Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany

\\Fileserver\text\PLAY\Play Installation Instructions\Installation Instructions 2012-2013\4540_10-01-en-010.doc - 5 -

2 Datasheet: Mini M-Swing, Art. 4540-10

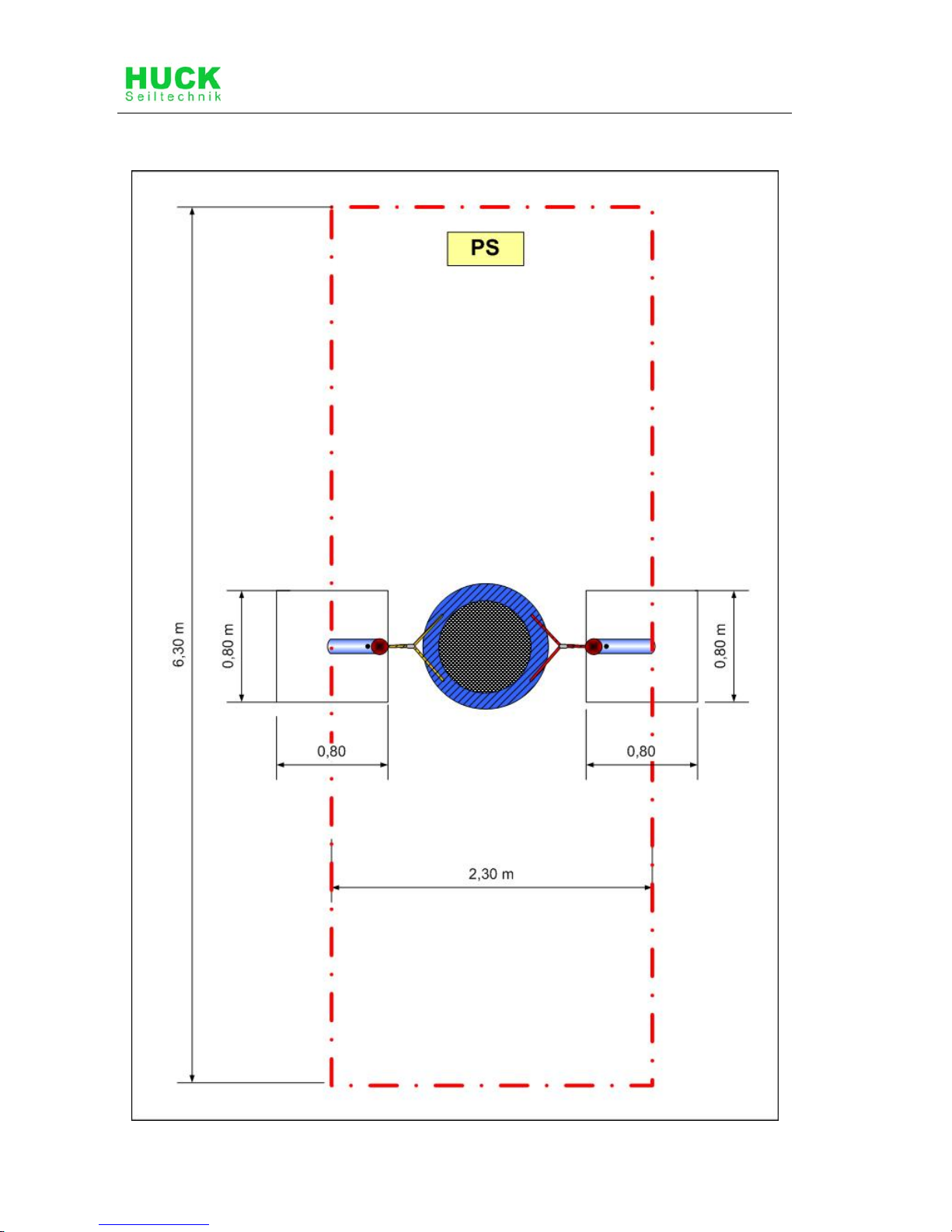

1. Space requirement: 3.00 m x 0.80 m and/or 2,30 m x 6,30 m including safety

zone, height of fall 1,45 m

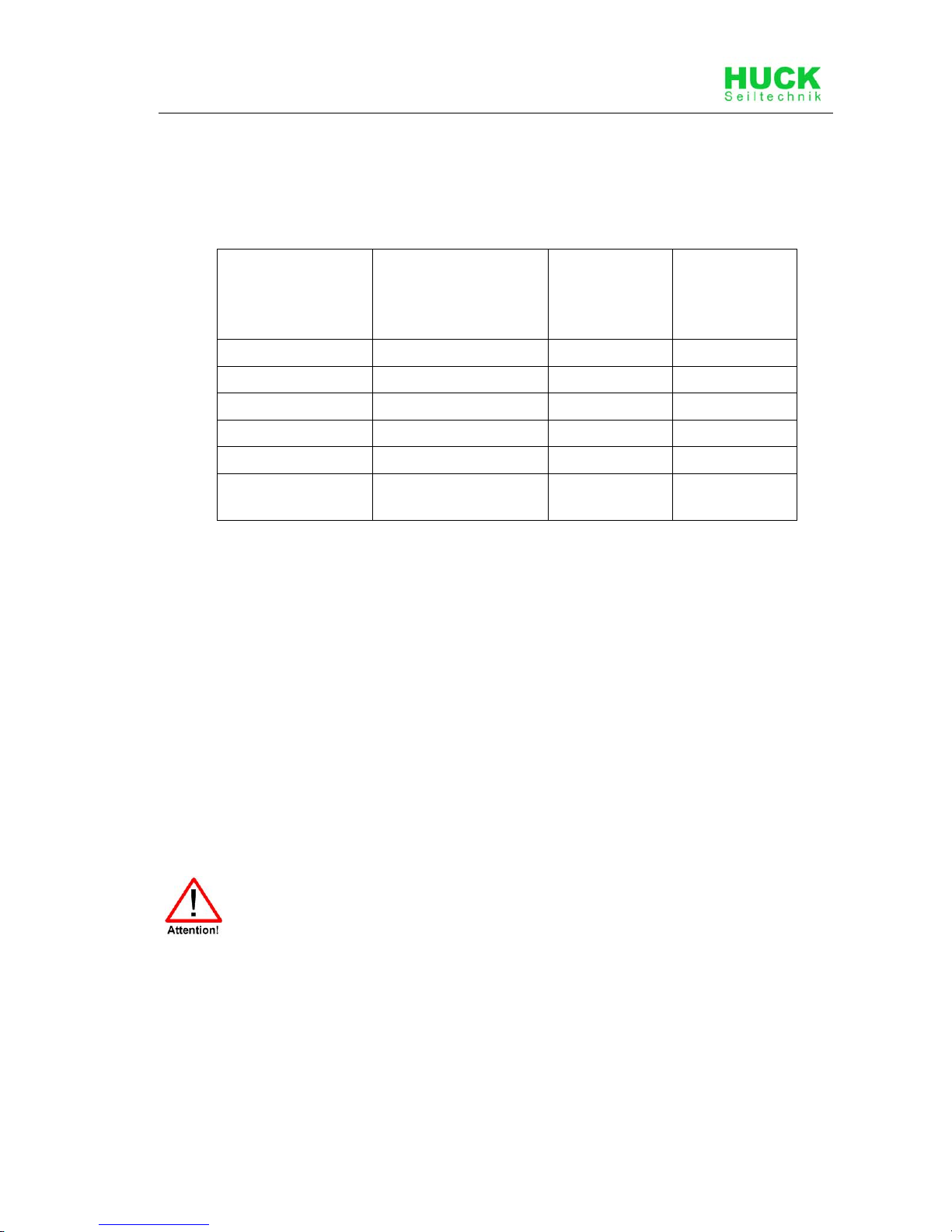

2. Required safety surface:

Surface material

Description

mm Minimum

thickness of

layer

mm

Maximum

height of fall

mm

Topsoil grass <= 1000*

Chipped bark 20 – 80 grain size 300/400 <= 2000/3000

Wood chippings 5 – 30 grain size 300/400 <= 2000/3000

Sand 0.2 – 2 grain size 300/400 <= 2000/3000

Gravel 2 – 8 grain size 300/400 <= 2000/3000

Other ground

materials As recommended by

manufacturer

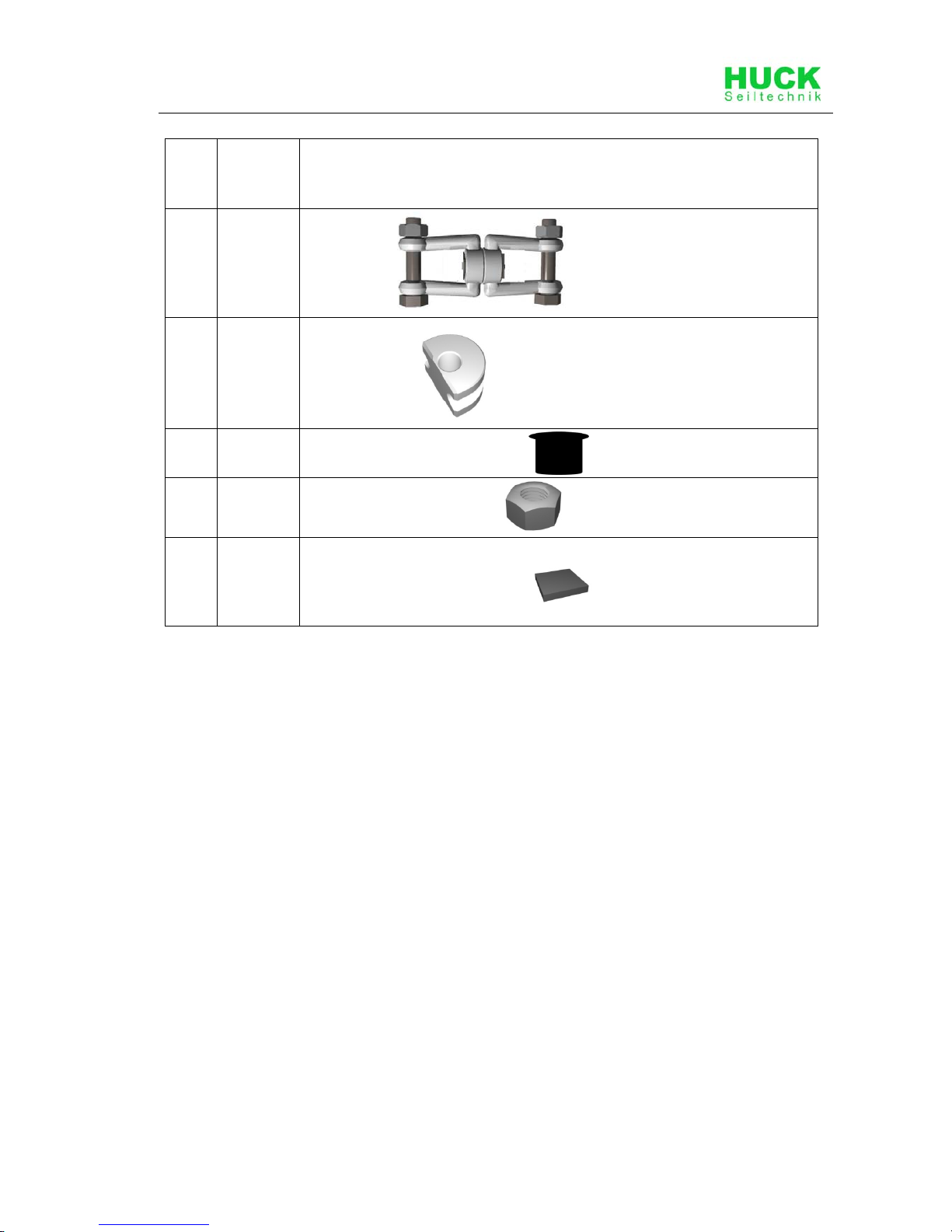

3. Name and overall dimension of the largest component:

Steel post (2 pieces) length 2.40 m, ø 100 mm

4. Name and weight of the heaviest component:

Steel posts (1 piece), approx. 18 kg

5. Intended age group: 2 years and over

6. Please note that this equipment is set in concrete.

Concrete: C25/30

Required concrete: 0.8 m3

Foundations/area to be excavated:

2 x 0.80 m long x 0.80 m wide, total depth 1.00 m including 10 cm drainage

Top edge of concrete 40 cm below ground level

Foundation size:

2 x 0,80 m long x 0,80 m wide, 0,60 m high

Round off foundation edges (min.R = 100 mm)! Sizes of fundations are “4-5”

(natural ground).

Soil class 4: soft to medium plasticity, interleave bound, with minor portion of

stone (portion < 30% with bigger diameter of 63 mm grain size).

Soil class 5 : ground with soil class 3 and 4 with big portion of stones

(portion > 30% with bigger diameter of 63 mm grain size).