2

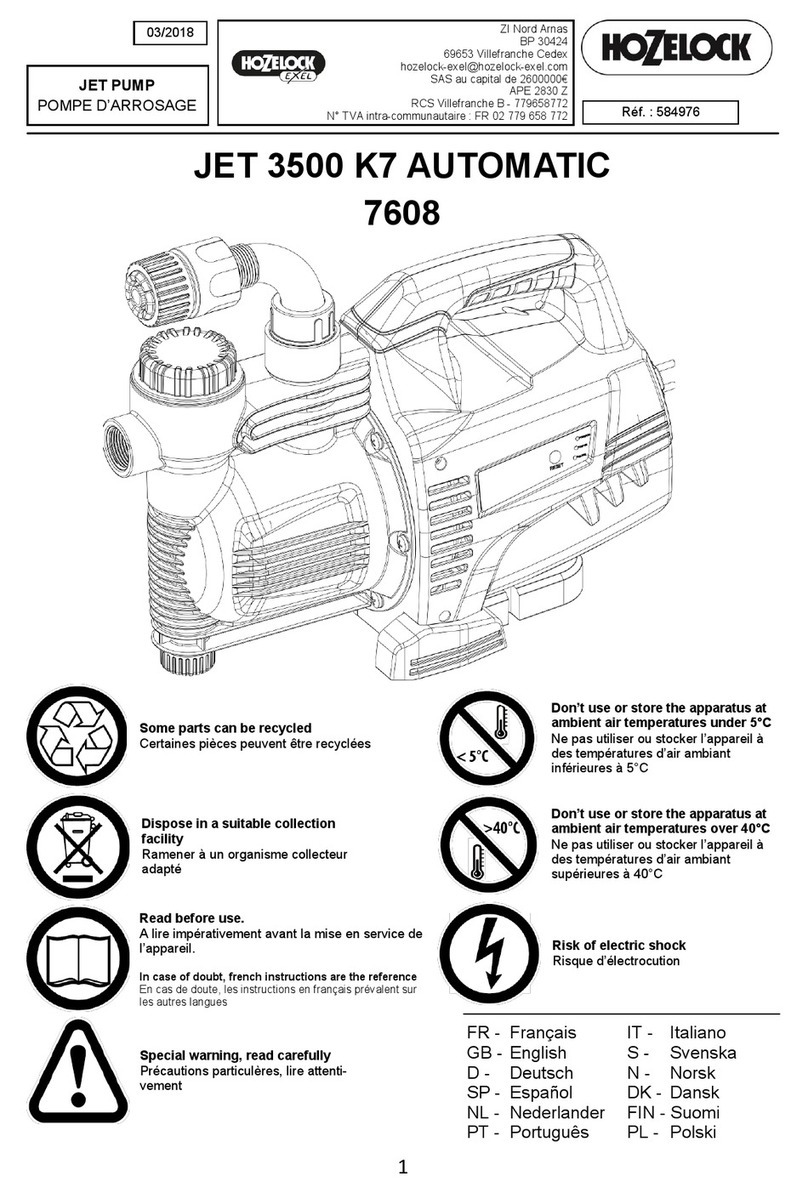

GB

CONTENTS

1 - Safety Measures……………………….... p.2

2 - Area of application……………………..... p.2

3 - Technical characteristics and

performance ………………………………....... p.3

4 - Description ............................................... p.3

5 - Preparation - First use ……………………. p.3

6 - Maintenance and storage.......................... p.4

7 - Operation faults / solutions ………………. p.4

8 - Warranty ................................................... p.5

9 - EC declaration of conformity……………... p.5

Illustrations and performance curve…………. p.5

For safety reasons, this appliance can be

used by children aged from 8 years and

above and persons with reduced physi-

cal, sensory or mental capabilities or lack

of experience and knowledge if they have been

given supervision or instruction concerning use

of the appliance in a safe way and understand the

hazards involved. Children shall not play with the

appliance. Cleaning and user maintenance shall

not be made by children without supervision.

1 - SAFETY MEASURES

READ CAREFULLY BEFORE USE

The user is responsible to third parties for all matters

resulting in the use of the pump (electrical, hydraulic

installation, etc ...). In France, comply with standard

NF C15-100 of 07/00, which governs low voltage

electrical installations. In other countries, comply with

local regulations.

Before using the pump, it is therefore advisable to

have an experienced electrician check that the neces-

sary safety measures on the electrical network are

observed.

The supply characteristics indicated on the pump

rating plate must correspond to the characteristics of

the electrical network.

For safety reasons, the electrical network that powers

your pump must be equipped with a differential circuit

breaker and grounded plugs.

When using the pump in a garden pond or similar

areas, the power supply must be equipped with a

residual current device (RCD) having a rated residual

operating current not exceeding 30 mA.

If you add an extension cord, it must be of type H05

RNF with the same section as the power cable of

your pump, with a waterproof connection plug.

Never carry the pump by the power supply

cable (C) or the float (B), but by the carrying

handle (F).

This pump is intended for prolonged use, however it

is not recommended to operate it for more than 2h

without stopping and cooling it.

Do not make any changes to the pump. Do

not modify or attempt to access the pump in

any way.

If the appliance or the supply cord is dama-

ged, it must be repaired by manufacturer, its service

agent or qualified person.

Our guarantee is excluded for the normal wear of the

material, deterioration or accidents resulting from a

faulty and abnormal use of the equipment, or due to a

modification of the pump or an intervention on the

electric part.

In case of non-compliance with the instruc-

tions, the user incurs a risk that can lead to

electrocution.

2 - AREA OF APPLICATION

Hozelock evacuation pumps are intended for private,

domestic use. They allow clean water or water with

particles up to 15 mm to be evacuated or transferred.

This pump is not designed to be used in a swimming

pool.

The temperature of the water drawn must not exceed

35°C.

THIS PUMP MUST NOT BE RUN DRY

Important: this pump is not suitable for

evacuating salt water, corrosive products,

inflammable, explosive or food-related

liquids or foodstuffs.

Do not dispose of electrical appliances as

unsorted municipal waste, use separate

collection facilities. Contact you local go-

vernment for information regarding the

collection systems available.

If electrical appliances are disposed of in landfills or

dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging

your health and well-being.

When replacing old appliances with new ones, the

retailer is legally obligated to take back your old ap-

pliance for disposals at least free of charge.

The pump's packaging is 80% recyclable.

The appliance and its accessories contain

materials (including plastics) that can be

recycled.