TP01 manual v1627 5/35

Introduction

TP01 is a sensor for long-term monitoring of soil thermal conductivity. A measurement

with TP01 may also be used to estimate the soil thermal diffusivity and volumic heat

capacity, leading to a better understanding of dynamic (variable heat flux) thermal

behaviour of soils. TP01 is designed for long-term use at one measurement location.

Applied in meteorological surface flux measurement systems, TP01 improves the

estimates of soil heat flux and of the so-called storage term (see the paragraph about

the storage term). The sensor, combining a heater and a temperature-difference sensor

with a high sensitivity and an extremely low thermal mass, is a proprietary Hukseflux

design.

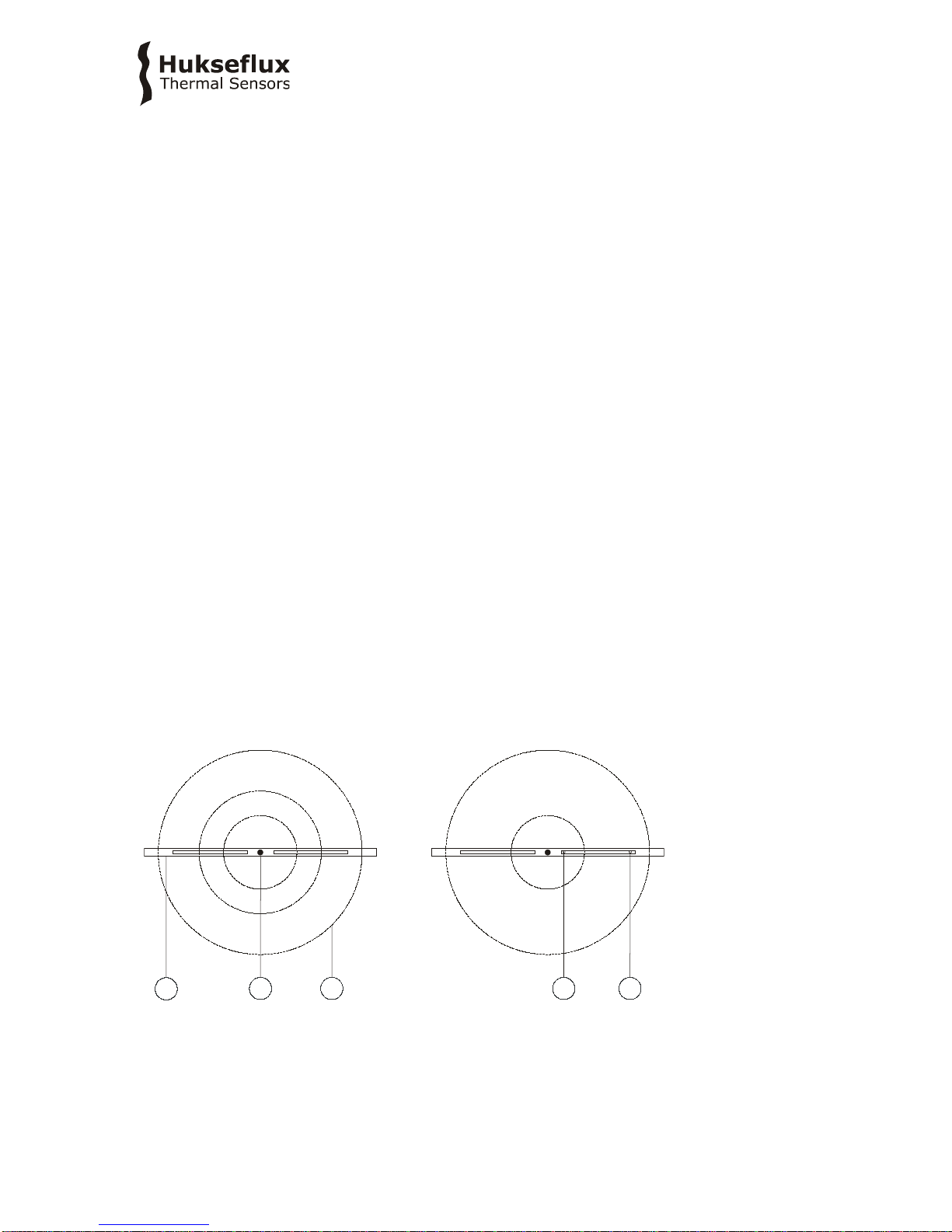

The sensor inside TP01 is a temperature-difference sensor consisting of 2 thermopiles. It

measures the radial temperature difference around a heating wire with a record breaking

sensitivity. Both the heating wire and the sensor are incorporated in a very thin plastic

foil.

TP01 measures soil thermal conductivity. It is designed for long-term on-site operation,

buried in the soil. Its rated operating range is 0.3 to 4 W/(m∙K), which covers most

inorganic soil types. The low thermal mass of TP01 also makes it suitable for measuring

the soil thermal diffusivity and the volumic heat capacity.

The thermal conductivity, λ, in W/(m·K), is calculated by dividing the TP01 sensitivity, S,

by the sensor output, a small voltage difference ΔU which is a response to stepwise

heating, and multiplying by the applied electrical power Q per meter heating wire.

The measurement function of TP01 is:

λ = S·Q/ ΔU (Formula 0.1)

The factory-determined sensitivity S,as obtained under calibration reference conditions,

is provided with TP01 on its product certificate. TP01 calibration is traceable to

international standards. The recommended calibration interval of TP01 is 2 years.

Thermal diffusivity and volumic heat capacity are estimated from time response to

stepwise heating. These measurements are optional.

The volumic heat capacity is a linear function of soil water content and you may use TP01

measurements to monitor trends in soil water content. Contrary to many other soil water

content sensors, TP01 is not sensitive to contamination by salts and the measurement

still functions in electrically conducting saline or fertilised soils.

TP01 should be incorporated in the user's measurement and control system. It can be

connected directly to commonly used data logging systems. Typically every 6 hours, the

TP01 heater is switched on to perform a measurement.

A typical TP01 is part of a meteorological surface flux measurement system in which also

wind, humidity, soil heat flux, soil temperatures at different depths and net-radiation are