Important safety information

NOTE: The extension bars that ship with this kit are only

for use with Compaq/HP models EO4500, EO4501,

EO4502, EO4503, EO4504, EO4505, EO4506,

HSTNR-P011, and HSTNR-P012 Power Distribution

Control Units and HP Uninterruptible Power Supplies

(UPS).

WARNING: To reduce the risk of personal injury from

electric shock, do not remove the cover. There are no field-

serviceable or user-serviceable components inside.

WARNING: A risk of personal injury from electric shock

and hazardous energy levels exists. The installation of

options and routine maintenance and service of this

product must be performed by individuals who are

knowledgeable about the procedures, precautions, and

hazards associated with AC power products.

Follow these safety precautions when connecting multiple hardware

components to power sources.

WARNING: To reduce the risk of personal injury or

damage to the equipment:

•Plug the input power cord into a grounded (earthed)

electrical outlet that is located near the equipment and

is easily accessible.

•Be sure that the load products connected to the mPDU

are adjusted for, or otherwise capable of operation

from the same line voltage supplying the mPDU. Failure

to verify the voltage can lead to severe equipment

damage.

•Do not overload the mPDU. The total input current

rating of all equipment connected to each output

cannot exceed the total output rating marked on the

mPDU.

WARNING: To reduce the risk of personal injury from

high-leakage current, verify earth connection before

connecting the power supply.

The summation of input power for multiple pieces of

information technology equipment through the use of

power products can result in high-leakage currents.

If the total system leakage current for a system of

components exceeds 3.5 mA:

•The use of a detachable input power cord is

prohibited.

•The input power cord must be securely attached, and it

should be connected to the AC mains by hardwiring or

through the use of a non-residential, industrial-style

plug that maintains positive earth connection.

•If the total system leakage current through the ground

conductor exceeds 5% of the input current per line

under normal operating conditions, the system loads

should be divided among multiple power connections.

Regulatory compliance information

All regulatory certifications for these products were obtained under

the following agency series numbers:

Control unit Series number

228481-001 EO4500

228481-002 EO4501

228481-003 EO4502

228481-004 EO4503

228481-006 EO4504

228481-007 EO4505

228481-008 E04506

435530-001 HSTNR-P011

435530-003 HSTNR-P012

458745-001 HSTNR-P016N

481337-001 HSTNR-P017

484168-001 HSTNR-P016-A

Extension bar Series number

411273-001 HSTNR-PS02

411273-002 HSTNR-PS03

228480-003 EO4602

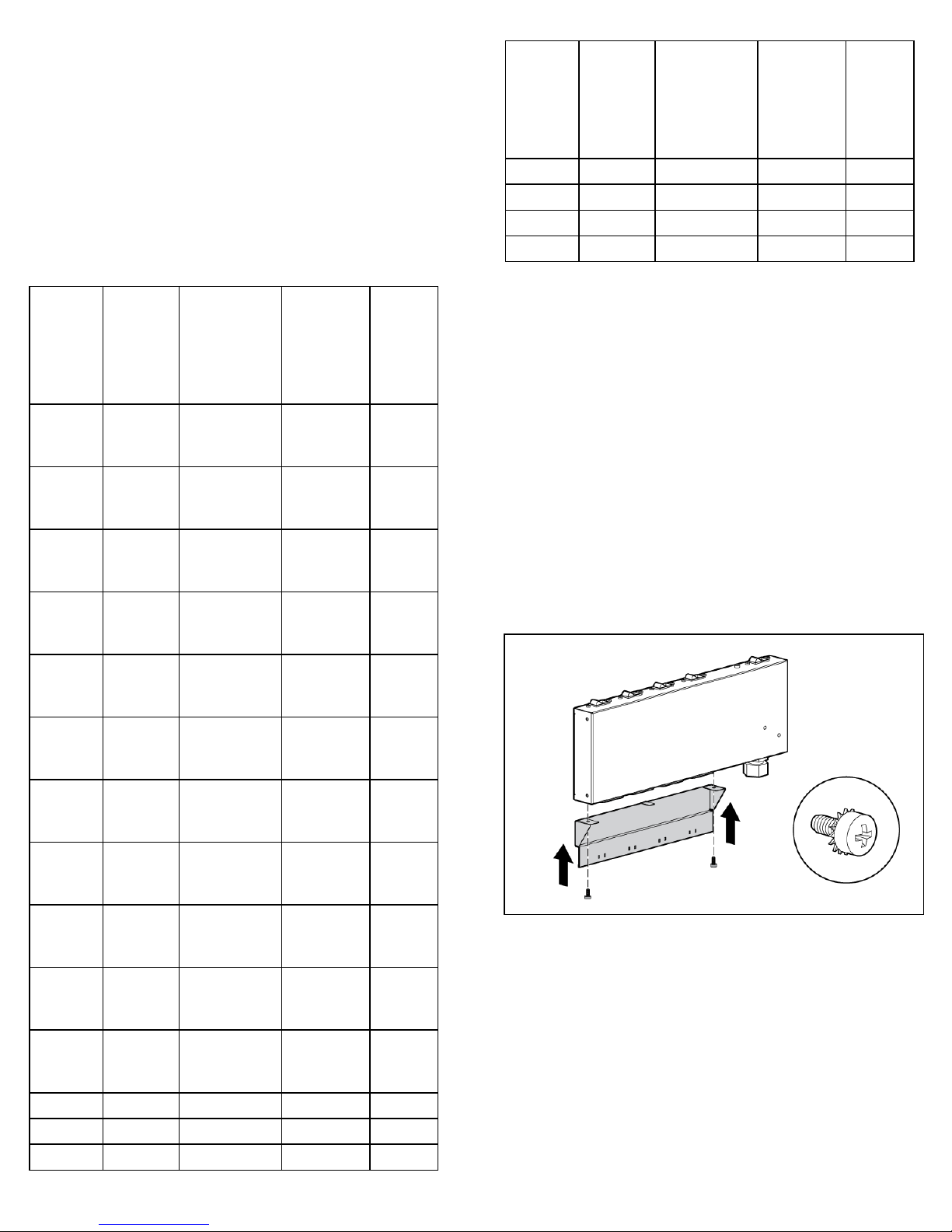

Kit contents

Control unit hardware (if included)

The following hardware pieces are included:

•Control unit with extension bars

o0U mounting brackets (2)

o1U mounting brackets (2)