Safety

The definitions below give the level of severity for

each signal word.

Use the product correctly. Injury or death is a

possible result of incorrect use. Only use the

product for the tasks found in this manual. Do not

use the product for other tasks.

Obey the instructions in this manual. Obey the

safety symbols and the safety instructions. If the

operator does not obey the instructions and the

symbols, injury, damage or death is a possible result.

Do not discard this manual. Use the instructions

to assemble, to operate and to keep your product

in good condition. Use the instructions for correct

installation of attachments and accessories. Only

use attachment and accessories which are same

as original ones or supplied by Husqvarna or our

representative.

This manual cannot include all situations that can

occur when you use the product. Be careful and

use your common sense. Do not operate the

product or do maintenance on the product if you

are not sure about the situation. Speak to a

product

expert, your dealer, service agent or approved

service center for information.

Never use the machine if you are tired, if you

have drunk alcohol, or if you are taking

medication

that could affect your vision, your judgement or

your co-ordination.

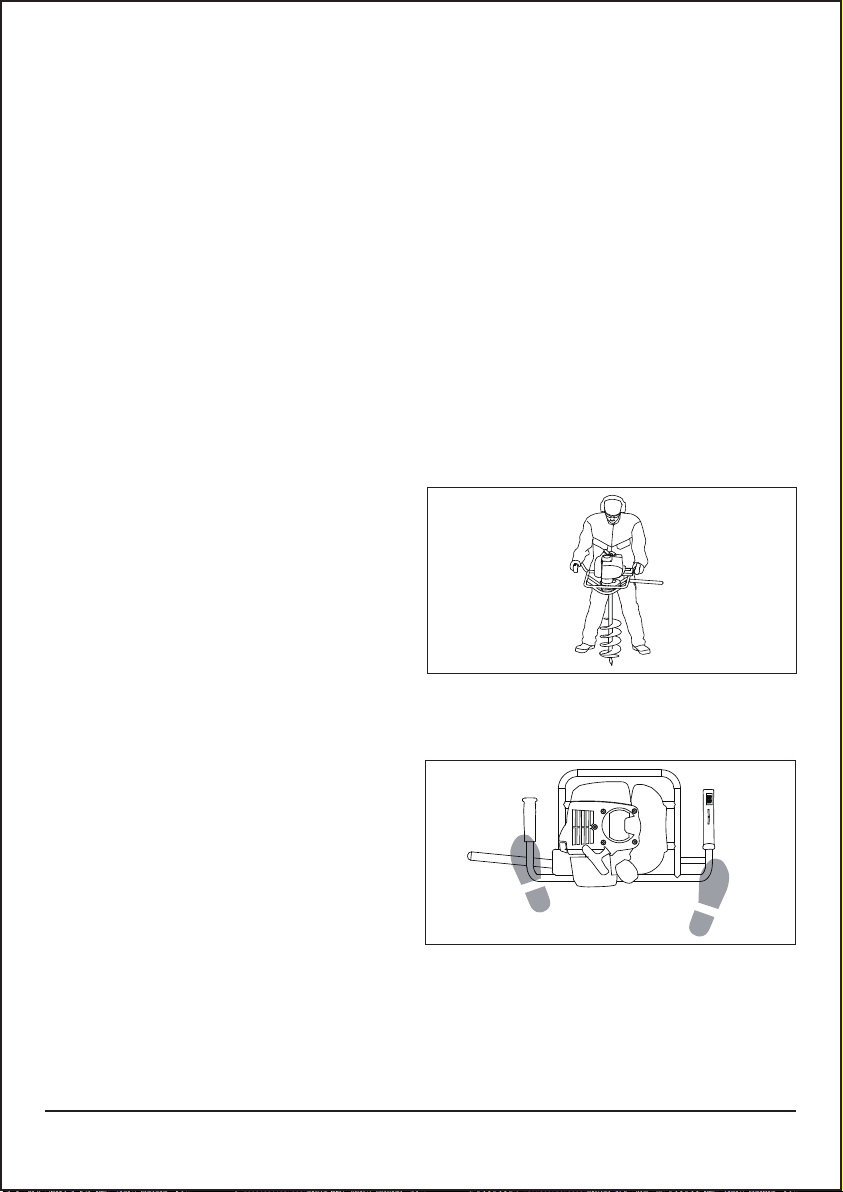

Wear personal protective equipment. See instructions

under the Personal protective equipment heading.

Never use a machine that is faulty. Carry out the

safety checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained

and qualified specialists. See instructions under

•

•

•

•

•

•

•

the Maintenance heading.

All covers and guards must be fitted before starting.

Ensure that the spark plug cap and ignition lead

are undamaged to avoid the risk of electric shock.

Ensure that no-one comes closer than 5 m while

you are working.

Carry out an overall inspection of the machine

before use. See the Maintenance schedule.

When you use this product the engine makes an

electromagnetic field. The electromagnetic field

can cause damage to medical implants. Speak to

your physician and medical implant manufacturer

before you operate the product.

Do not start the product indoors or near

flammable material. The exhaust fumes are hot

and can contain a spark which can start a fire.

Running an engine in a confined or badly

ventilated area can result in death due to

asphyxiation or carbon monoxide poisoning.

Do not let a child operate the product. Do not let

a person without knowledge of the instructions

operate the product.

Make sure that you always monitor a person,

with decreased physical capacity or mental

capacity, that uses the product. A responsible

adult must be there at all times.

•

•

•

•

•

•

•

•

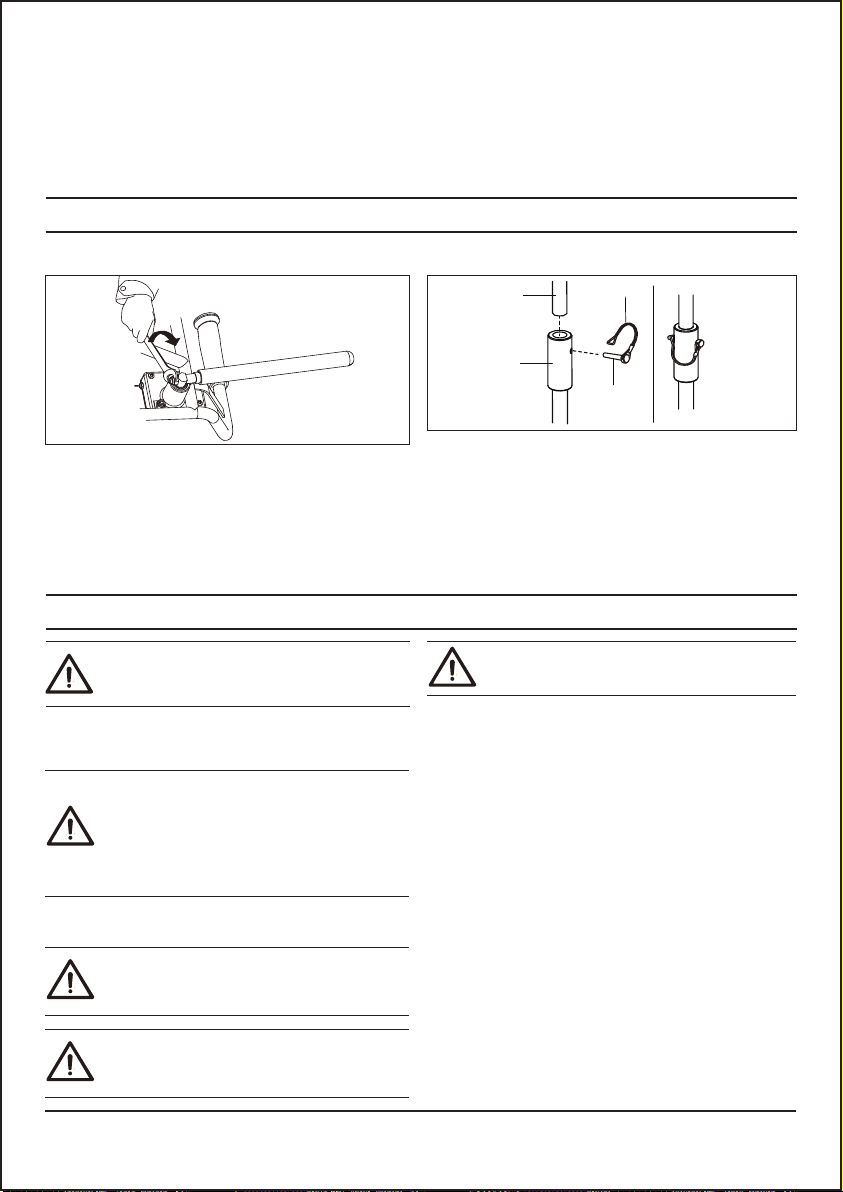

An earth auger is a dangerous tool if used

carelessly or incorrectly and can cause serious,

even fatal injuries. It is extremely important that

you read and understand the contents of this

Operator’s Manual.

Do not operate the product if there are persons

or animals in the work area. Stop the product if a

person or an animal goes into the work area. Do

not turn with the product before you make sure

that no persons or animals are in the safety area.

Make sure that you are always in control of the

product.

Do not use the product if you cannot receive aid

if an accident occurs. Always make sure others

know you will operate the product before you

start to operate the product.

Remove all unwanted materials from the work

area before you start. If the drilling attachment

hits an object, the object can eject and cause

injury or damage. Unwanted material can wind

around the drilling attachment and cause

damage.

•

•

•

•

•

Safety definitions

Safety instructions for operation

4

WARNING: Injury to persons.

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

CAUTION: Damage to the product.

Note:

This information makes the product easier to

use.