7.

Maintenance

and

Troubleshooting

7.

1

Maintenance

...............................................

7-1

7.1.1

Source

Larnp

•.......................................

7-1

...__,

7.1.2

Incident

Beam

Optics

...............................

7-2

7.1.3

Photodetector

Temperature

..........................

7-3

7.

2

Diagnostics

....

...........................................

7-4

7.

2.

1

7.

2.

2

7.

2.

3

7.2.4

7.

2.

5

Lamp

..

.............................................

7-4

Lamp

Adjustment

....................................

7-5

A/D

Count

..........................................

7-6

PROM

CRC

.

..........................................

7-7

RAM

.....•.•.•....•....•.•.•...•..••••••..•.....•.••

7- 7

7.3

Error

Messages

............................................

7-8

7.

4

Troubleshooting

...........................................

7-9

7.4.1

Possible

Effects

of

Environment

....................

7-9

7.4.2

Failure

to

Initialize

..............................

7-10

7.4.3

General

Rules

for

Toubleshooting

...................

7-11

7.4.4

Symptoms Made

Evident

by

Digital

Readout

...........

7-12

7.4.5

Symptoms

Involving

Calibration

Errors

..............

7-14

8.

Warranty

and

Service

8.1

Warranty

..................................................

8-1

8 . 2 C1

aims

....................................................

8- 1

8.

2.

1

8.

2.

2

8.

2.

3

Breakage

or

Damage

.................................

8-1

Shortage

.

..........................................

8-2

Incorrect

Shipment

.................................

8-3

8.3

Returns

...................................................

8-3

8.4

Service

...................................................

8-3

8.

4.

1

8.4.2

Return

of

Instrument

for

Repair

....................

8-3

.,__,

On-Site

Repair

.....................................

8-3

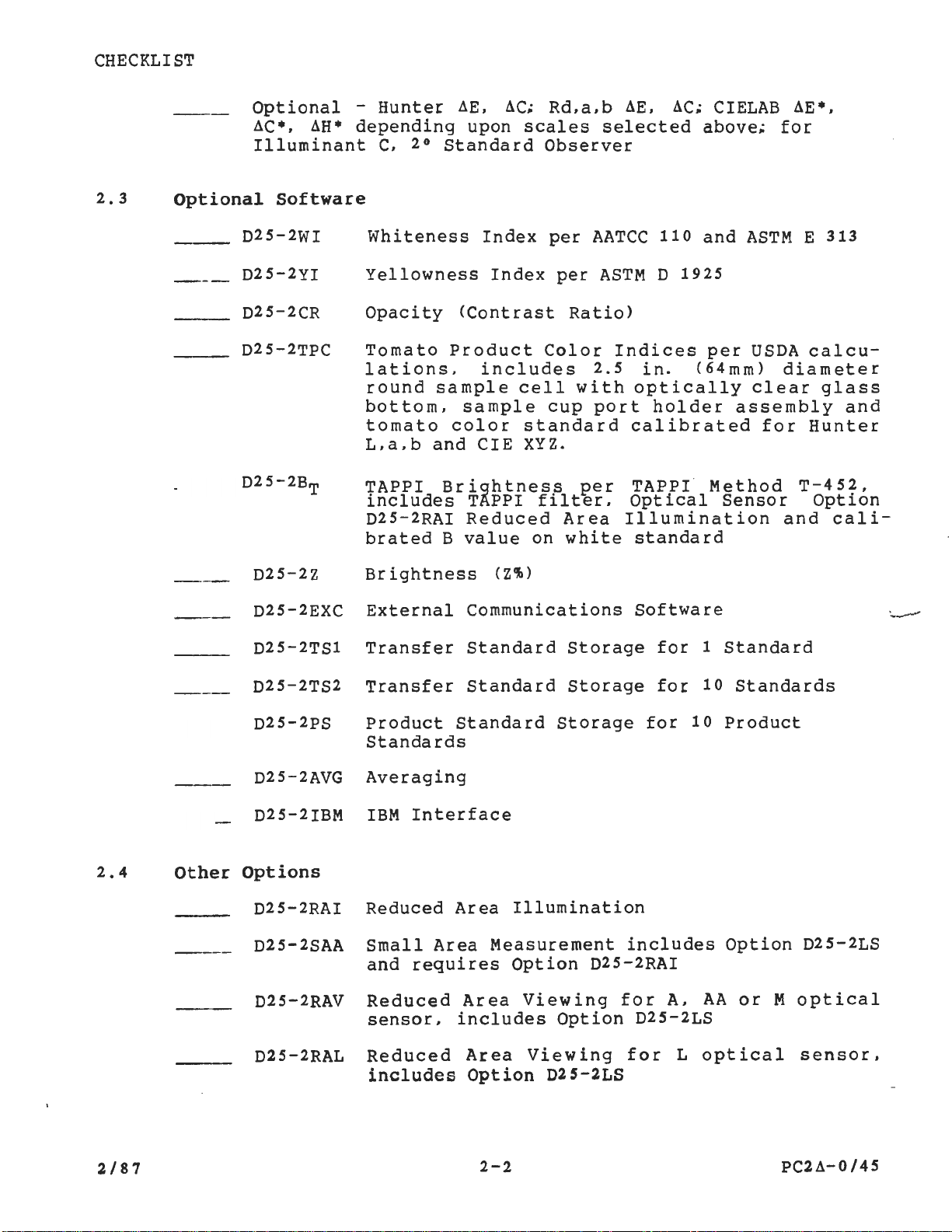

9.

Options

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

9.15

Reduced

Area

Illumination

and

Small

Area

Measurement

......

9-2

Reduced

Area

Viewing

......................................

9-4

L

Sensor

Reduced

Area

Viewing

.........

....................

9-5

Ultraviolet

Absorbing

Filter

..............................

9-6

Whiteness

Index

...........................................

9-7

Yellowness

Index

..........................................

9-9

Opacity

(Contrast

Ratio}

.................

.

................

9-11

Tomato

Product

Score

......................................

9-13

TAPP

I Br i g

ht

n

es

s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

-1

5

z-.,

Brightness

.

............................................

9-1

7

Transfer

Standardization

..................................

9-18

Averaging

.

................................................

9-21

Product

Standard

Storage

..................................

9-22

External

Communications

...............................

....

9-25

IBM

Interface

.............................................

9-27

10.

Appendix

10.1

Key

Function

Chart

.......•...............................

10-1

10.2

Pinout

Connections

.....•.................................

10-4

1o. 3

Reference

Material

.

......................................

10-5

INDEX

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com