Contents

1Safety........................................................................................................................2

1.1 Symbols used............................................................................................................ 2

1.2 Regulation use .......................................................................................................... 2

1.3 General safety........................................................................................................... 3

1.4 Use in explosive environments.................................................................................. 3

1.5 Technical condition of the linear unit.......................................................................... 4

1.6 Modifications to the linear unit ................................................................................... 4

1.7 Requirements for personnel....................................................................................... 5

1.8 Obligations of the operating company........................................................................ 5

2Warranty ...................................................................................................................6

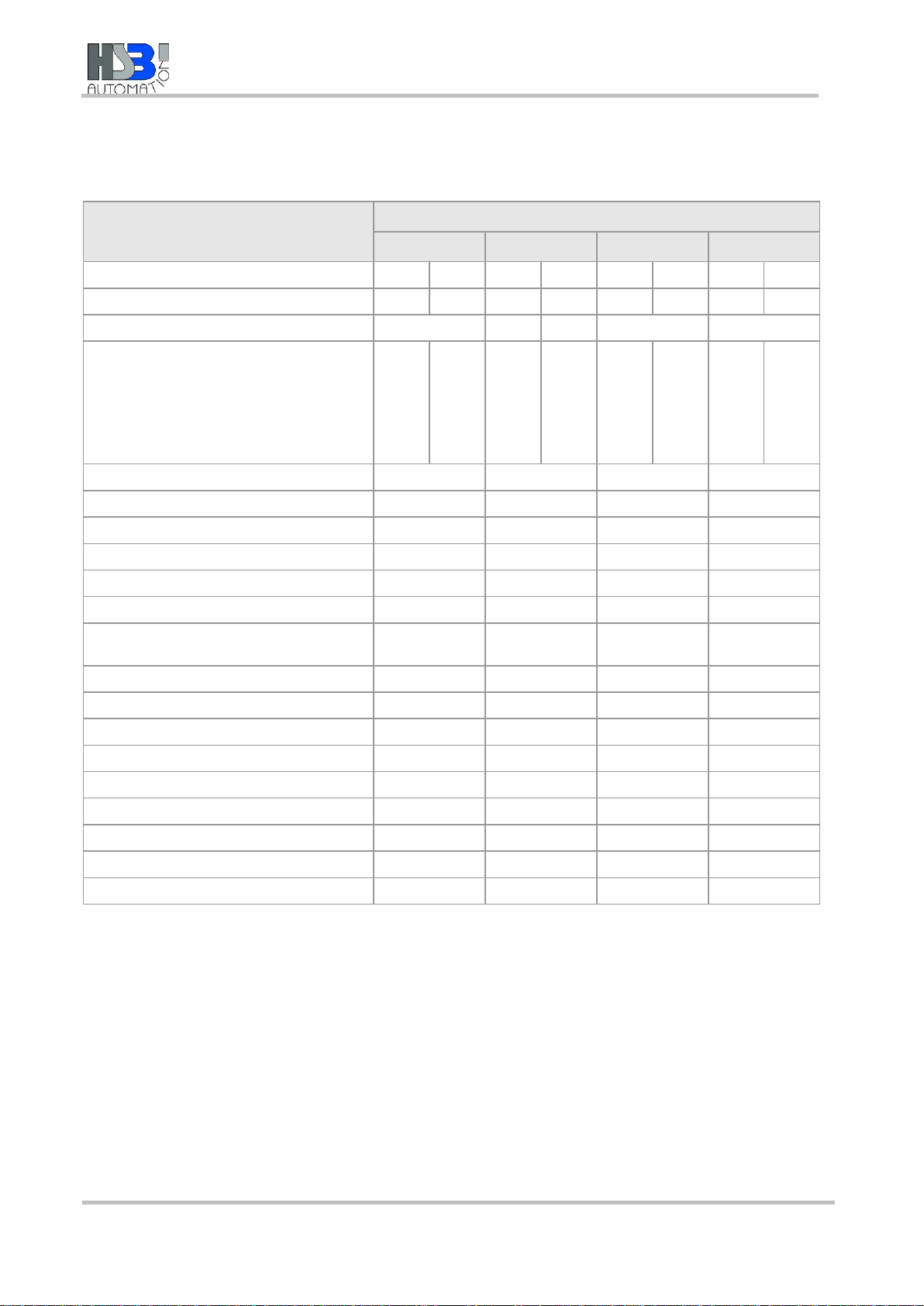

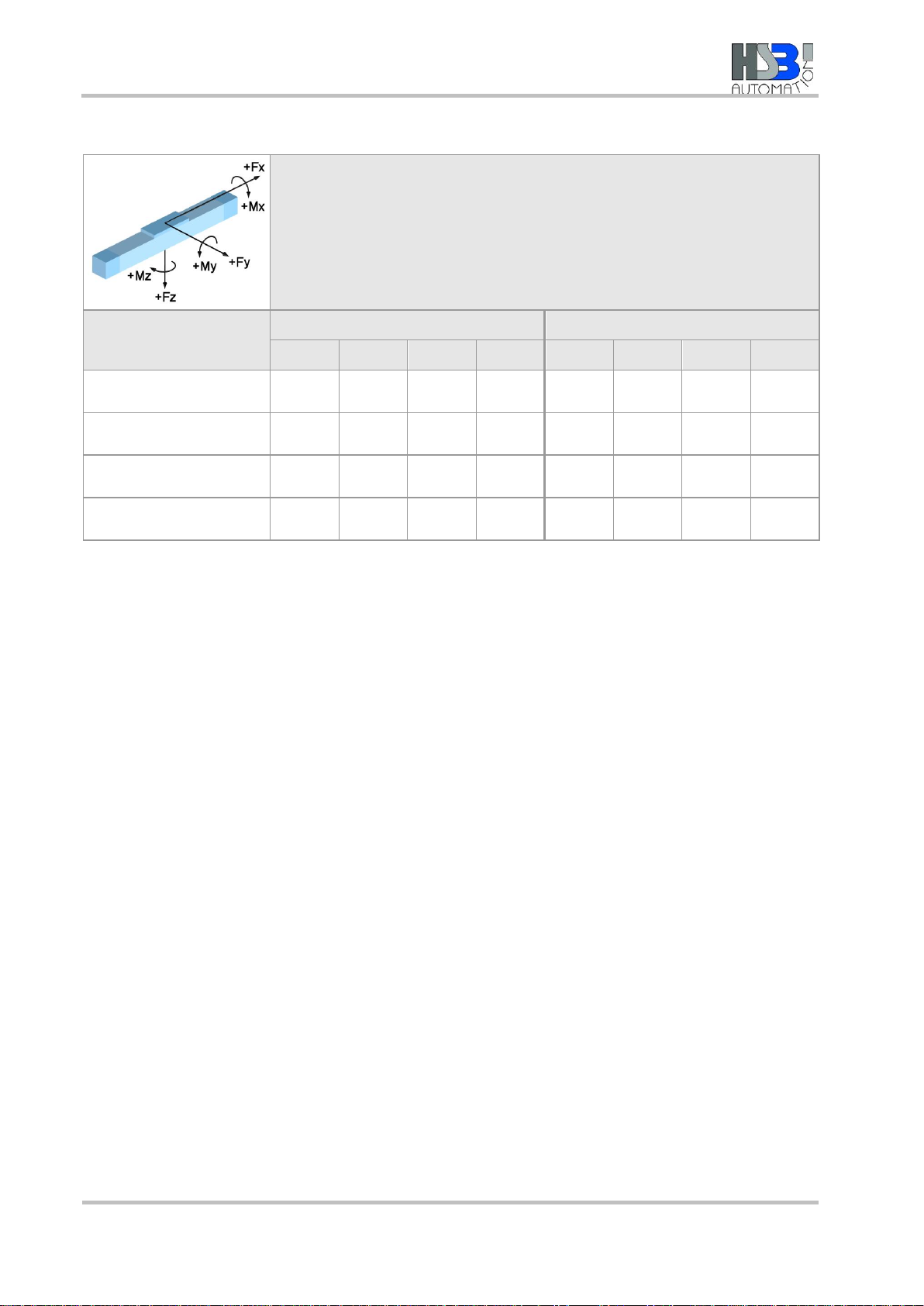

3Technical data –Standard model...........................................................................7

4Product description...............................................................................................11

5Transportation and storage ..................................................................................14

6Installation and adjustment...................................................................................15

6.1 Mounting the linear unit by the base plate................................................................ 15

6.2 Screwing the linear unit into place from below......................................................... 16

6.3 Setting maximum travel........................................................................................... 16

6.3.1 Setting the positions of the inductive limit switches ..................................17

6.3.2 Setting the positions of the mechanical limit switches...............................19

6.4 Mounting a drive unit ............................................................................................... 20

6.4.1 Mounting a motor.....................................................................................21

7Start-up...................................................................................................................22

8Operation................................................................................................................24

9Shutdown................................................................................................................25

10 Maintenance...........................................................................................................26

10.1 Lubrication............................................................................................................... 26