HF01 manual v1622 5/27

Introduction

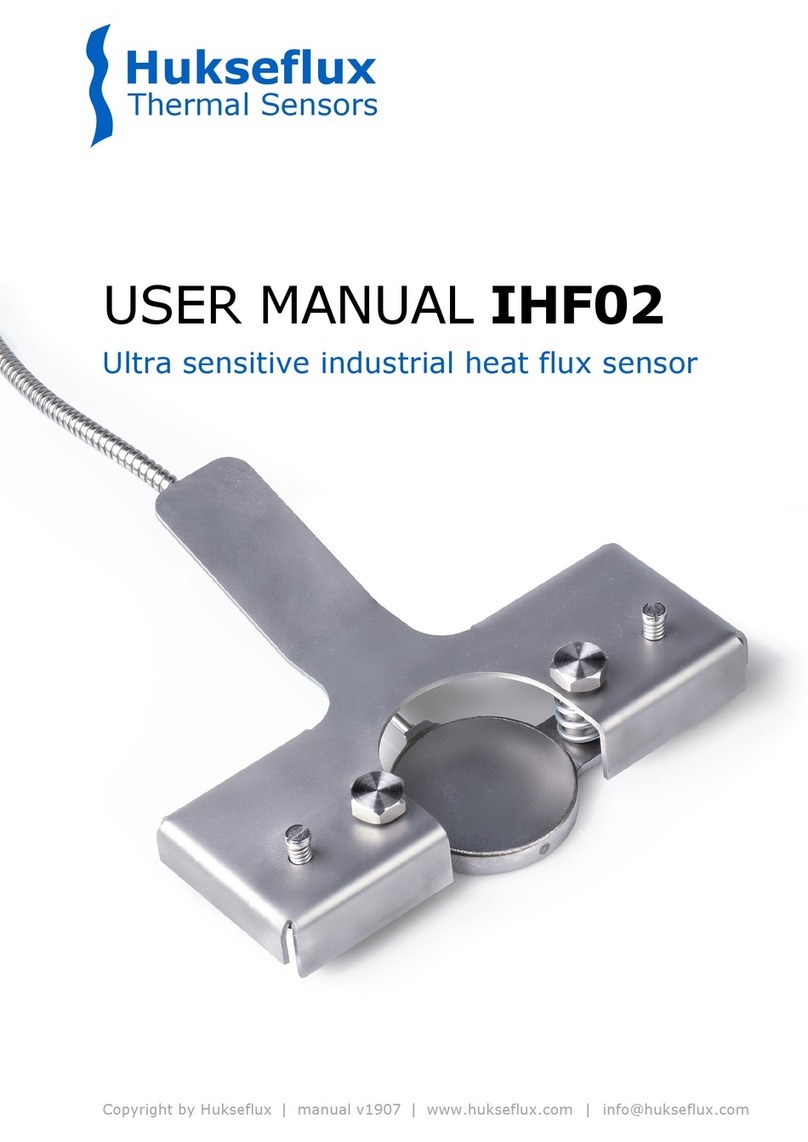

HF01 measures heat flux and surface temperature at high temperatures, typically in

industrial environments. It is particularly suitable for trend-monitoring and comparative

testing. HF01 measures heat flux and surface temperature of industrial furnaces, boilers,

fluidised beds, distillation columns and ovens. The sensors inside HF01, a thermopile and

a thermocouple, are protected by fully sealed stainless steel body. It is suitable for long

term use at one location as well as repeated installation when a measuring system is

used at multiple locations.

HF01 measures heat flux through the object on which it is mounted, in W/m2, as well as

its surface temperature in °C. The sensors in HF01 are a thermopile and a type K

thermocouple. The thermopile measures the temperature difference across the body of

HF01, creating an output that is representative of the local heat flux. The thermocouple

measures the absolute temperature of the surface on which HF01 is mounted, as well as

the approximate sensor body temperature. A thermopile and a thermocouple are passive

sensors; they do not require power.

The part of the cabling closest to the sensor is a special high-temperature metal

sheathed cable with an interlocked spiral stainless steel armour. The sensor as well as

the high temperature cable and armour withstand temperatures up to 800 °C.

The temperature range is reduced to 600 °C in case the black coating is used, to 550 °C

in case the frame with magnets is used.

To avoid leakage of current, a risk in aluminium reduction cells, a silicone sleeve is

placed over the metal armour. The low-temperature extension cable has wire insulation

and a jacket of PTFE type plastic. One face of HF01 is painted black, the other is blank

metal.

Using HF01 is easy. It can be connected directly to commonly used data logging systems.

The heat flux, Φ, in W/m2, is calculated by dividing the HF01 output, a small voltage U,

by the sensitivity S, and by applying a linear correction based on the temperature

measurement involving the temperature dependence TD.

The measurement function of HF01 is:

Ф = U/(S∙(1 + TD∙(T - Treference))) (Formula 0.1)

The sensitivity and temperature dependence are provided with HF01 on its product

certificate.

Equipped with heavy duty cabling, and having a fully stainless steel casing so that

moisture does not penetrate the sensor, HF01 has proven to be very reliable. It survives

long-term outdoor installation and repeated installation using the frame with magnets.