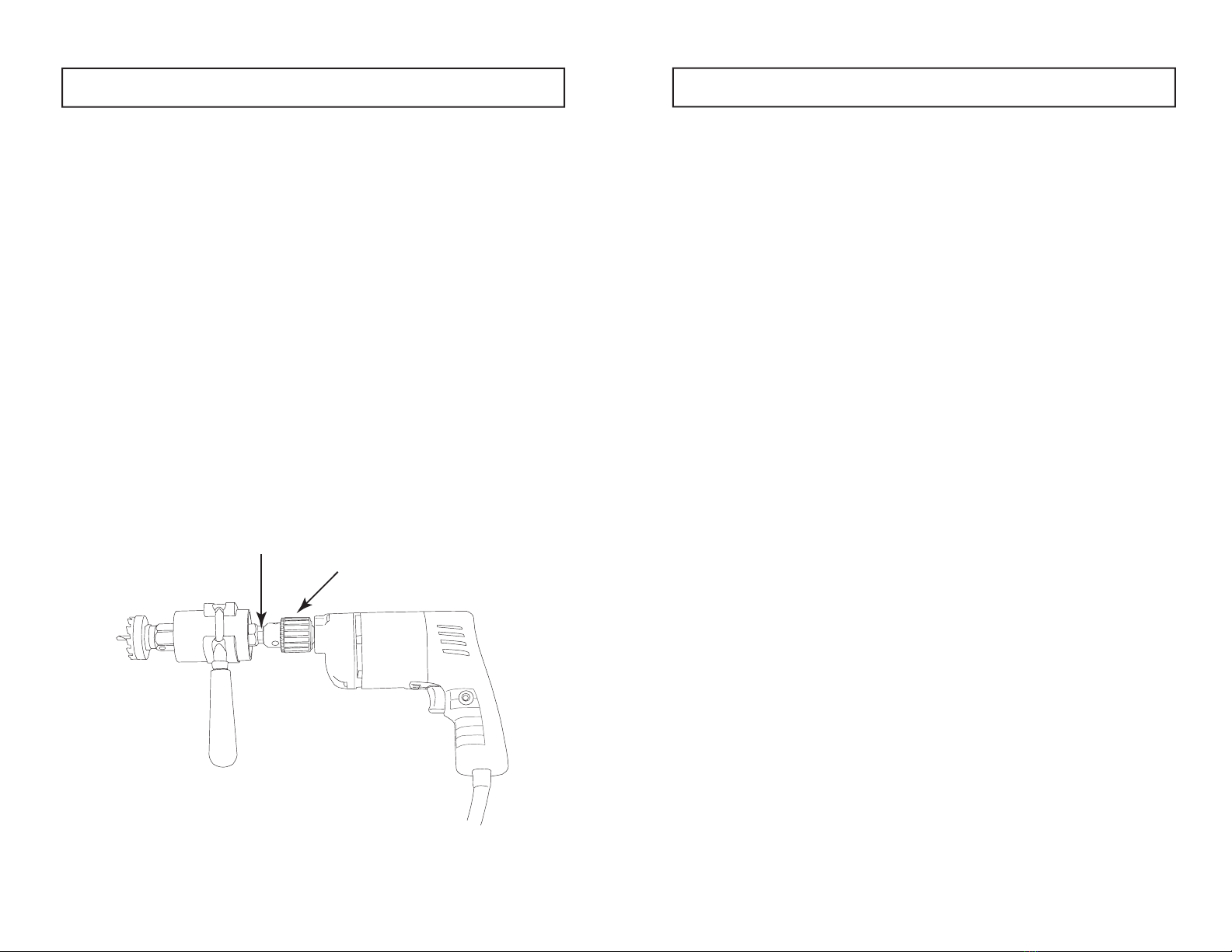

SPEED REDUCER

For reducing RPMs while maintaining

torque when using Holcutters

Hougen Manufacturing, Incorporated warrants its Portable Magnetic Drills, Electro-

Hydraulic Hole Punchers, and Tornado II Paint Shaker for a period of one (1) year

and other products for ninety (90) days from date of purchase against defects due to

faulty material or workmanship and will repair or replace (at its option) without charge

any items returned. This warranty is void if the item has been damaged by accident

or unreasonable use, neglect, improper service, or other causes not arising out of de-

fects in material or workmanship. No other expressed warranty is given or authorized.

Hougen Manufacturing, Inc. disclaims any implied warranty of MERCHANTABILITY

or FITNESS for any period beyond the expressed warranty and shall not be liable for

incidental or consequential damages. Some states do not allow exclusions of inciden-

tal or consequential damages or limitation on how long an implied warranty lasts and,

if the law of such a state governs your purchase, the above exclusion and limitation

may not apply to you. This warranty gives you specifi c legal rights and you may also

have other rights which vary from state to state.

To obtain warranty service, return the item(s), transportation prepaid, to your nearest

Factory Authorized Warranty Repair Center or to Hougen Manufacturing, Inc., 3001

Hougen Drive, Swartz Creek, Michigan 48473.

Hougen Drills (Hougen Cutters) are warranted against manufacturing defects only.

Subject to Hougen Manufacturing inspection.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTY, EXPRESSED OR IM-

PLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

© 2004 Hougen Manufacturing, Inc.

This product is covered under the following U.S. patent: 5,607,266.

Photographs and Specifi cations shown are accurate in detail at time of printing.

Manufacturer reserves the right to make improvements and modifi cations without

prior notice. Hougen and the Hougen logo are proprietary trademarks of Hougen

Hougen Manufacturing, Inc.

P.O. Box 2005 • Flint, MI 48501-2005

3001 Hougen Drive • Swartz Creek, MI 48473

OMSR0404 Printed and Made in U.S.A.