www.h-v-c.com

Operation and maintenance manual

NCA Series 100 - CE marked fire dampers

Upon receipt of unit - Before signing for the delivery

Flourescent yellow stickers are attached to every package we

despatch detailing receipt instructions and what to do if your goods

are damaged.

The instructions on this must be followed or HVC will not be able to

assist with any claims for damage.

Prior to installation

If the damper is to be stored on site, ensure it is stored in a clean

and dry environment.

Immediately prior to fitment, remove all packaging from the unit.

Take particular care inspecting the inside of the unit for any

packing materials which may disrupt damper operation.

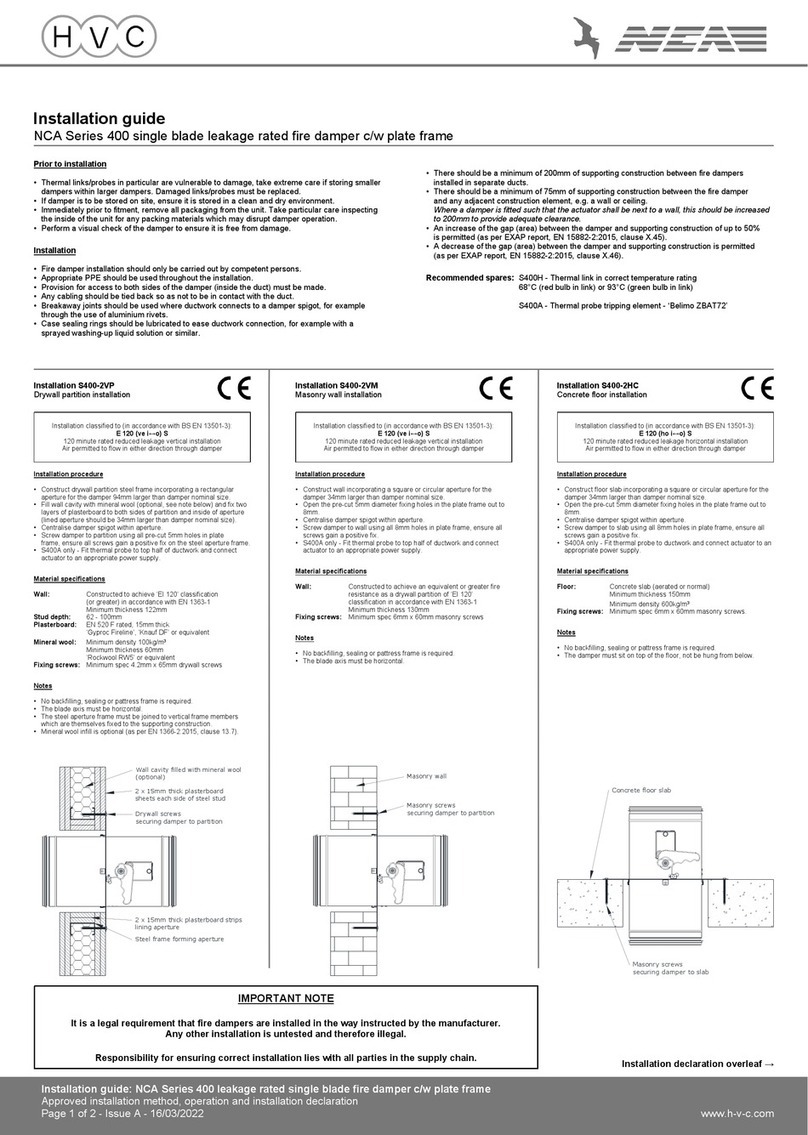

Installation

All fire damper installations must be carried out as stated by HVC.

Installation instructions are available to download at:

www.h-v-c.com/installations

Installation should only be carried out by competent persons. Fire

dampers are life safety devices, their effectiveness is reliant on

correct installation.

Damper edges can be sharp. The relevant PPE should be used

when handling dampers, in accordance with the relevant local risk

assessment/s.

Larger dampers can be very heavy, ensure suitable lifting methods

are used to help prevent injury.

Ensure that ductwork is appropriately supported, and that the

damper itself will not be relied upon to support ductwork.

Remove the safety cable tie from the fusible link. Failure to remove

this will render the damper inoperable.

Installation should always take into account the requirement to

provide future access for testing and maintenance, by fitting

appropriately positioned and sized access doors.

NCA Series 100 CE marked fire dampers

Operation and maintenance manual

Page 1 of 2 - Issue A - Issued 24/03/2015

Operation

Fusible link fire dampers are passive devices, and are designed to

operate without any command from an operator or system.

Fusible links will split, closing the damper when the temperature

inside the duct reaches that embossed on the link body.

The use of electromagnets or solenoids enables the damper to be

closed remotely, however they will still close when the link’s rated

temperature is reached.

Once the damper has been shut, it can only be reset manually.

Once a fusible link has split, it must be replaced with a new unit.

Spares

An amount of spare fusible links should be kept on site.

Thank you for purchasing an NCA Series 100 fire damper.

Please ensure the following information is read, understood and

followed at all stages of the damper’s life.

Maintenance information and checklist overleaf >>>