IHF02 manual v1907 5/35

Introduction

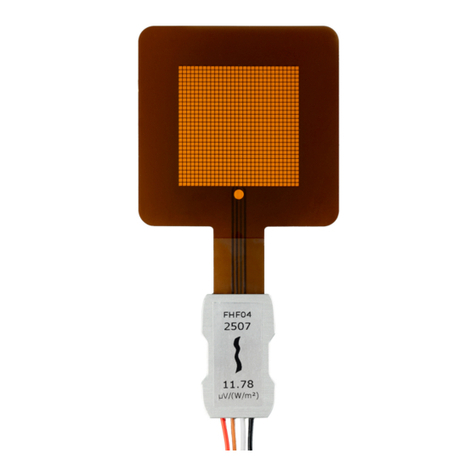

IHF02 ultra sensitive industrial heat flux sensor measures heat flux and temperature,

typically in industrial high-temperature environments. The instrument is waterproof,

withstands high pressures and is extremely robust. IHF02 is 25 times more sensitive

than model IHF01, making it suitable for use at relatively low heat flux levels. It replaces

model HF01 high temperature heat flux sensor. IHF02 complies with industrial safety

standards, such as CE and ATEX for explosive areas, and is particularly suitable for

trend-monitoring and comparative testing.

IHF02 measures heat flux and surface temperature of industrial equipment like furnaces,

boilers, fluidised beds, distillation columns and ovens. The sensors inside IHF02, a

thermopile and a type K thermocouple, are protected by a fully sealed stainless steel

body. It is suitable for long-term use at one location as well as surveys at multiple

locations. IHF02 measures heat flux through the object on which it is mounted, in W/m2,

as well as the temperature in °C. An optional magnet frame is offered for easy mounting

on magnetic surfaces.

IHF02 is 25 times more sensitive than model IHF01, so that, with the same

measurement accuracy of its output voltage, it can be used to measure much lower heat

flux levels. When equipped with the optional magnet frame and optional black coating,

IHF02 replaces model HF01 high temperature heat flux sensor.

Figure 0.1 IHF02 ultra sensitive industrial heat flux sensor