FHF04SC manual v2101 10/41

1.3 Quick instrument check

A quick test of the instrument can be done by connecting it to a multimeter.

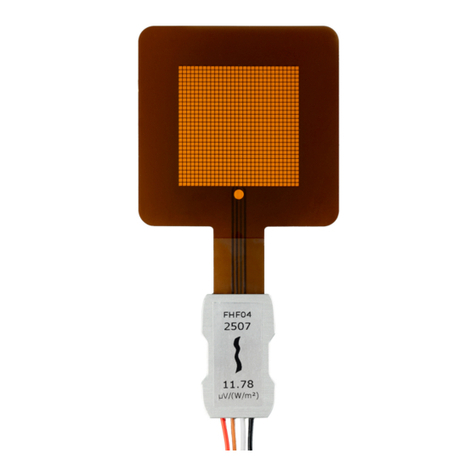

1. Check the sensor serial number and sensitivity on the sticker on the metal connection

block against the product certificate provided with the sensor.

2. Inspect the instrument for any damage.

3. Check the electrical resistance of the sensor between the red [+] and black [-] wires.

Use a multimeter at the 1k Ω range. Measure the sensor resistance first with one

polarity, then reverse the polarity. Take the average value. The typical resistance of the

wiring is 0.1 Ω/m. Typical resistance should be the nominal sensor resistance of 200 Ω

plus 0.2 Ω for the total resistance of two wires (back and forth) for each m. Infinite

resistance indicates a broken circuit; zero or a lower than 1 Ω resistance indicates a short

circuit.

4. Check the electrical resistance of the thermocouple between the brown [+] and white

[-] wires. Use a multimeter at the 100 Ω range. Measure the thermocouple resistance

first with one polarity, then reverse the polarity. Take the average value. The typical

resistance of the copper wiring is 0.1 Ω/m, for the constantan wiring this is 2.5 Ω/m.

Typical resistance should be the nominal thermocouple resistance of 2.5 Ω plus 2.6 Ωfor

the total resistance of the two wires (back and forth) of each m. Infinite resistance

indicates a broken circuit; zero or a lower than 1 Ω resistance indicates a short circuit.

5. Check if the sensor reacts to heat: put the multimeter at its most sensitive range of

DC voltage measurement, typically the 100 x 10-3 VDC range or lower. Expose the sensor

to heat. Exposing the back side (the side wit the heater) to heat should generate a

positive signal between the red [+] and black [-] wires. Doing the same at the front side

(the side with the dot), reverses the sign of the output.

6. Check the electrical resistance of the heater between any of the yellow wires and any

of the grey wires. Use a multimeter at the 1 kΩ range. Typical resistance should be

around 100 Ω. Infinite resistance indicates a broken circuit; zero or a lower than 1 Ω

resistance indicates a short circuit.

7. Check the electrical resistance between the 2 yellow wires and the 2 brown wires.

These resistances should be in the 0.1 Ω/m range, so 0.2 Ω in case of the standard 2 m

wire length.