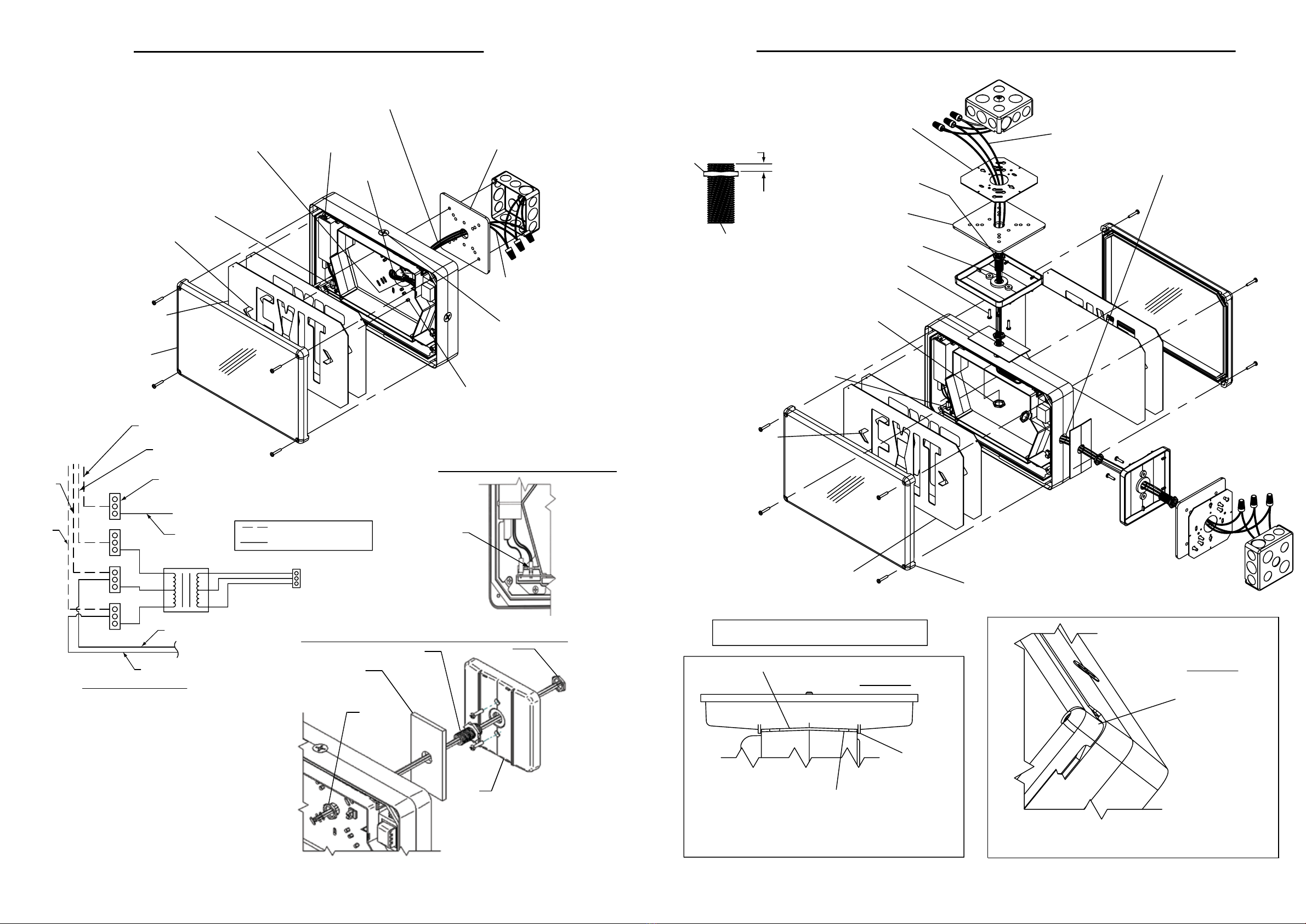

CEILING OR END MOUNT INSTALLATION

WALL MOUNT INSTALLATION

TRANSFORMER

CONNECTOR TO

LED PCB (J1)

WIRE HARNESS

FROM HEATER

ASSY 7 PIN

CONNECTOR

(WHEN PROVIDED)

TO GROUND

CONNECTION

ON FRAME

277

120

COM

TO JUNCTION

BOX

3 PIN PUSH

CONNECTOR (QTY 4)

SUPPLIED PIGTAIL LEADS

PREWIRED AT FACTORY

BLK

WHT

GREEN (GROUND)

PIGTAIL LEAD

RED

PIGTAIL LEAD

BLK

PIGTAIL LEAD

WHT

PIGTAIL LEAD

ORG

BLK

WHT

GREEN

WIRING DIAGRAM

10. REMOVE CHEVRON(S) IF REQUIRED.

DRIVE CHEVRON TOWARDS BACK

OF STENCIL BY TAPPING AROUND

THE ENTIRE PERIMITER FROM

FRONTSIDE OF STENCIL FOR CLEAN

BREAKOUT.

2. REMOVE APPROPRIATE KNOCKOUTS

FOR WALLBOX SCREWS.

4. AT TACH PRE-TINNED PIGTAIL LEADS

PROVIDED TO AC INPUT CONDUCTORS.

3. IF USING CONDUIT, REMOVE

PIPE PLUG, OTHERWISE

REMOVE CENTER KNOCKOUT.

5. REMOVE ADHESIVE BACKING FROM

MOUNTING GASKET & APPLY TO

EXIT BACKPLATE.

6. ROUTE PIGTAIL LEADS THRU CENTER

KNOCKOUT IN BACKPLATE & MOUNT

SIGN TO WALLBOX.

7. AT TACH ADHESIVE WIRING SADDLE

AND ROUTE WIRES INTO CHANNEL.

8. ROUTE PIGTAILS THRU LIGHTBOX

(SEE WIRING DIAGRAM & DETAIL 1)

AND MAKE PROPER CONNECTIONS USING

PUSH CONNECTORS.

9. WHEN PROVIDED, AT TACH 2-PIN BATTERY CONNECTOR

TO PC BOARD AS SHOWN. (SEE BATTERY CONNECTION DETAIL)

11. CONFIRM ALL WIRING IS DRESSED

PROPERLY, HANG STENCIL & DIFFUSER

ONTO FRAME PINS.

12. SEAT COVER & SECURELY TORQUE

COVER SCREWS TO 16 IN-LBS. (SEE DETAIL 2)

AC TRANSFORMER

120VAC-CONNECT BLACK & WHITE LEADS.

277VAC-CONNECT RED & WHITE LEADS.

13. REMOVE CHEVRON(S) IF

REQUIRED. DRIVE

CHEVRON TOWARDS

BACK OF STENCIL BY

TAPPING AROUND THE

ENTIRE CHEVRON

PERIMITER

FROM FRONTSIDE OF

STENCIL FOR CLEAN

BREAKOUT.

3. AT TACH PRE-TINNED PIGTAIL LEADS

PROVIDED TO AC INPUT CONDUCTORS.

2. REMOVE PIPE PLUG.

4. FEED LEADS THROUGH CENTER OF

UNIVERSAL MOUNTING PLATE AND

AT TACH PLATE TO ELECTRICAL BOX.

5. AFFIX NUT TO PIPE NIPPLE. SLIP

THROUGH CANOPY CENTER HOLE AND

AFFIX SECOND NUT ONTO PIPE NIPPLE

AND TIGHTEN. THIS WILL LOCK PIPE

NIPPLE TO CANOPY. (SEE DETAIL)

7. ROUTE PIGTAILS THRU GASKET & CANOPY.

6. REMOVE ADHESIVE BACKING FROM

MOUNTING GASKET & APPLY TO

CANOPY.

8. WITH SCREWS SUPPLIED (QTY 2) SECURE

CANOPY TO UNIVERSAL MOUNTING PLATE

9. REMOVE ADHESIVE BACKING FROM FRAME

GASKET, ROUTE PIGTAILS THROUGH GASKET

& APPLY TO CANOPY. (SEE DETAIL 1)

10. ROUTE PIGTAILS THROUGH EXIT FRAME

AND PIPE NIPPLE NUT. AFFIX NUT TO

PIPE NIPPLE AND TIGHTEN TO SECURE

EXIT FRAME. (SEE DETAIL 1)

11. ROUTE PIGTAILS TO PUSH CONNECTORS.

(SEE WIRING DIAGRAM & DETAIL 1)

12. WHEN PROVIDED, AT TACH 2-PIN BATTERY

CONNECTOR TO PC BOARD AS SHOWN.

14. CONFIRM ALL WIRING IS DRESSED PROPERLY,

HANG STENCIL/DIFFUSER ONTO FRAME PINS. 15. SEAT COVER(S) & SECURELY TORQUE

COVER(S) SCREWS TO 16 IN-LBS. (SEE DETAIL 2)

DETAIL 1

CANOPY GASKET

COMPRESSION STOPS

CANOPY

ANTI-ROTATION

RIBS

NOTE: PIPE NIPPLE NUT INSIDE EXIT FRAME SHALL BE TORQUED TO 40 IN-LBS

SO THAT CANOPY GASKET COMPRESSION STOPS SEAT AGAINST EXIT

FRAME. THIS INSURES THAT THE GASKET IS COMPRESSED PROPERLY

TO SEAL SIGN & SIGN WILL BE SECURE AGAINST ROTATING ON CANOPY.

GASKET

NOTE: CLEAR POLYCARBONATE COVER(S) ARE SIMILAR TO THE CANOPY IN THAT THEY

ALSO HAVE COMPRESSION STOPS (COVER HAS THEM AT ALL 4 CORNERS)

THAT SEAT AGAINST EXIT FRAME. THIS INSURES GASKET WILL BE

COMPRESSED PROPERLY TO SEAL SIGN.

DETAIL 2

SEAT COVER TO FRAME

CENTER KNOCKOUT

1. USE SPANNER SCREW BIT (PROVIDED)

TO REMOVE & TIGHTEN ALL SPANNER

SCREWS.

1. USE SPANNER SCREW BIT (PROVIDED)

TO REMOVE & TIGHTEN ALL SPANNER

SCREWS.

CANOPY PIPE NIPPLE

NUT

APPROX. 3/16"

NOTE: FOR END MOUNTED SINGLE FACED SIGNS, THE

BACKPLATE AND CLEAR COVER WITH STENCIL/DIFFUSER

CAN BE SWAPPED FOR MOUNTING VERSATILITY

A

IMPORTANT: TO WEATHERPROOF FOR OUTDOOR INSTALLATION,

BE SURE TO SEAL ALL OPENINGS — MOUNTING, CONDUIT, ETC.

IMPORTANT: TO WEATHERPROOF FOR OUTDOOR INSTALLATION,

BE SURE TO SEAL ALL OPENINGS — MOUNTING, CONDUIT, ETC.

TORQUE BACK PLATE

SCREWS TO 20 IN-LBS.

REQUIRED NEMA 4X RATED WALL MTG DETAIL

NUT

TORQUE TO

40 IN-LBS

1/4-IN. THICK CANOPY

BACKPLATE

GASKET

(NEMA 4X ONLY)

MOUNT POTTED PIPE NIPPLE (SHORT END)

TO CANOPY & SECURE WITH NUT SUPPLIED.

CANOPY

NUT

TORQUE TO

50 IN-LBS

93024663

FOR NEMA SEE NEMA MOUNTING DETAIL

BATTERY CONNECTION DETAIL

2-PIN BATTERY

CONNECTION

93021641