The BH balancer is designed to be hung above the work

area from a stationary support, such as an eye bolt, or a

movable trolley (Fig 1). For best operation, balancer

should be hung directly above work area so that tool is

lowered vertically, not at an angle, when in use (compare

Fig 1-A and Fig 1-B, below). Hanging from trolley with

safety cable or chain affixed to second trolley is recom-

mended (Fig 1-C). Prior to installation, check to make

sure tool weight including air hose or power cable plus

fittings falls within the range shown on the balancer seri-

al plate. Contact your local distributor if it does not.

INSTALLATION

1. Hang balancer in desired location using hook at top of

balancer. Make sure safety latch on hook is in place to

prevent unhooking.

2. Attach safety chain or cable from eye at top of bal-

ancer to either a separate support (if statically mounted)

or to separate trolley.

3. Attach tool to balance cable by lifting tool to hook. DO

NOT attempt to pull hook down to tool.

ADJUSTING TENSION

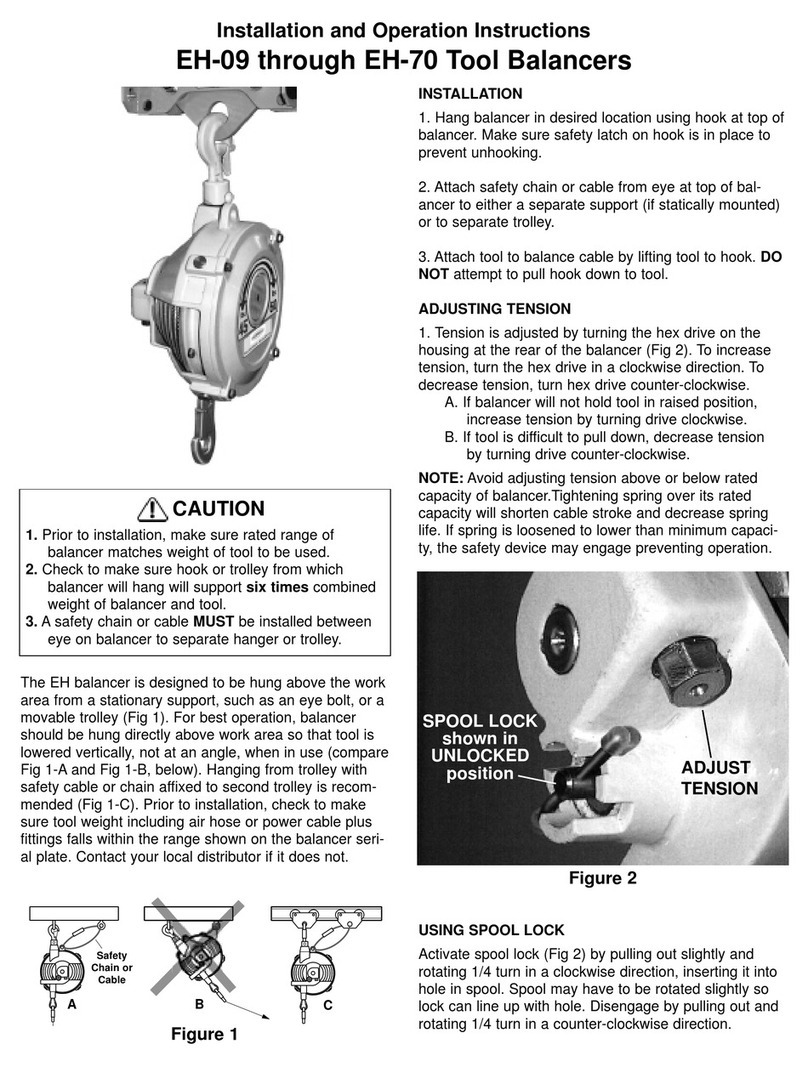

1. Tension is adjusted by turning the hex drive on the

housing at the rear of the balancer (Fig 2). To increase

tension, turn the hex drive in a clockwise direction. To

decrease tension, turn hex drive counter-clockwise.

A. If balancer will not hold tool in raised position,

increase tension by turning drive clockwise.

B. If tool is difficult to pull down, decrease tension

by turning drive counter-clockwise.

NOTE: Avoid adjusting tension above or below rated

capacity of balancer.Tightening spring over its rated

capacity will shorten cable stroke and decrease spring

life. If spring is loosened to lower than minimum capaci-

ty, the safety device may engage preventing operation.

USING SPOOL LOCK

Activate spool lock (Fig 2) by pulling out slightly and

rotating 1/4 turn in a clockwise direction, inserting it into

hole in spool. Spool may have to be rotated slightly so

lock can line up with hole. Disengage by pulling out and

rotating 1/4 turn in a counter-clockwise direction.

Installation and Operation Instructions

BH-09 through BH-70 Tool Balancers

CAUTION

1. Prior to installation, make sure rated range of

balancer matches weight of tool to be used.

2. Check to make sure hook or trolley from which

balancer will hang will support six times combined

weight of balancer and tool.

3. A safety chain or cable MUST be installed between

eye on balancer to separate hanger or trolley.

ADJUST

TENSION

SPOOL LOCK

shown in

UNLOCKED

position

Figure 2

Figure 1

Safety

Chain or

Cable

AC

B