4 216 974 / 02 5

Subject to modications

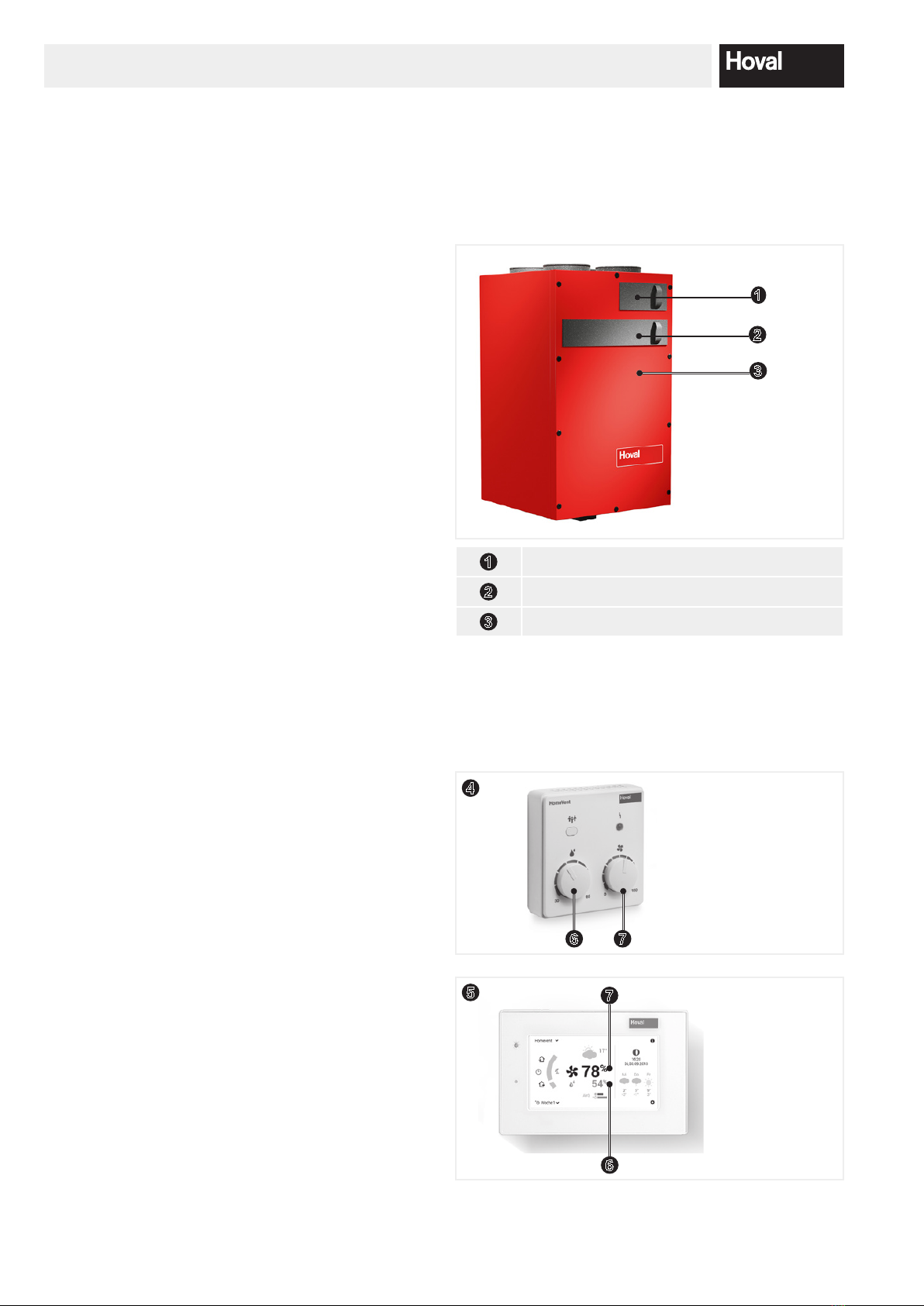

Standard operator terminal BG02 E

The operator terminal is suitable for on-wall mounting.

The target air volume and the maximum air humidity can

be set with two rotary knobs. With the party button, the

air volume can be increased for a limited period of time.

Connection to the HomeVent®comfort ventilation unit via

RJ45 plug connection. The unit can also be installed in a

secondary room.

TopTronic®E room control module comfort plus

The TopTronic®E room control module comfort plus is

available either with a black or white design.

Operable via colour touchscreen (4.3-inch). The connec-

tion to the HomeVent®comfort ventilation unit is made

via RJ45 plug connection or plug terminals (max.

0.75 mm2). The unit can be installed on the wall with an

on-wall mounted frame or with a wall-mounting plate and

ush-mounted boxes. The TopTronic®E room control

module carries out the following

functions:

• Operation of all Hoval units connected to the bus.

• Authorisation management for operation.

• Ecient control of the ventilation system by working

with day programmes.

• Selection between dierent start screens possible

during commissioning.

• Customer-specic congurable screen for displaying

the following elements: date, time, target air volume in

%, maximum target humidity in %, active day or week

programme, display of the current air quality inside

and outside the building based on a colour marking

(only in combination with VOC air quality sensors),

display of the current weather or weather forecast

(only possible in combination with TopTronic®online),

phases of the moon.

Control error:

If the unit control fails, the unit switches

o. The state is displayed on the operator

terminal. Contact the HomeVent specialist

near you.

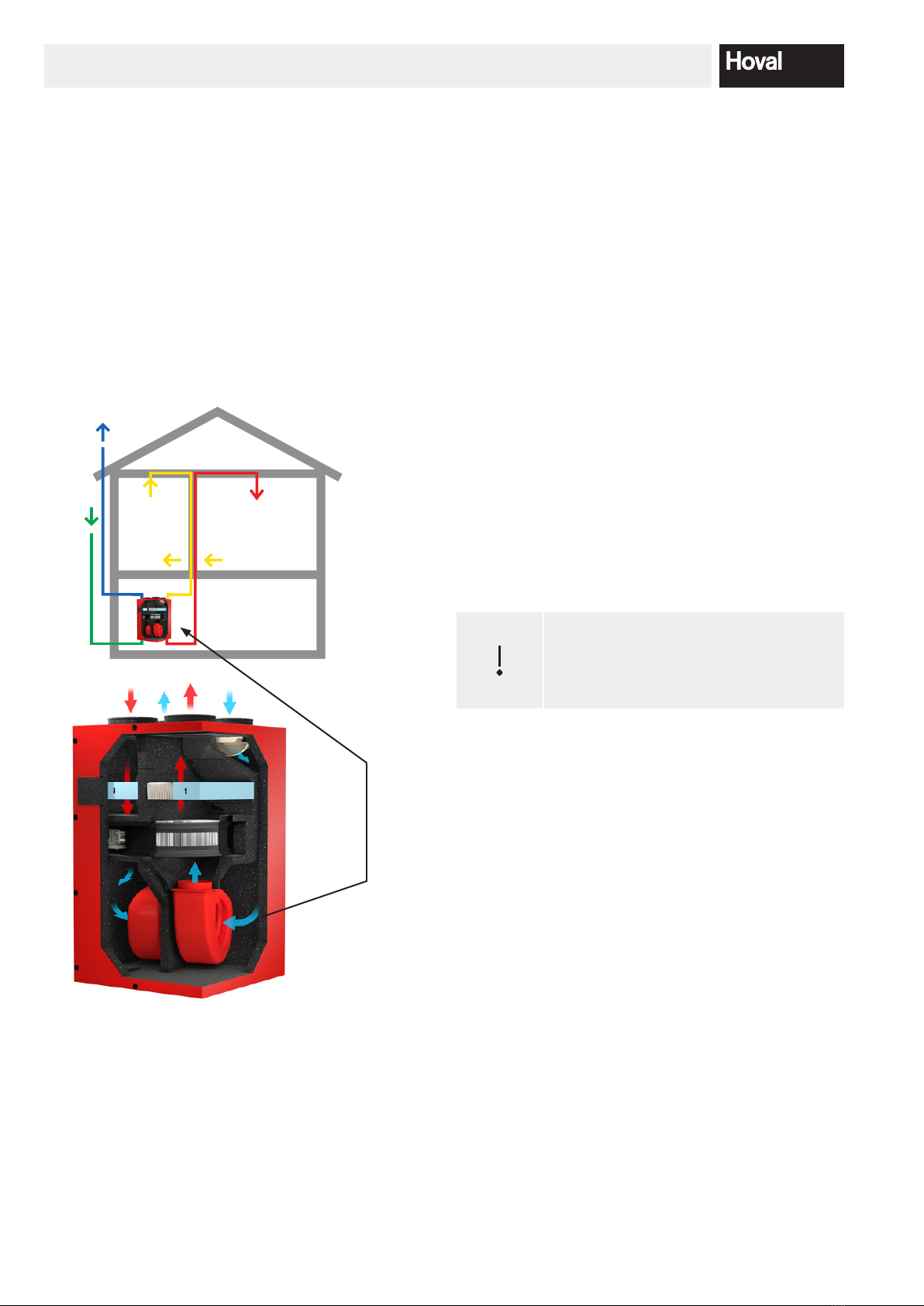

Air quality

Optionally, one or two VOC air quality sensors can be

installed in the unit during commissioning. In addition, an

activated carbon lter can be installed on the supply air

side as an option. The VOC air quality sensor(s) cont-

inuously monitor(s) the air for volatile organic compo-

nents and regulate the air volume that is supplied or ex-

tracted via the speed of the fans. This results in optimal

air quality in the building with minimal energy input.

VOC air quality sensor on extract air side: The extract

air is continuously monitored for odours, tobacco smoke,

cleansing agents, etc. If the concentration of the extract

air exceeds a certain value, the air volume is increased

correspondingly.

VOC air quality sensor on fresh and extract air side: The

extract and fresh air is continuously monitored for odours,

tobacco smoke, cleansing agents, etc. If the

TECHNICAL INFORMATION

concentration of extract air exceeds a certain value, the

air volume is increased correspondingly.

If the concentration in the fresh air exceeds a certain

value, the air volume is reduced correspondingly. The

sensor registering the higher value takes priority. The

sensitivity can be set to one of 3 stages. On the

TopTronic®E room control module comfort plus, the air

quality is displayed by a bar for the extract air and a bar

for the fresh air, which will either be green (good air),

orange (slightly contaminated air) or red (bad air).

The activated carbon lter can be inserted in place of

the standard supply air lter. This is a high-capacity lter

(ePM1.050%) with high eciency against particles (pol-

len, ne dust, etc.) and against gaseous pollutants and

odours (agriculture, trac, etc.).

Cooling

The warm fresh air can be cooled using the CoolVent®

option. However, this requires an air-conditioning system

to be present in order to provide the necessary cooling

in the room. The enthalpy recovery system extracts heat

from the warm fresh air and feeds it to the cold extract

air. The necessary output of the air-conditioning system

is thereby reduced. The eciency for this process is

85%. The CoolVent function is an option which must be

activated during commissioning.

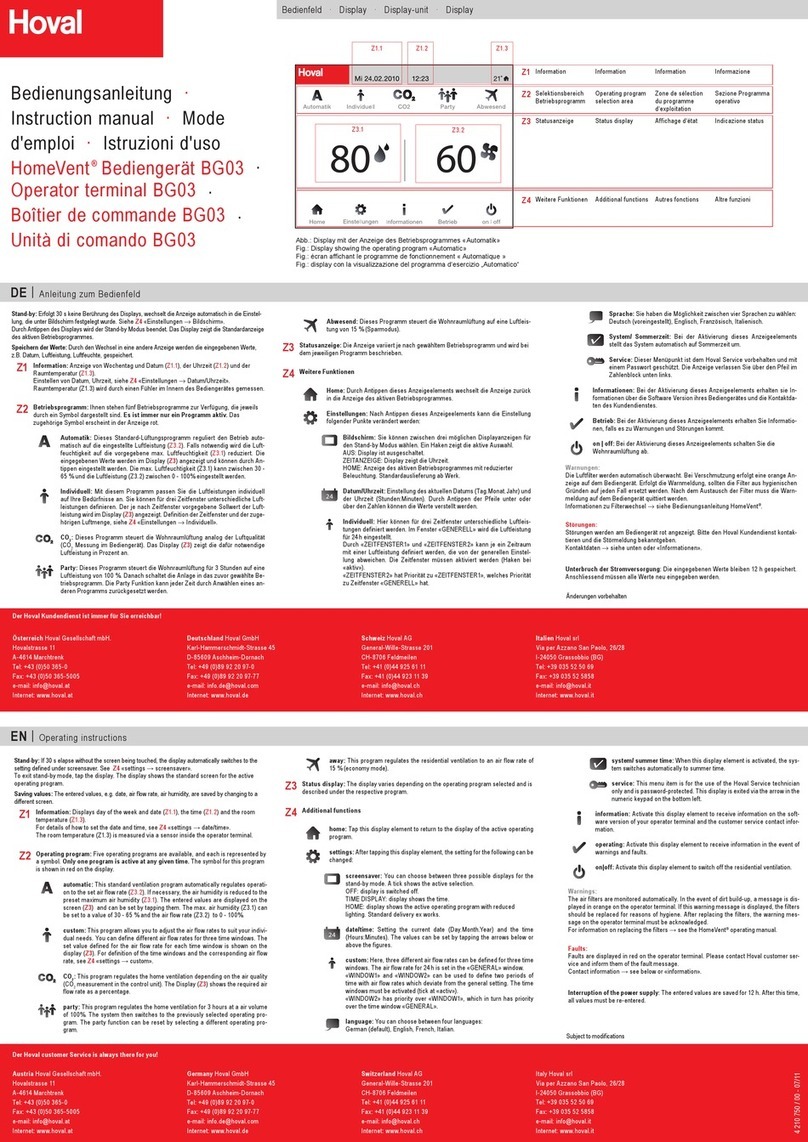

4.2 Use

Settings on the operator terminal

The operator terminal allows you to adjust your

HomeVent®comfort ventilation system to suit your

needs. Using the operator terminal or module, it is

possible to set the basic ow rate at which the

ventilation unit should always be operated as a

minimum. Furthermore, the target humidity value can be

selected. If this is exceeded in the room, the ow rate

of the ventilation unit is increased. Please bear in mind

that, especially during the change of seasons, setting a

low target humidity value can result in a high volumetric

current and thus noise. Detailed operating instructions

were enclosed with your operator termina

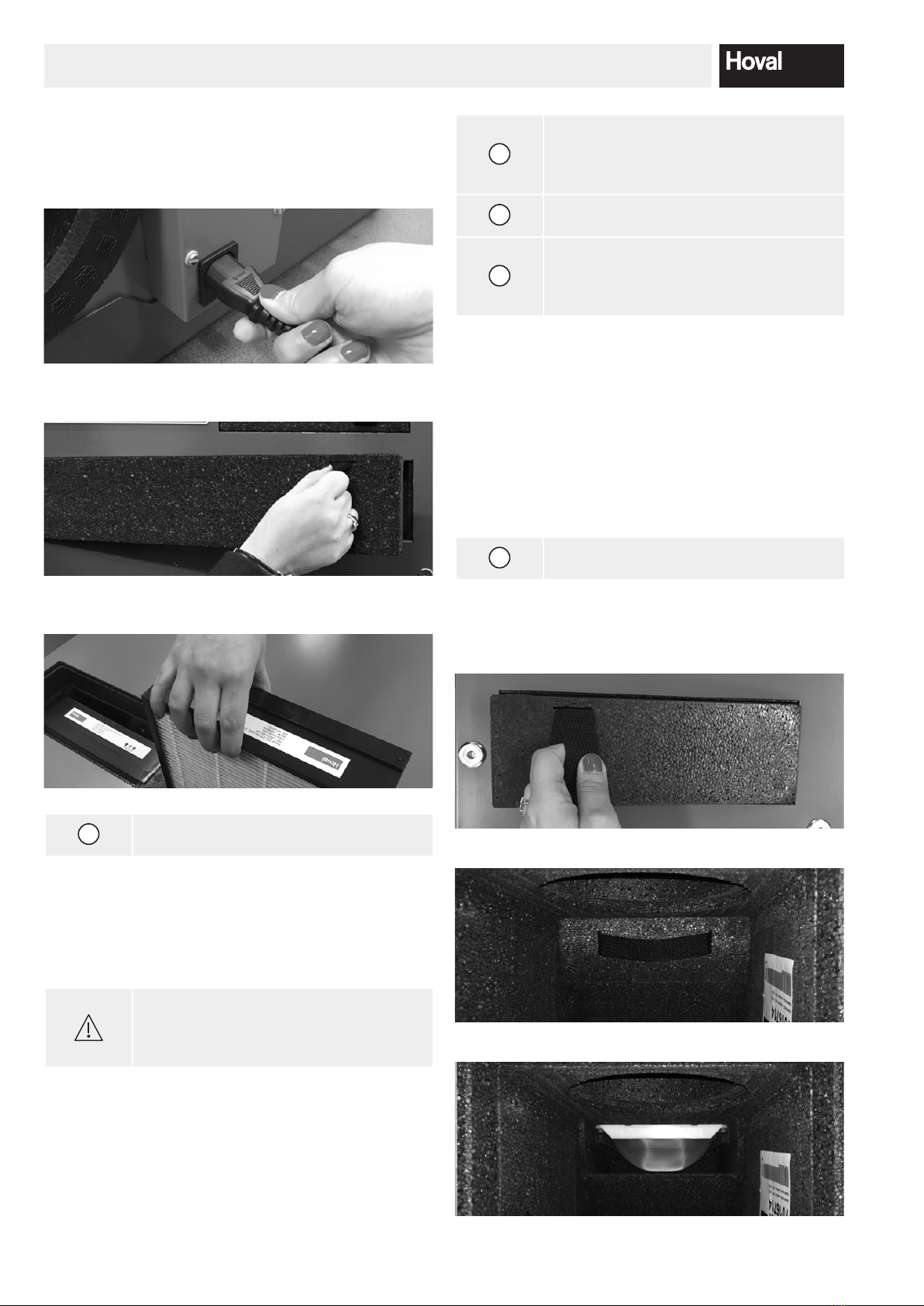

Functional check

Reliable and safe functioning of the HomeVent®com-

fort ventilation unit and optimum eciency can only be

guaranteed if the unit is serviced regularly. Please also

regularly check the other components of your comfort

ventilation system, such as the fresh air intake, supply

and extract air ports and exhaust air grille, Supply and

extract air openings and exhaust air grille.