PSP8620311

Rev. E

5

!

WARNING

Signal Words

The signal words “DANGER,” “WARNING”

and “CAUTION” (along with their assigned

symbol) throughout this manual indicate the

degree of hazard the user may encounter.

These symbols and words are defined as:

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in

death or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

!

WARNING

!

CAUTION

CAUTION

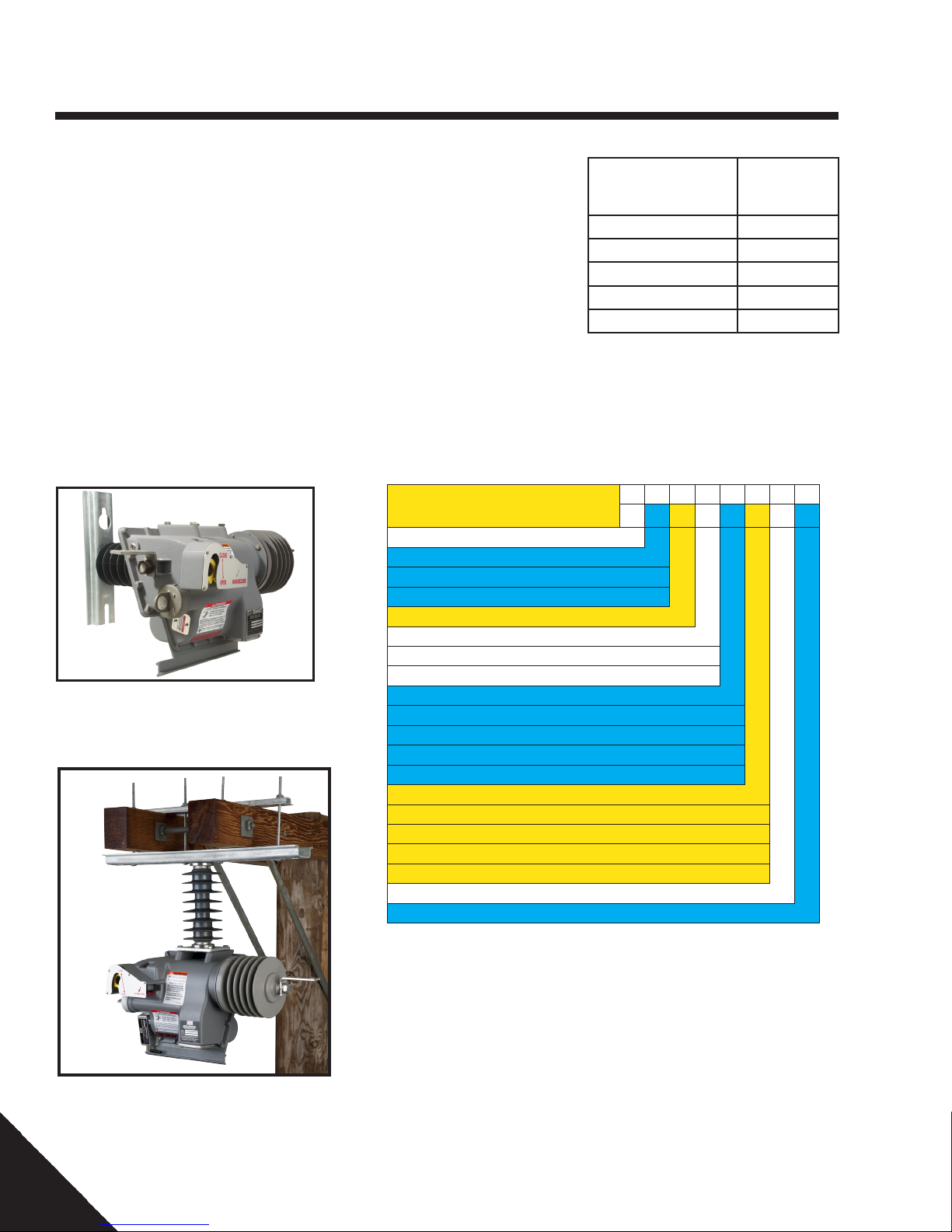

1 — Overview

Introduction

This manual is to guide you through

the programming, installation, opera-

tion and maintenance of the VERSA-

TECH®single-phase recloser. This

manual does not claim to cover

all situations that may arise during

installation. If additional informa-

tion is needed, contact your factory

representative. Nor does this manual

supersede your company’s estab-

lished guidelines and practices for

similar equipment. Take note of and

heed all danger, warning and cautions

contained in this document.

Product

The products covered by this manual

are the VERSA-TECH®single-phase

reclosers for medium voltage electri-

cal distribution circuits.

These products are designed for

distribution circuits only at their rated

capacities. They cannot be eld mod-

ied for capacities other than what

was shipped with the units.

Function

This product is a single-phase re-

closer designed to provide a means

for interrupting, sectionalizing and

isolating faults on electrical distribu-

tion systems.

CAUTION used without the safety alert

symbol indicates a potentially hazardous

situation which, if not avoided, may result in

property damage.

Qualied Person

Only qualied trained and competent

personnel that understand proper

safety procedures must select, install

and service this equipment.

Read and understand these instruc-

tions before installing, operating or

maintaining this equipment.

This guide is not a substitute for

adequate training and experience

in safety procedures for this type of

equipment.

All parts of recloser are energized.

Contact with components will cause severe

personal injury, death, or property damage.

Only qualified personnel should work on or

around this equipment after becoming thor-

oughly familiar with this document and other

publications regarding this equipment.

This equipment is not intended to protect hu-

man life.

Can cause death, severe personal injury, and/or equipment

damage

Follow all locally approved procedures and safety practices

when installing or operating this equipment.

Do not place the recloser in service until all

settings have been programmed and verified.

Failure to comply can result in recloser misoperation,

equipment damage, and personal injury.

Refer to sections 6 and 7 of this manual for control

programming and operation.

Handle position does not indicate de-

energized recloser enclosure controls

or circuit.

Contact with these components will cause severe

personal injury, death, or property damage.

Before contacting or servicing the equipment,

or working on the electrical system, isolate and

ground the recloser from the electrical system.

Verify recloser is de-energized by testing with

properly rated hot sticks and/or rubber gloves

and volt meter.

Safety Information

!

DANGER

!

DANGER

!

DANGER

!

CAUTION