This multimeter has been designed according to IEC-1010 concerning electronic measuring instruments with an over-voltage category (CAT II)

and pollution 2.

Follow all safety and operating instructions to ensure that the meter is used safely and is kept in good operating condition.

1.1 PRELIMINARY

1.1.1 When using the meter, the user must observe all normal safety rules concerning:

•protection from the dangerous electric current

•protection against misuse

1.1.2 When the meter is delivered, check that it has not been

damaged in transit.

1.1.3 When poor condition under harsh presentation or

shipping conditions caused, inspect and confirm this meter without delay.

1.1.4 The leads must be in good condition. Before using verify that the insulation on test leads is not damaged and/or the leads wire is not

exposed.

1.1.5 full compliance with safety standards can be

guaranteed only if used with test leads supplied. If

necessary, the must be replaced with the same model

or same electric ratings.

1.2 DURING USE

1.2.1 Never exceed the protection limit values indicated in specifications for each range of measurement.

1.2.2 When the meter is linked to a measurement circuit, do not touch unused terminals.

1.2.3 When the value scale to be measured is unknown beforehand, set the range selector at the highest position.

1.2.4 Do not measure voltage if the voltage on the terminals exceeds 1000V above earth ground.

1.2.5 Always be careful when working with voltages above 60V DC or 30V AC rms, keep fingers behind the probe barriers while measuring.

1.2.6 before rating the range selector to change functions, disconnect test leads from the circuit under test.

1.2.7 Never connect the meter leads across a voltage sources while the function switch is in the current, resistance, diode or continuity mode.

Dong so can damage the meter.

1.2.8 When carrying out measurements on TV or switching power circuits, always remember that there may be high amplitude voltages pulses

at test points, which can damage the meter.

1.2.9 Never perform resistance measurements on live circuits.

1.2.10 Never perform capacitance measurements unless the capacitor to be measured has been discharged fully.

1.2.11 If any faults or abnormalities are observed, the meter can not be used any more and it has to be checked out.

1.2.12 Never use the meter unless the rear case in place and fastened fully.

1.2.13 Please do not store or use the meter in areas exposed to direct sunlight, high temperature, humidity or condensation.

1.3 SYMBOLS

important safety information, refer to the operating manual.

Dangerous voltage may be presence.

Double insulation (protection Class II)

Earth ground

1.4 MAINTANANCE

1.4.1 Please do not attempt to adjust or repair the mete by removing the rear case while voltage is being applied. A technician who fully

understands danger involved should carry out such actions.

1.4.2 Before opening the battery cover of the meter, always disconnect test leads from all sources of electric current.

1.4.3 For continue the battery against fire, replace fuse only with the specified voltage and current ratings: F1-200mA/250V ()quick acting,

F2-10A/250V (quick acting).

1.4.4 Do not use abrasives or solvents on the meter, use a damp cloth and mild detergent only.

1.4.5 Always set the power switch to the off position when the meter is not in use.

1.4.6 If the meter is to be stored for a long period of time, the batteries should be removed to prevent damage to the unit.

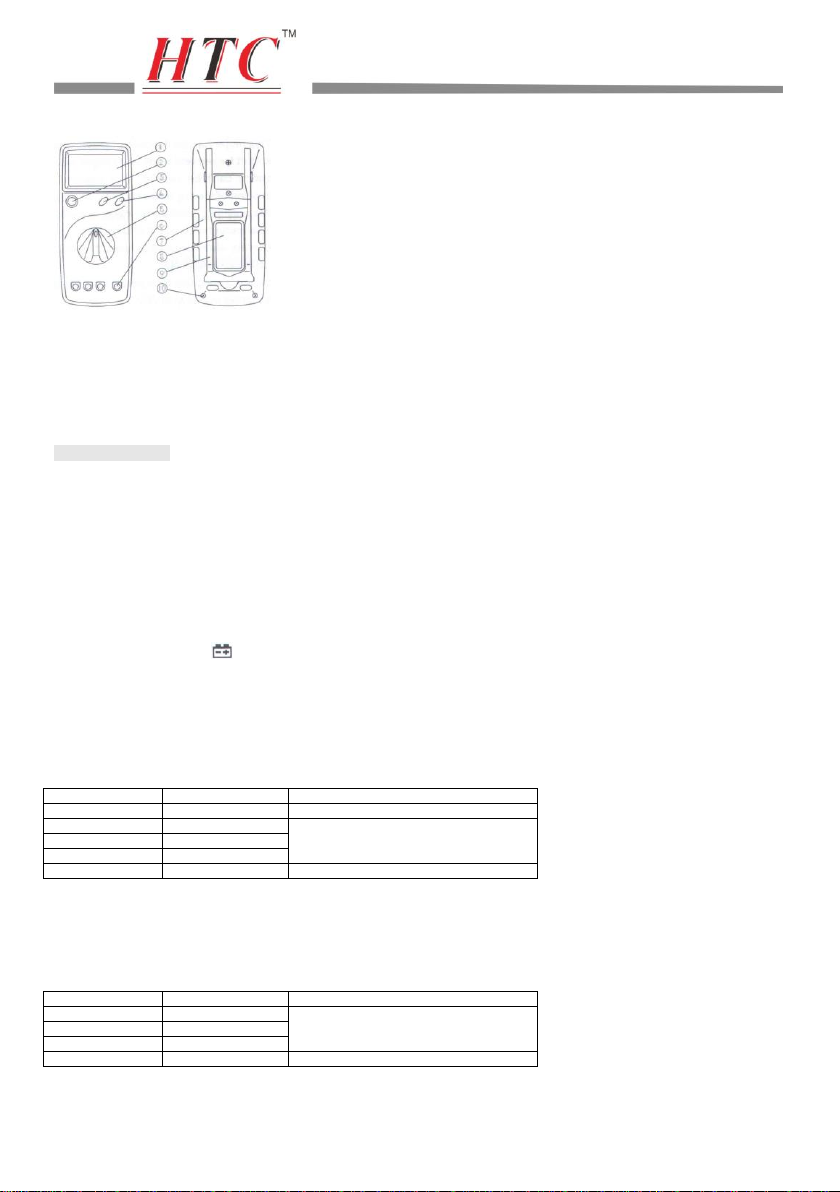

2. DESCRIPTION

2.1 NAMES OF COMPONENTS