Rev. 0308

5

Plumbing

WASTE OUTLET AND P-TRAP

The waste outlet is located off the center of the case

on one side allowing drip piping to be run lengthwise

under the fixture.

A 1-1/2" P-trap and threaded adapter are supplied with

each fixture.The P-trap must be installed to prevent air

leakage and insect entrance into the fixture.

NOTE: PVC-DWV solvent cement is recommended.

Follow the manufacturer’s instructions.

INSTALLING CONDENSATE DRAIN

Poorly or improperly installed condensate drains can

seriously interfere with the operation of this re-

frigerator,and result in costly maintenance and product

losses.Please follow the recommendations listed below

when installing condensate drains to insure a proper

installation:

1. Neveruse pipeforcondensate drains smaller than

thenominal diameterof the pipe or P-trapsupplied

withthe case.

2. Whenconnecting condensatedrains,theP-trap

mustbeused aspartof the condensate drain to

preventairleakage or insect entrance.Store plumb-

ingsystem floordrains should be at least14" offthe

centerof thecase to allowuse of the P-trappipe

section.Never use twowater seals in series in any

oneline.DoubleP-trapsin series will cause alock

andpreventdraining.

3. Always provide as muchdownhillslope (“fall”) as

possible;1/8"perfootis the preferredminimum.

PVCpipe,whenused,mustbe supported tomain-

tainthe 1/8"pitch and to preventwarping.

4. Avoidlongruns ofcondensate drains.Longruns

make it impossible to providethe“fall” necessary for

gooddrainage.

5. Providea suitableair break betweenthe floodrim of

thefloor drain andoutlet ofcondensate drain. 1"is

ideal.

6. Preventcondensate drains fromfreezing:

a. Donot installcondensate drains in contact with

non-insulatedsuction lines. Suctionlines shouldbe

insulatedwith anonabsorbent insulation material

suchasArmstrong’sArmaflex.

b. Wherecondensate drains arelocated in deadair

spaces(betweenrefrigeratorsorbetweena

refrigeratorand a wall),providemeans to prevent

freezing.Thewater sealshould be insulated to

preventcondensation.

Refrigeration

GELATO/SOFT ICE CREAM

These display cases are designed to hold product at

temperatures that will allow operators to scoop or dip

gelato and soft ice cream into cones,containers or

dishes.The temperatures will fall in the range of plus 4F

to plus 12F depending on amount of sugar and butterfat

in product.The temperature and condition of product

must be checked after being in case the first four hours

of operation.Because of the sensitive condition of these

products,defrost is very critical.The fans do NOT run

during defrost periods.The maximum time is 20

minutes for electric and 10 minutes for hot gas and

Kool Gas.The fans are on a 2 minute delay after defrost

to avoid adding heat to case.

If,because of ambient conditions,the defrost must be

changed,amount of defrosts not time is necessary.i.e.,3

by 20 minutes instead of 2 x 40 minutes.

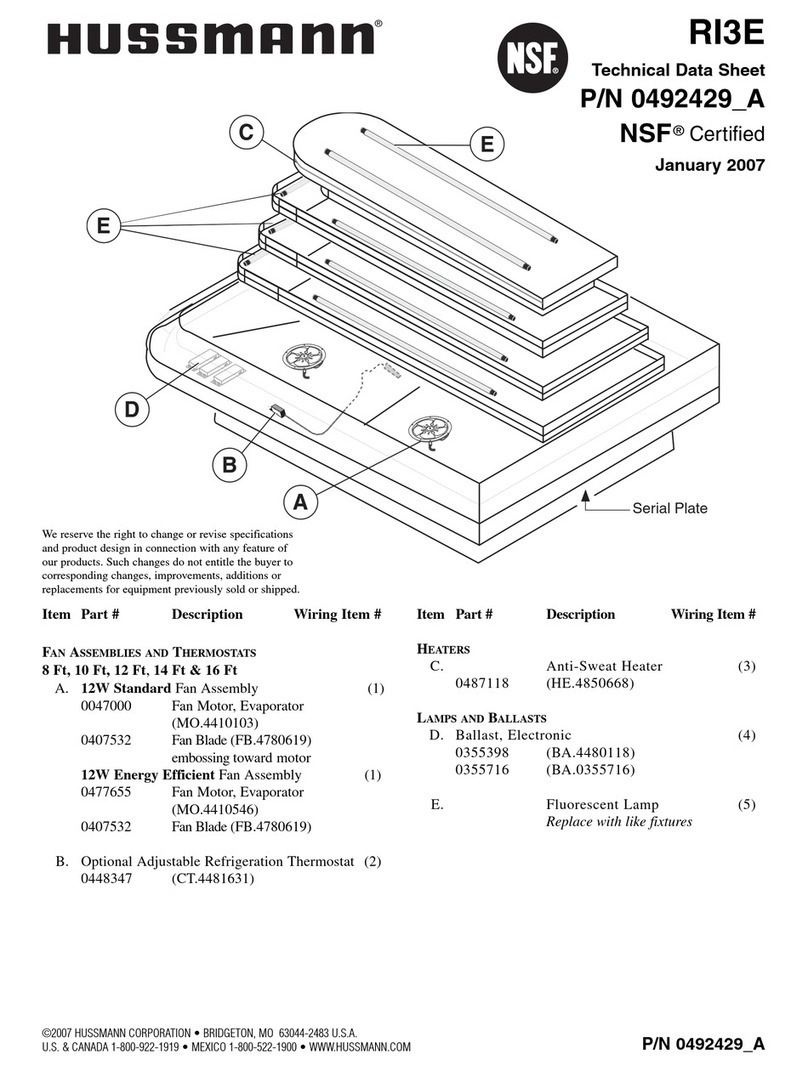

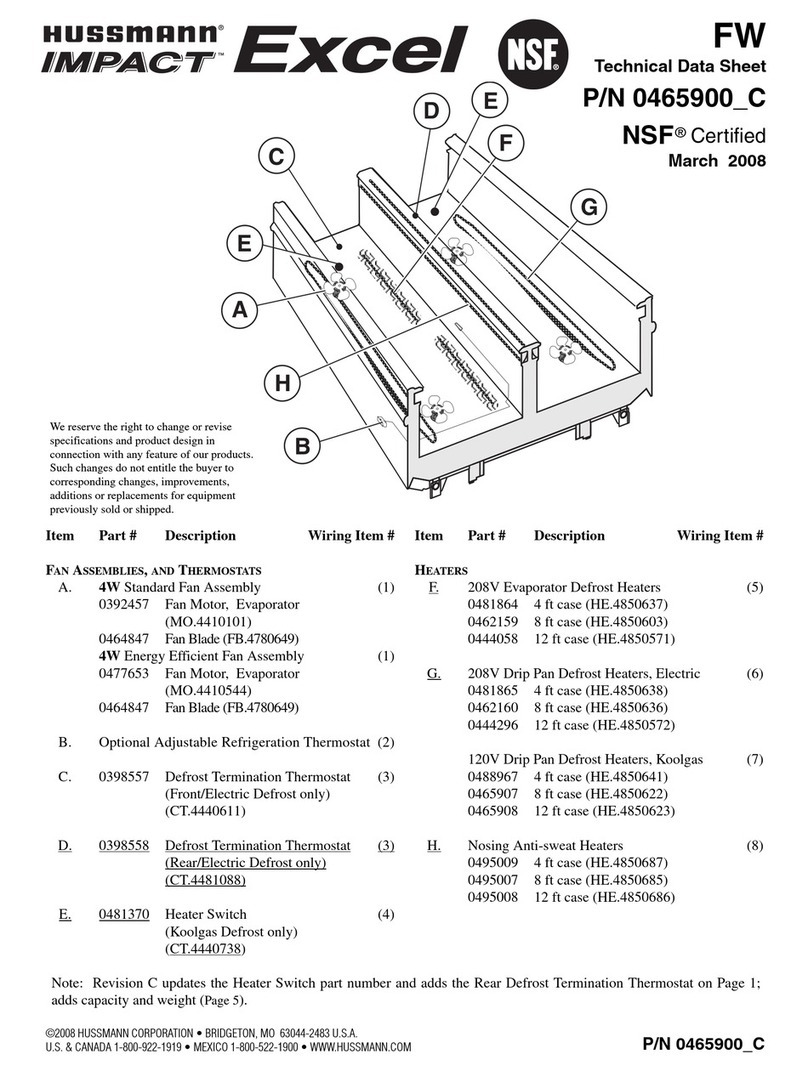

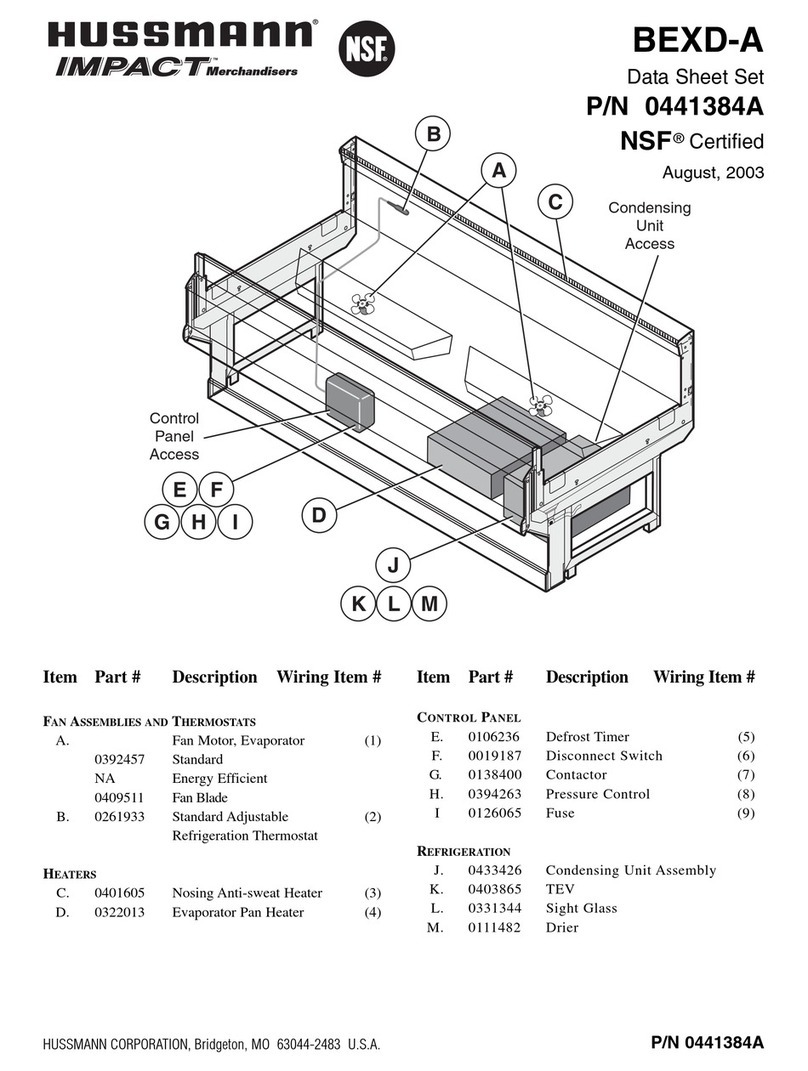

REFRIGERANTTYPE

The standard refrigerant will be R-404 unless otherwise

specified on the customer order.Check the serial plate

on the case for information.

Piping for more than one case on a condensing unit is

run underground with either common suction and

liquid lines from the machine room or individual suction

and liquid lines joined together in the machine room.

REFRIGERATION LINES

LIQUID SUCTION

3/8" O.D. 5/8" O.D.

NOTE: The standard coil is piped at 5/8" (suction); however,

the store tie-in may vary depending on the number of

coils and the draw the case has. Depending on the case

setup, the connecting point in the store may be

5/8", 7/8", or 11/8". Refer to the particular case you are

hooking up.

Refrigerant lines should be sized as shown on the

refrigeration legend furnished by the store.

Install P-traps (oil traps) at the base of all suction line

vertical risers.

Pressure drop can rob the system of capacity.To keep the

pressure drop to a minimum,keep refrigerant line run

as short as possible,using the minimum number of

elbows.Where elbows are required,use long radius

elbows only.

FOR REFRIGERATORSWITH KOOLGAS DEFROST,