9

GLOBAL ENERGY EFFICIENCY SPECIALIST

GAQ40S3V3B

DC-DC Converter Technical Manual V1.4

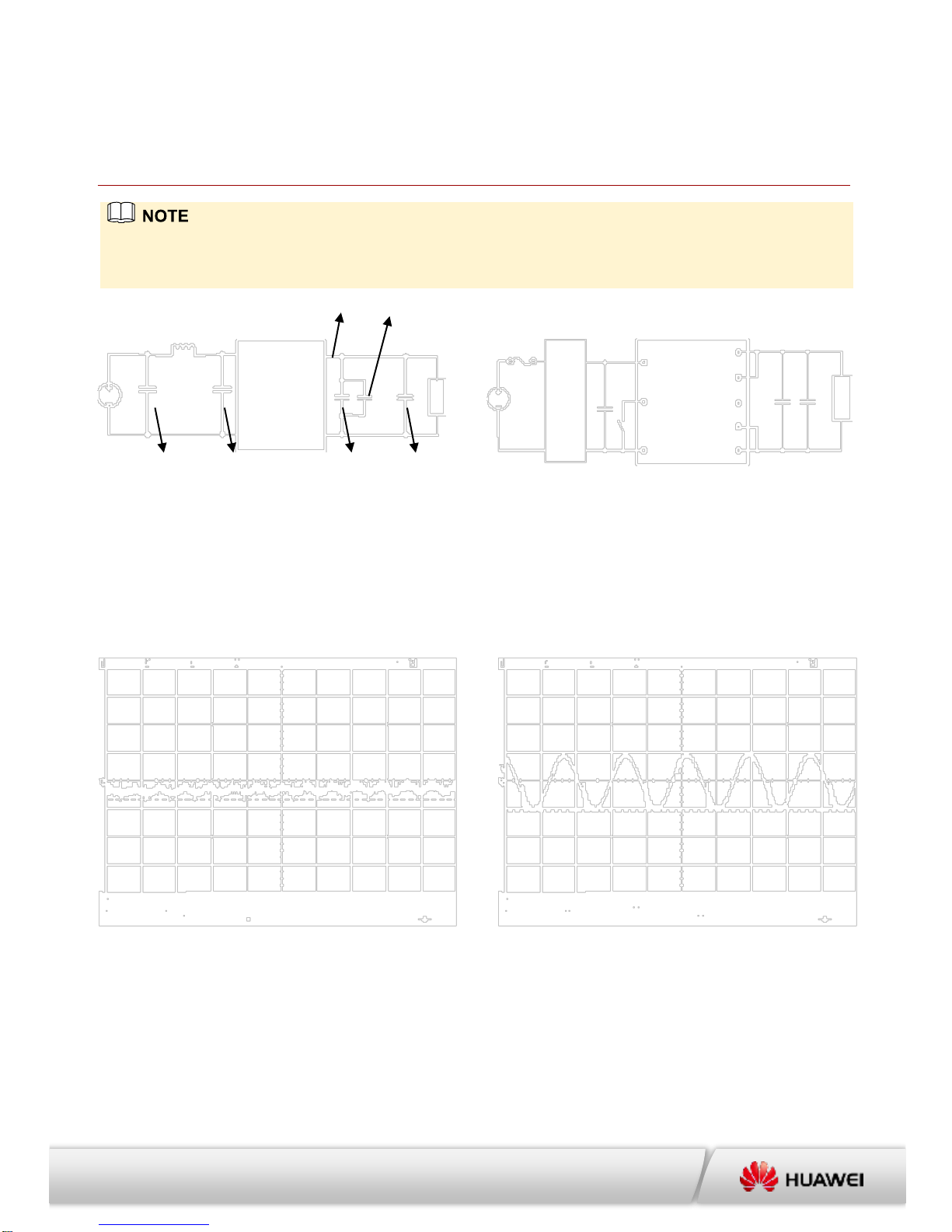

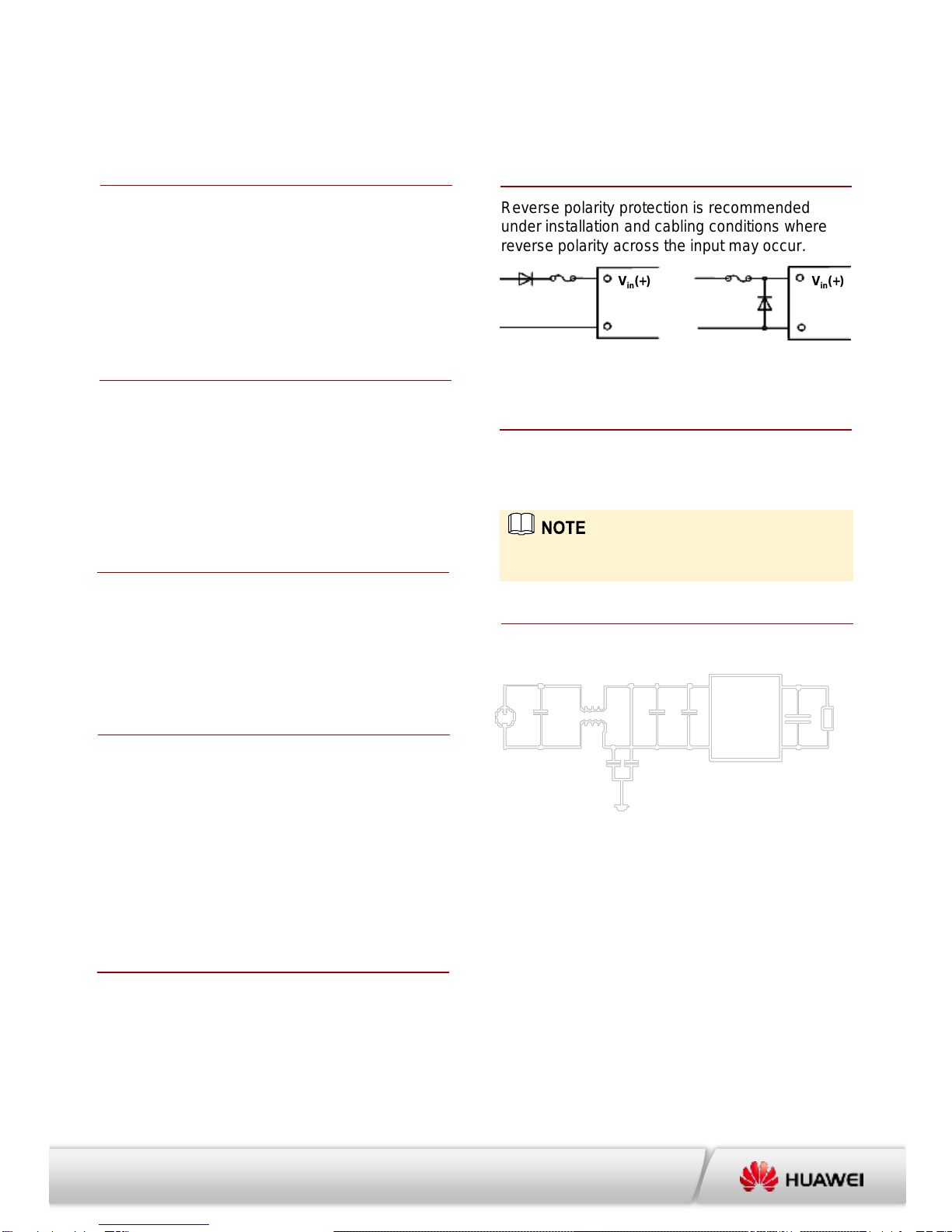

Reverse polarity protection is recommended

under installation and cabling conditions where

reverse polarity across the input may occur.

Vin(+)

Vin(–)

Vin(+)

Vin(–)

The converter has no internal fuse. To meet

safety and regulatory requirements, a 7 A fuse is

recommended.

For the acceptance standard, see the DC-DC

Converter EMC Acceptance Manual.

Recommend Reverse Polarity

Protection Circuit

Figure 19: Recommend reverse polarity protection

circuits

Recommended Fuse

EMC

Figure 20: EMC test set-up diagram

DC-DC

converter Load

C1 L1

C4 C5

C2 C3 C6

Vin(+)

Vin(–)

Vout(+)

Vout(–)

C1: Surface mount device (SMD) ceramic capacitor (100

V/1000 nF/X7R/1210)

C2: SMD ceramic capacitor (100 V/100 nF/±10%/X7R/1206)

L1: Common-mode inductor (single phase, 1320 µH/±25%/4

A/R5K/ 21 mm x 21 mm x 12.5 mm [0.83 in. x 0.83 in. x 0.49

in.]). The chip component with the same specifications can also

be used.

C4, C5: High-pressure resistant chip ceramic capacitor (22

nF/1000 V/X7R/1210)

C3: Electrolytic capacitor (100 µF/100 V)

C6: Electrolytic capacitor (470 µF/25 V)

Vs

The fuse current should be 1.5 to 2 times the maximum

operating current in actual use.

Input Undervoltage Protection

The converter will shut down after the input

voltage drops below the undervoltage protection

threshold for shutdown. The converter will start

to work again after the input voltage reaches the

input undervoltage protection threshold for

startup. For the Hysteresis, see the Protection

characteristics.

Output Overcurrent Protection

The converter equipped with current limiting

circuitry can provide protection from an output

overload or short circuit condition. If the output

current exceeds the output overcurrent

protection set point, the converter enters hiccup

mode. When the fault condition is removed, the

converter will automatically restart.

Output Overvoltage Protection

When the voltage directly across the output pins

exceeds the output overvoltage protection

threshold, the converter will enter hiccup mode.

When the fault condition is removed, the

converter will automatically restart.

Overtemperature Protection

A temperature sensor on the converter senses

the average temperature of the module. It

protects the converter from being damaged at

high temperatures. When the temperature

exceeds the overtemperature protection

threshold, the output will shut down. It will allow

the converter to turn on again when the

temperature of the sensed location falls by the

value of Overtemperature Protection Hysteresis.

MTBF

The MTBF is calculated according to the

Telcordia, SR332 Method 1 Case3.