FG2_MANUAL-en_R8(2016-08-11)ID70199.doc

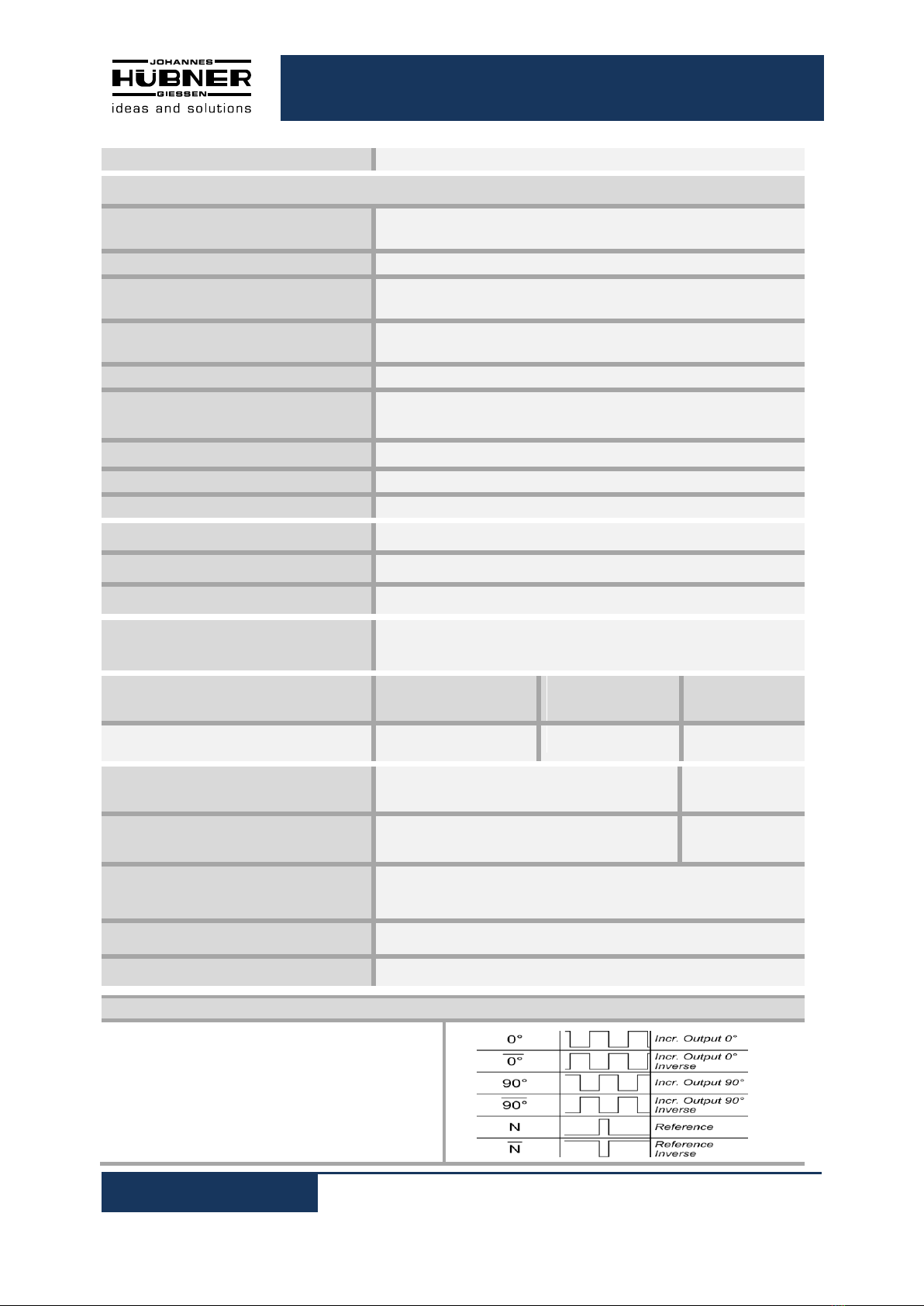

Directory

1General............................................................................................................................ 5

1.1 Information about the Operating and Assembly Instructions....................................... 5

1.2 Scope of delivery ....................................................................................................... 5

1.3 Explanation of symbols.............................................................................................. 5

1.4 Disclaimer.................................................................................................................. 6

1.5 Copyright ................................................................................................................... 6

1.6 Guarantee terms........................................................................................................ 6

1.7 Customer service....................................................................................................... 6

2Safety............................................................................................................................... 6

2.1 Responsibility of the owner ........................................................................................ 6

2.2 Personnel................................................................................................................... 6

2.3 Intended use.............................................................................................................. 7

2.4 Improper use.............................................................................................................. 7

2.5 Personal protective equipment................................................................................... 7

2.6 Special dangers......................................................................................................... 8

2.6.1 Electrical current.................................................................................................... 8

2.6.2 Rotating shafts / hot surfaces................................................................................ 8

2.6.3 Safeguarding against restart.................................................................................. 8

3Technical Data ................................................................................................................ 9

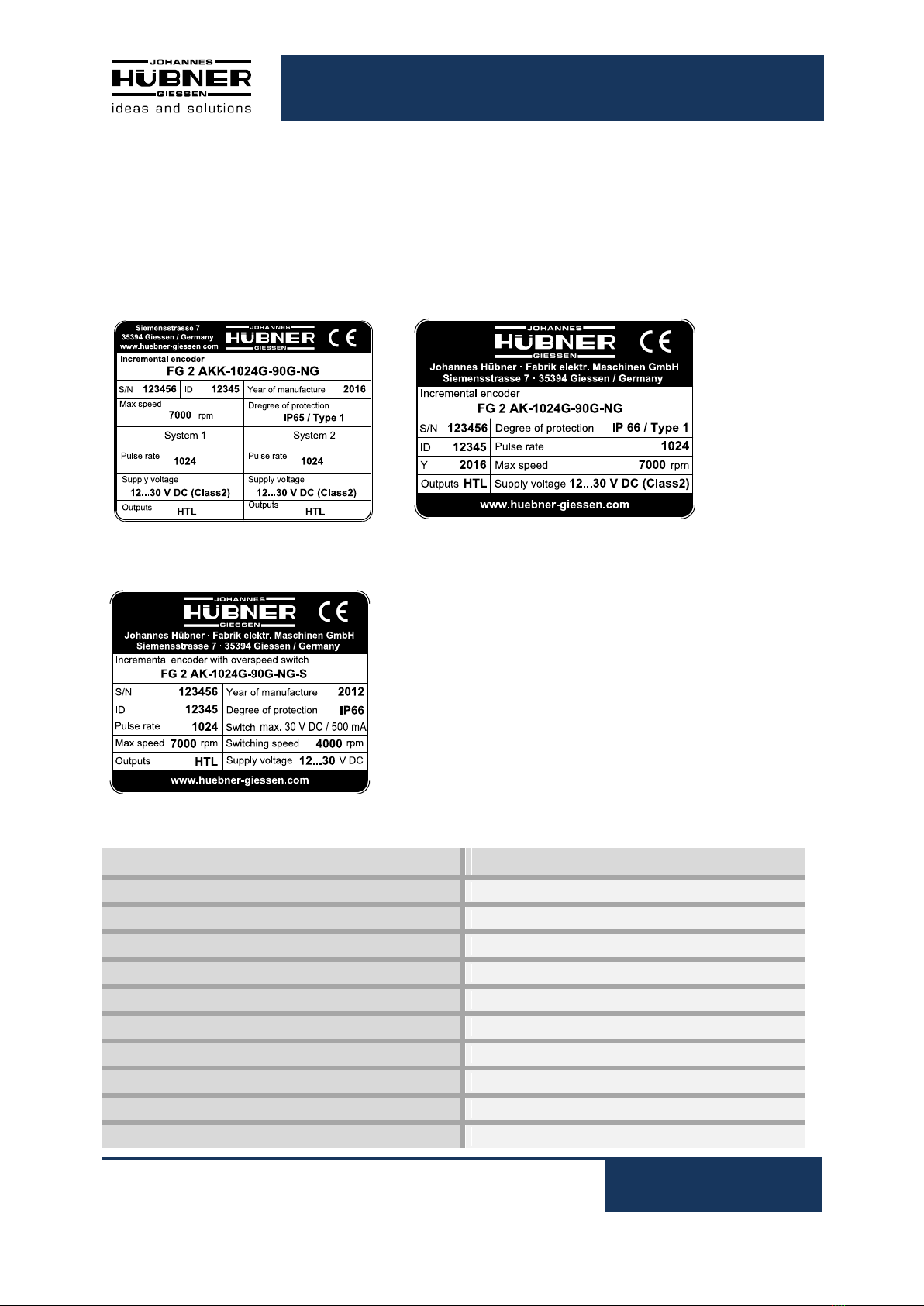

3.1 Type plate.................................................................................................................. 9

3.2 Electrical and mechanical data..................................................................................10

4Overview additional options .........................................................................................11

4.1 Option S (overspeed switch).....................................................................................11

4.2 Option LWL (signal transmission using fiber optics)..................................................11

4.3 Option AKK (double pulse output).............................................................................11

4.4 Type code.................................................................................................................12

5Transport, packaging and storage ...............................................................................13

5.1 Safety instructions for transport.................................................................................13

5.2 Goods inward inspection...........................................................................................13

5.3 Packaging / disposal.................................................................................................13

5.4 Storage of packages (devices)..................................................................................13

6Installation and commissioning....................................................................................14

6.1 Safety instructions.....................................................................................................14

6.2 Technical information................................................................................................14

6.3 Required tools...........................................................................................................14

6.4 Mounting preparations ..............................................................................................15

6.5 Mounting the encoder ...............................................................................................15

6.6 Mounting tolerances..................................................................................................17