2.1. Maintenance and Repair

Maintenance and repair of the Biospray fogger and safety-relevant assemblies require qualified,

specialised training and a workshop equipped with special tools and test devices. We advise that any

essential work is completed by the manufacturer. Please contact us with any requirements.

2.2. Replacement Parts

The continued operation and safety of your device is dependent on the quality of any replacement parts

that are used. We advise only original manufacturer’s replacement parts, thus guaranteeing the highest

material quality, dimensional accuracy, functionality, and critically, safety. Original replacement parts

and accessory parts are available from our head office. Original replacement parts are essential in

order to maintain equipment warranty.

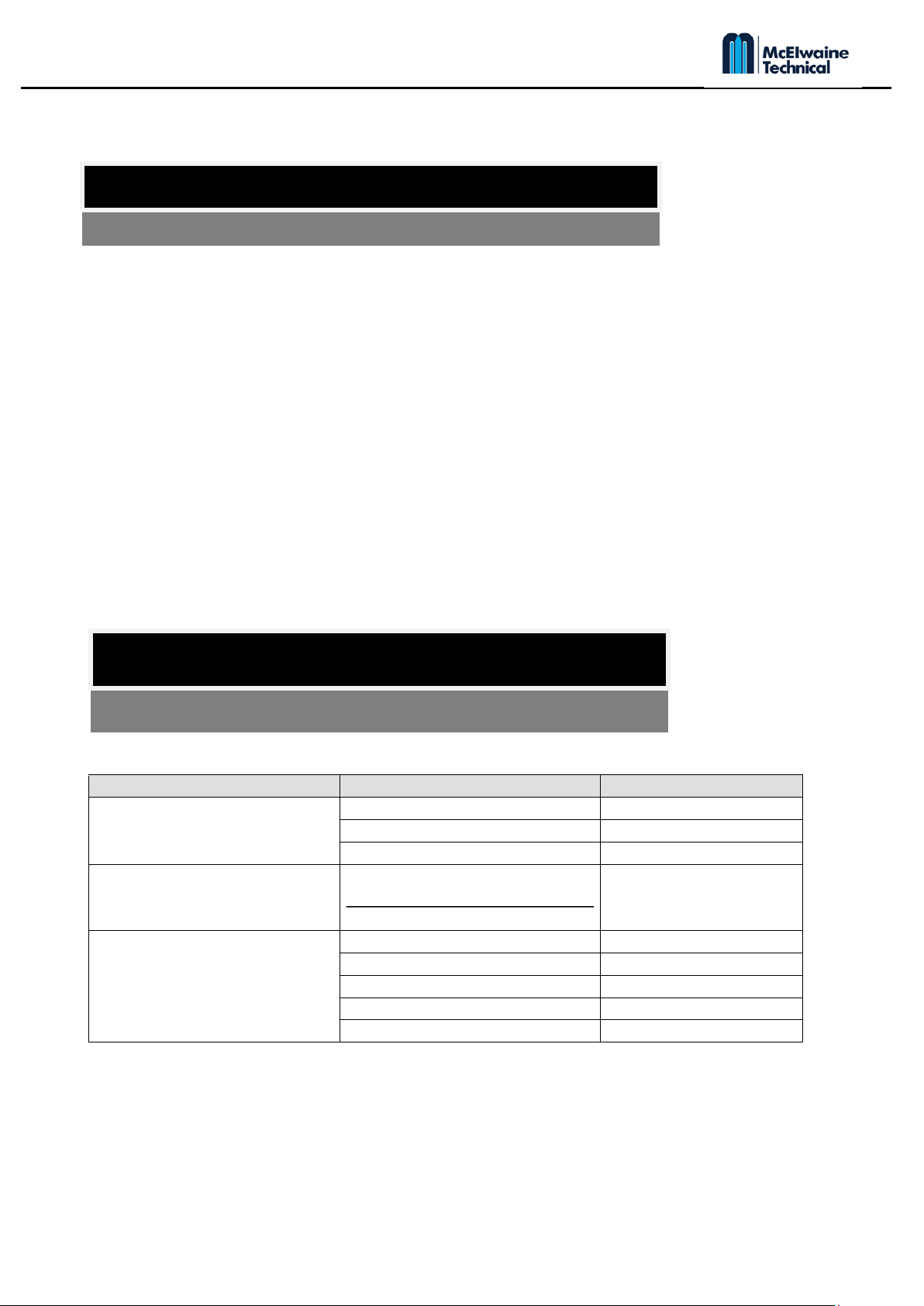

2.3. Guarantee

The manufacturer guarantees quality performance and will assume the costs for defect remediation by

replacing the defective parts in the case of material or manufacturing defects that occur within the

guarantee period after the date of purchase. Please note that specific guarantee conditions apply in

some countries. Warranty terms specifically exclude damages due to the following:

•Non-compliance with the operating instructions.

•Neglecting required maintenance and repair work.

•Normal wear and tear.

•Obvious overload through persistently exceeding the upper performance limits.

•The use of force, improper handling, misuse, or accident.

•Intervention by non-specialised persons, or improper repair attempts.

•The use of unsuitable replacement parts or parts other original manufacturer parts to the

extent that they cause damage.

•Using substances other than liquids.

•Using unsuitable solution stored for excessive periods in the unit.

•Damages that can be traced to implementation conditions from rental of the unit.

Cleaning, care, and adjustment work are not recognized as guarantee performances. All guarantee

work must be carried out by the original manufacturer, on return-to-base terms.