2

Table of Contents

Table of Contents...............................................................2

Safety Information .............................................................2

Work Area Safety .....................................................................2

Personal Safety........................................................................2

Electrical Safety.......................................................................3

Fire Prevention.........................................................................2

Use and Care............................................................................2

Arc Welding..............................................................................3

Warranty ...........................................................................3

3 Year Limited Warranty ..........................................................3

Pre-Operation ................................................................... 4

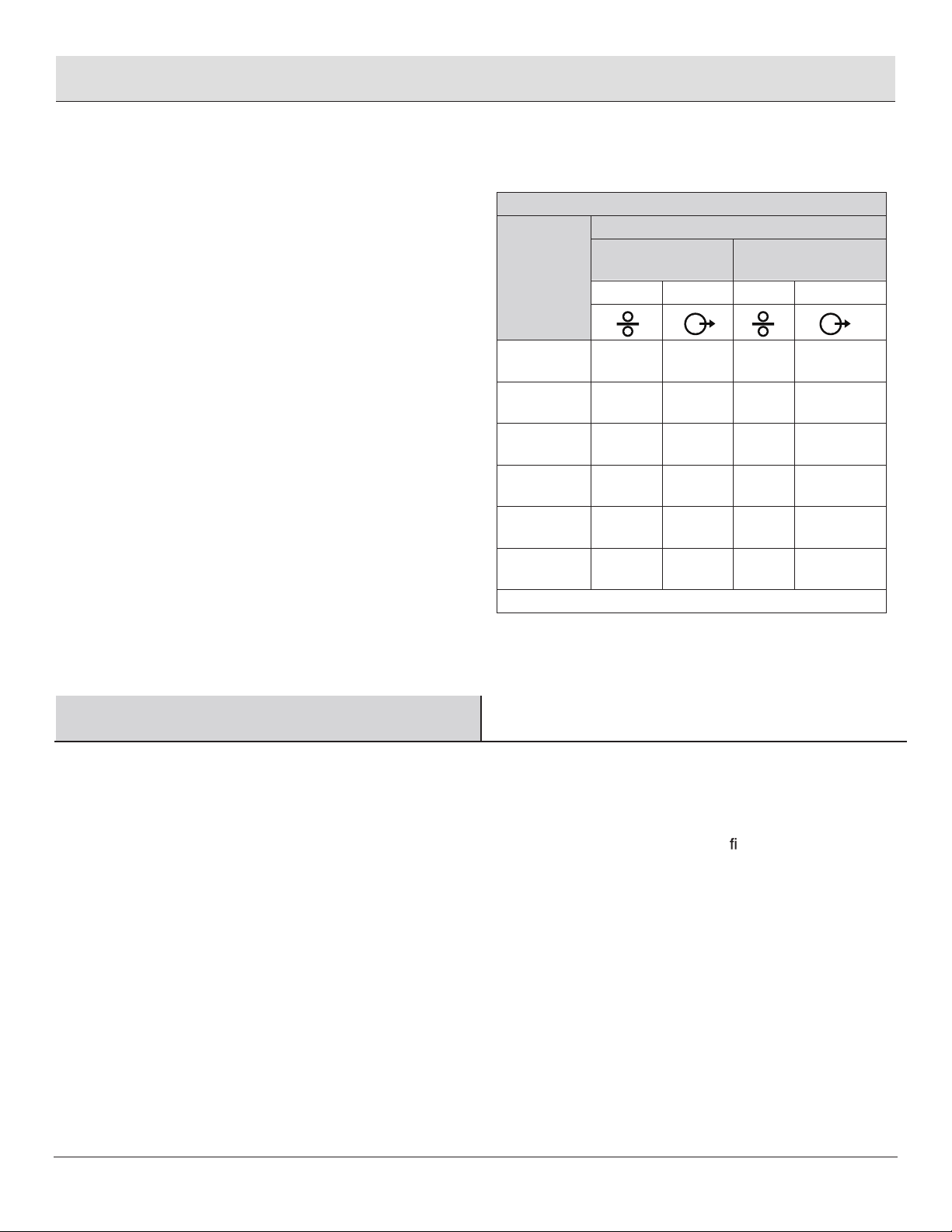

Speci ations ..........................................................................4

Package Contents ....................................................................5

Operation Instruction......................................................... 6

Maintenance ..................................................................... 8

Troubleshooting ................................................................ 9

Service Parts .................................................................. 11

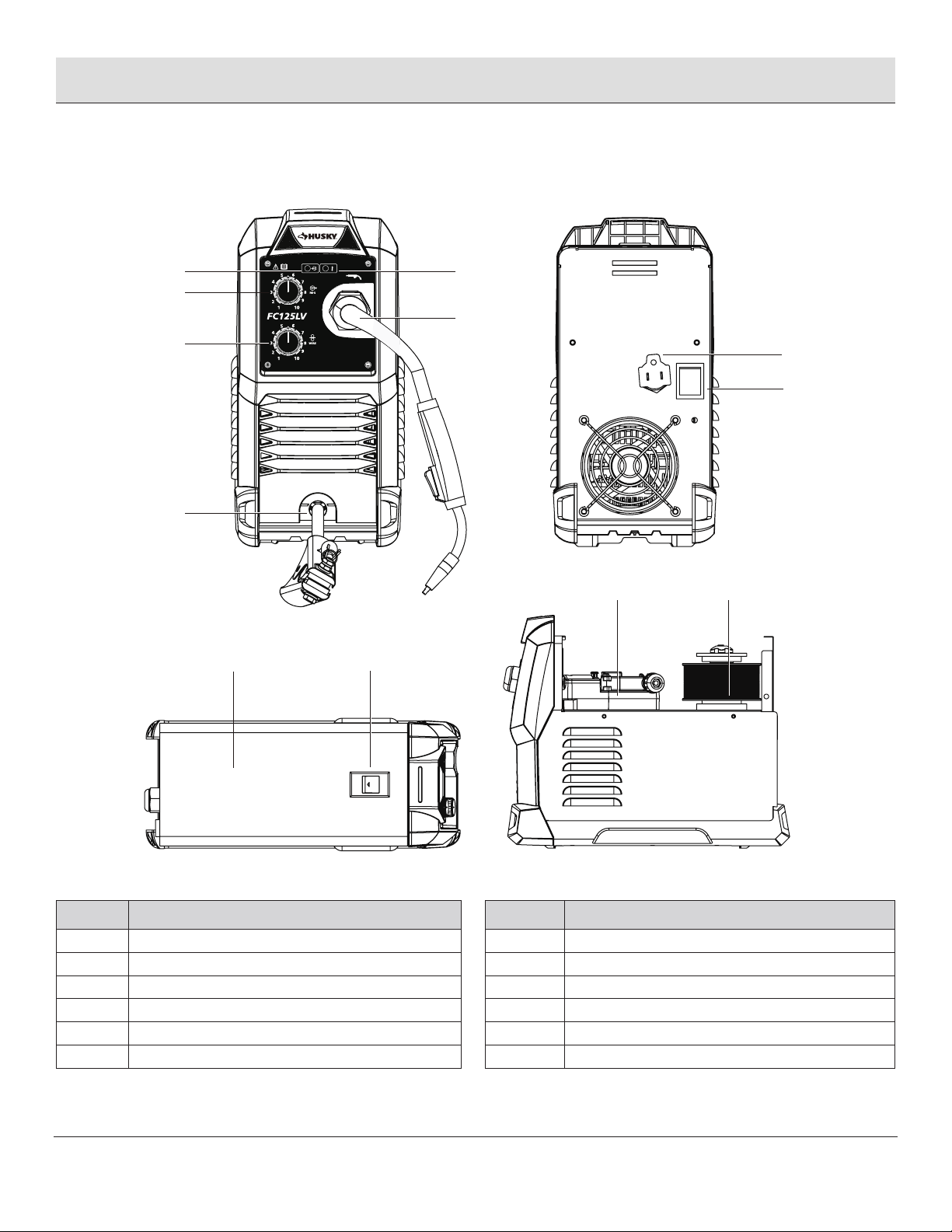

Assembly Diagram.................................................................11

Safety Information

WORK AREA SAFETY

WARNING: Operating the welding machine without

preparation and caution can cause death, injury to yourself

or bystanders. To reduce the risks, the operator should

read, understand and follow the safety instructions.

Besides, bystanders in the area should also follow the

safety instructions under the guidance of operator.

□Ensure your work area is clean and well lit.

□Keep the welder on a stable and clean surface while

operating.

□Keep children, bystanders and visitors away while operating

welding machine. Distractions can cause you to lose control.

□Do not operate machines in explosive atmospheres, such as

in the presence of ammable liquids, gases or dust. Flying

sparks during welding may ignite the dust or fumes.

□Do not leave energized machine unattended. Always turn off

the machine before servicing parts, replacing components

or when the machine is not in use.

PERSONAL SAFETY

WARNING: Welding processes generate high-temperature

arc, welding sparks, hot slag and hot spatters. Welding arc

generates extremely intense ultraviolet and infrared light.

Failure to wear protective equipment during welding can

severely damage your eyes and burn your skin. To reduce

the risks, the operator should read, understand and follow

the safety instructions. Bystanders in the area should also

follow the safety instructions under the guidance of

WARNING: Welding processes generate fumes, gases and

vapors which can cause discomfort, illness and death. To

reduce the risks, the operator should read, understand and

follow the safety instructions. Bystanders in the area should

also follow the safety instructions under the guidance of

□Do not weld without proper protection. Flying sparks can

cause burn injury. Always wear protective clothing and face

shield. The intensive light of the electrical arc can also burn

skin. Ensure to wear closed-toe shoes, gloves and clothing

with heavy material, long sleeves and collar.

□Do not look at an electric arc without proper eye protection.

An electric arc is extremely bright and intense which can

burn the eye retina and cause permanent damage when

equipped with inadequate or no eye protection.

□Do not weld in con ned areas without adequate

ventilation. Otherwise, wear an air-supplied respirator.