Hukseflux Thermal Sensors

HFP01/ HFP03 manual version 0612 page 4/35

Introduction

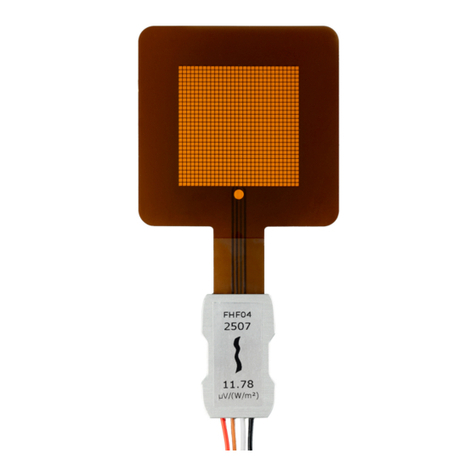

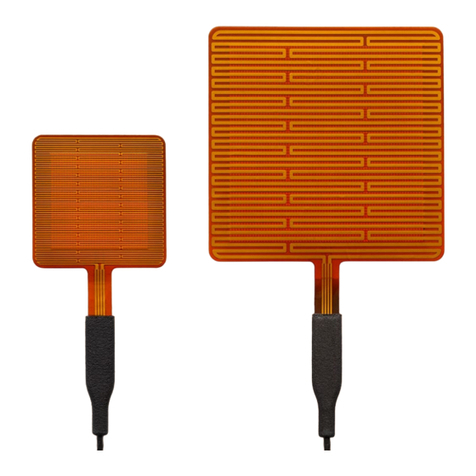

HFP01 is the world’s most popular sensor for heat flux

measurement in the soil and through walls and building

envelopes. By using a ceramics-plastic composite body the total

thermal resistance is kept small.

HFP01 serves to measure the heat that flows through the object

in which it is incorporated or on which it is mounted. The actual

sensor in HFP01 is a thermopile. This thermopile measures the

differential temperature across the ceramics-plastic composite

body of HFP01. Working completely passive, HFP01 generates a

small output voltage proportional to the local heat flux.

Using HFP01 is easy. For readout one only needs an accurate

voltmeter that works in the millivolt range. To calculate the heat

flux, the voltage must be divided by the sensitivity; a constant

that is supplied with each individual instrument.

HFP01 can be used for in-situ measurement of building envelope

thermal resistance (R-value) and thermal transmittance (H-

value) according to ISO 9869, ASTM C1046 and ASTM 1155

standards.

Traceability of calibration is to the “guarded hot plate” of

National Physical Laboratory (NPL) of the UK, according to ISO

8302 and ASTM C177.

A typical measurement location is equipped with 2 sensors for

good spatial averaging. If necessary two sensors can be put in

series, creating a single output signal.

If measuring in soil, in case a more accurate measurement is

needed the model HFP01SC should be considered.

In case a more sensitive measurement is required, model HFP03

should be considered.

In case of special requirements, like high temperature limits,

smaller size or flexibility the PU series could offer a solution.

This manual can also be used for HFP03. Differences between

HFP03 and HFP01 are highlighted in a special appendix on

HFP03.