Metro™ Seating System – Assembly Instructions

Revision R, August 2021 3

Required for all applications:

• Tape Measure

• Pencil

• 6mm Hex Key (Allen Head style)

• Dead-Blow Hammer

• Ball Peen Hammer

TELESCOPIC METRO:

• 3/8 Hex Drive Socket

• Flat Head Screwdriver

• 5mm Hex Key (Allen Head style)

• 8mm Hex Key (Allen Head style)

• 16mm Open End Wrench

• 2 1/8” diameter Hole Saw

• 3/16” diameter drill bit

FIXED METRO:

• Rotary Hammer Drill

• Chop Saw & 100 tooth Carbide

Tipped Cutting Blade

• 1/4” Diameter Masonry Drill Bit

(Floor)

• 9/16” Diameter Masonry Drill Bit

(Riser)

• Setting Tool (Floor)

• Vacuum or Air Compressor to

clean holes

• Adhesive, Dispenser, Brush,

and Nozzle (Riser)

NOTE: Read these assembly

instructions carefully prior to

product installation. Product

failure and personal injury may

result if instructions are not

followed.

CONCRETE SPECIFICATION:

Minimum concrete compressive strength:

•Normal weight stone aggregate - 3000 PSI

•Light-weight aggregate - 5000 PSI

Minimum concrete thickness (riser mount):

•4 1/2” min. thickness with the first 3”, along the face, clear of

any obstructions (meshing, reinforcing bar, etc.)

NOTE:

Warranty is null and void if Hussey Seating product is installed on

floors or risers not meeting the minimum structural requirements

stated above.

TOOLS REQUIRED MINIMUM INSTALLATION CONTRUCTION (Fixed Metro)

INSTALLATION STEPS SUMMARY:

1. Read Assembly Instructions.

2. Review the job package drawings provided by Hussey Seating.

3. Verify field dimensions and floor / riser construction.

4. Utilize the shipping schedule to verify that all listed components are on site.

5. Layout Beams

6. Layout and Mechanisms or Fixed Supports.

7. Layout Unlock Bars

8. Install Beams

9. Drill decks (Auto-Fold only)

10. Attach Mechanisms

11. Install Unlock Bar Actuators

12. Install Trip Mechanisms (Auto-Fold only)

13. Install Armrests.

14. Install Dustcovers (telescopic only).

15. Install Tablet System (when applicable).

16. Install Chair Modules.

17. Install Chair Deflectors

18. Operate Chair Units (telescopic only).

19. Mechanism motion adjustment (telescopic only)

20. Beam End Cap Installation.

21. Seat Number, Row Letter and Donor Plate Installation.

22. Install ADA Compliant Armrests (fixed only).

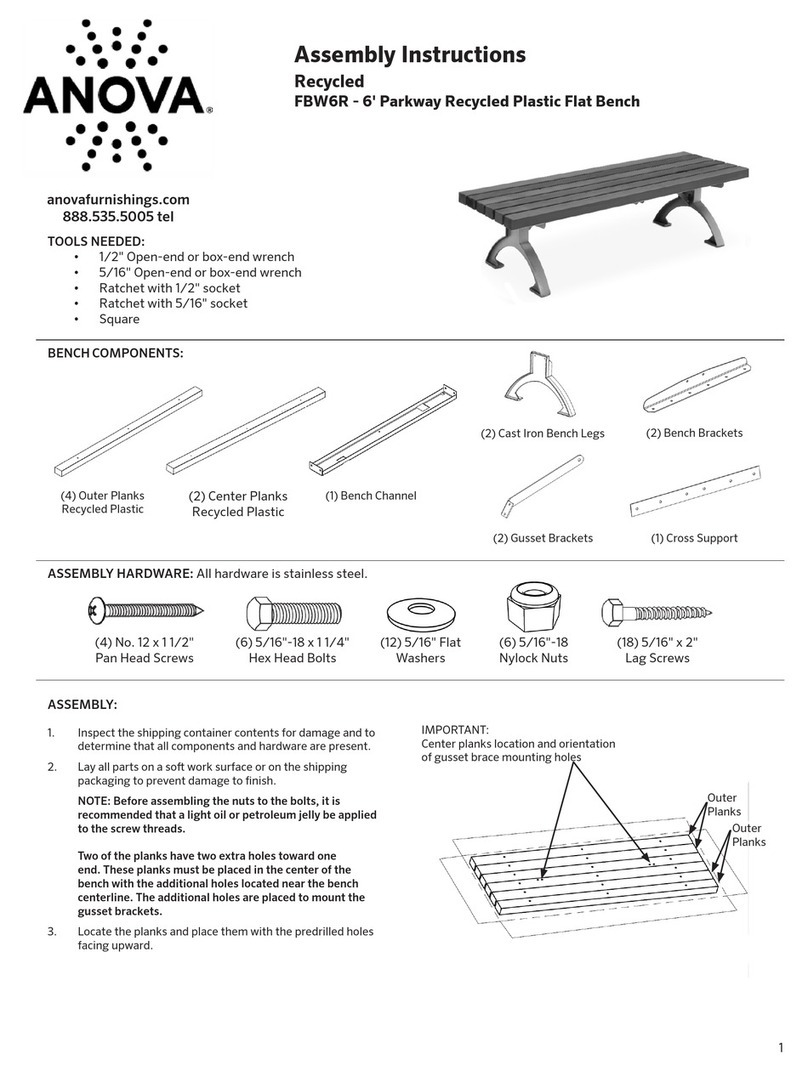

Assemble units as described. To do otherwise may

result in instability. All screws, nuts and bolts must

be tightened securely and must be checked

periodically after assembly.

Failure to assemble properly, or to secure parts

may result in assembly failure and potential injury.

Assemble units as described. To do otherwise may

result in instability. All screws, nuts and bolts must

be tightened securely and must be checked

periodically after assembly.

Failure to assemble properly, or to secure parts

may result in assembly failure and potential injury.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION