CONTENT

1 Main usage and application ................................................................................................................................1

2 Working condition and Environment ...................................................................................................................2

2.1 working environment condition ...................................................................................................................2

2.2 Power input..................................................................................................................................................2

2.3 Safety precautions........................................................................................................................................2

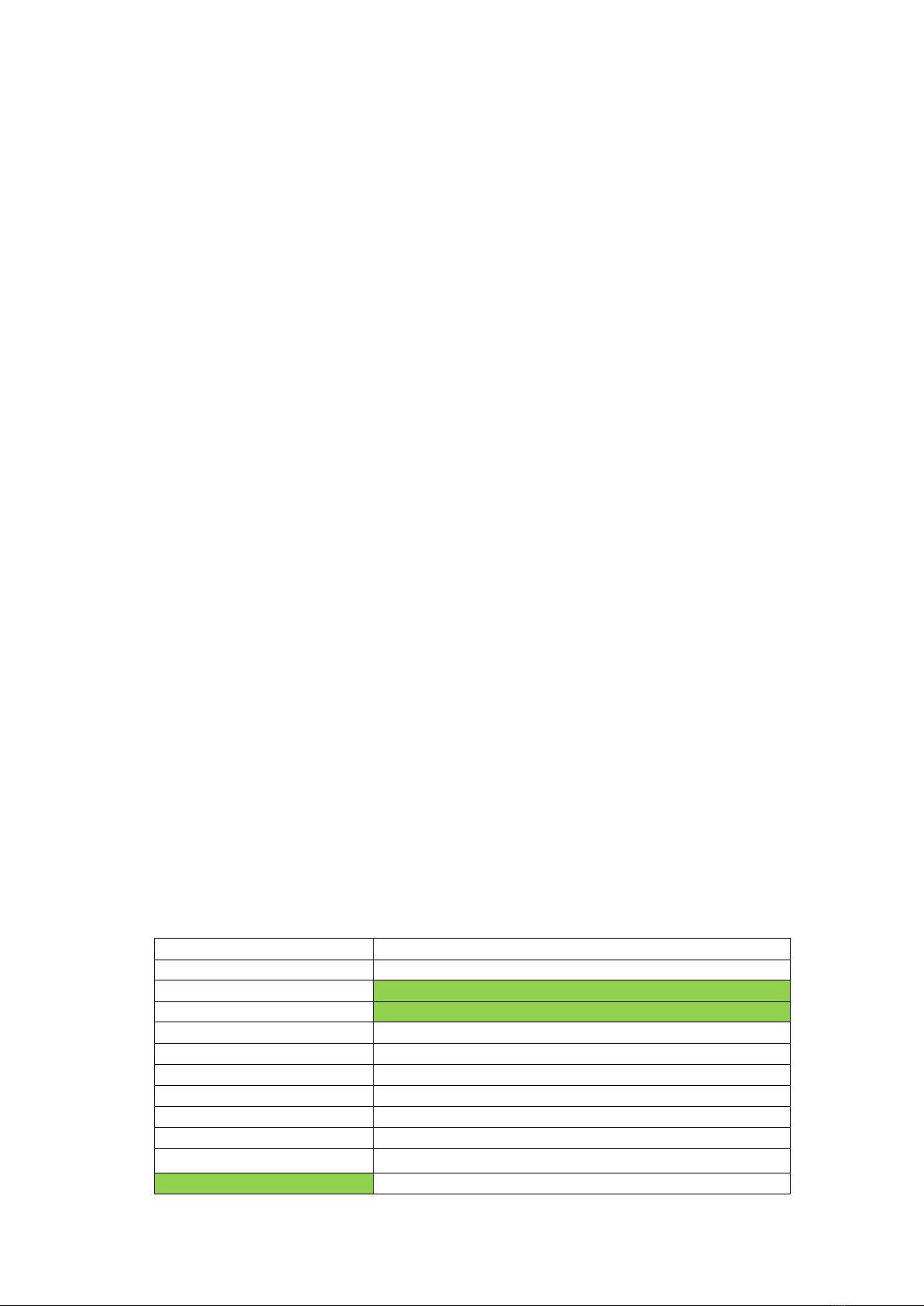

3 Technical specification.........................................................................................................................................2

3.1 Parameter.....................................................................................................................................................2

3.2 Welding electrode and related parameter setting.........................................................................................3

4 Hardware Overview.............................................................................................................................................3

5 General description .............................................................................................................................................3

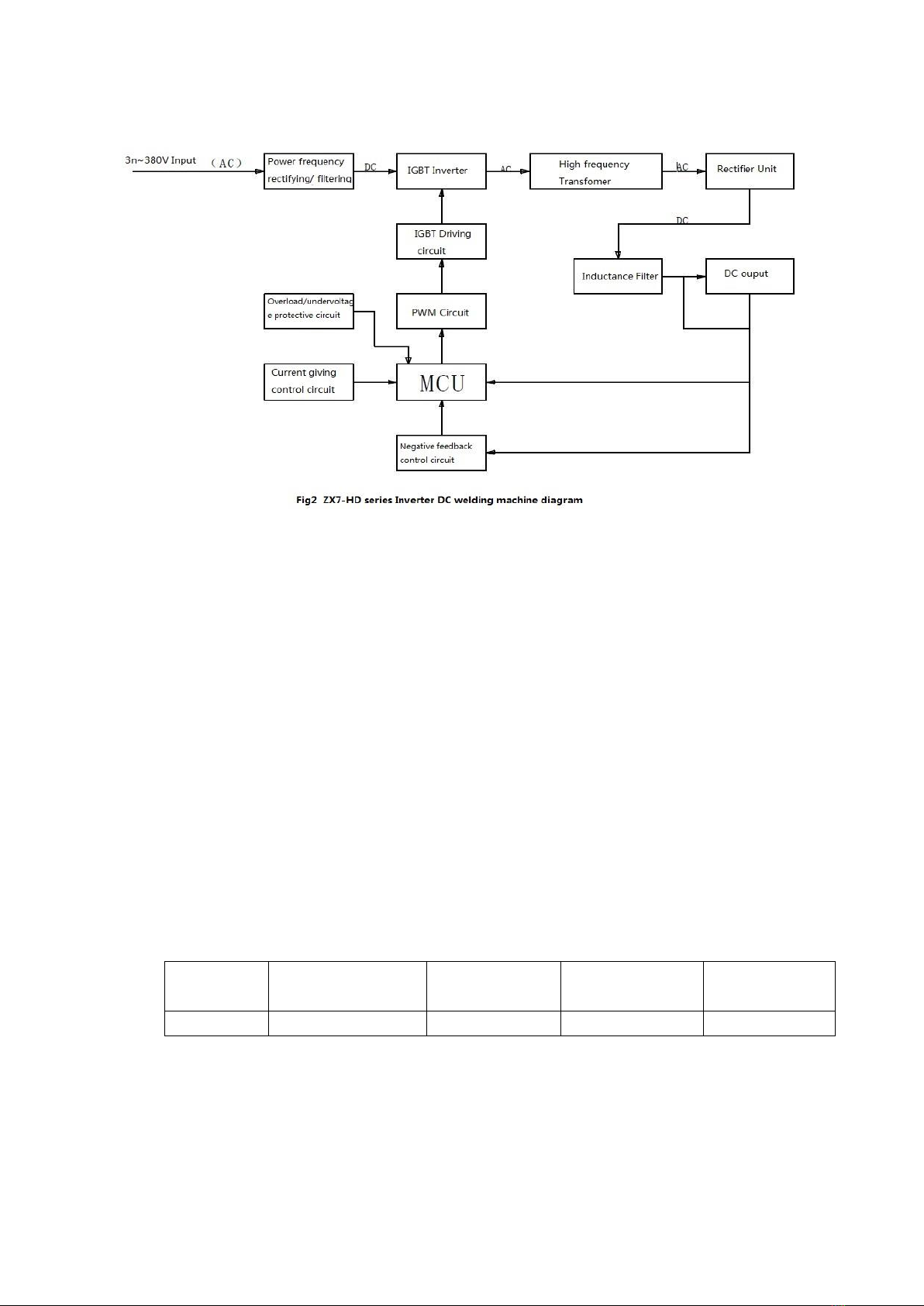

5.1 Working principal .........................................................................................................................................3

5.2 Principal diagram..........................................................................................................................................4

6 Installation and adjustment ................................................................................................................................4

6.1 The moving and lifting..................................................................................................................................4

6.2 Installation and operation conditions...........................................................................................................4

7 Operations...........................................................................................................................................................5

7.1 Panel instruction ..........................................................................................................................................5

7.2 Function introduction...................................................................................................................................6

8 Maintenance .......................................................................................................................................................6

9 Troubles and troubleshooting..............................................................................................................................7

10 Packing List........................................................................................................................................................8

11 Drawing (The principle drawing of the main circuit) ..........................................................................................9