www.h-v-c.com

Operation and maintenance manual

NCA Series 400H hand operated single blade leakage rated fire damper

Regular inspection and maintenance of fire dampers is essential to

ensure they remain in good working condition. It is the system owner’s

responsibility to ensure this is carried out.

In accordance with EN 15650:2010 fire damper maintenance routines,

such as that given below, must be carried out at intervals not exceeding 6

months.

Some automatic systems may allow more frequent testing (48 hours or

less) and this may be required by national regulation.

Please note: This document is relevant only to hand operated S400

dampers. For S400 dampers equipped with an actuator

please see the relevant document.

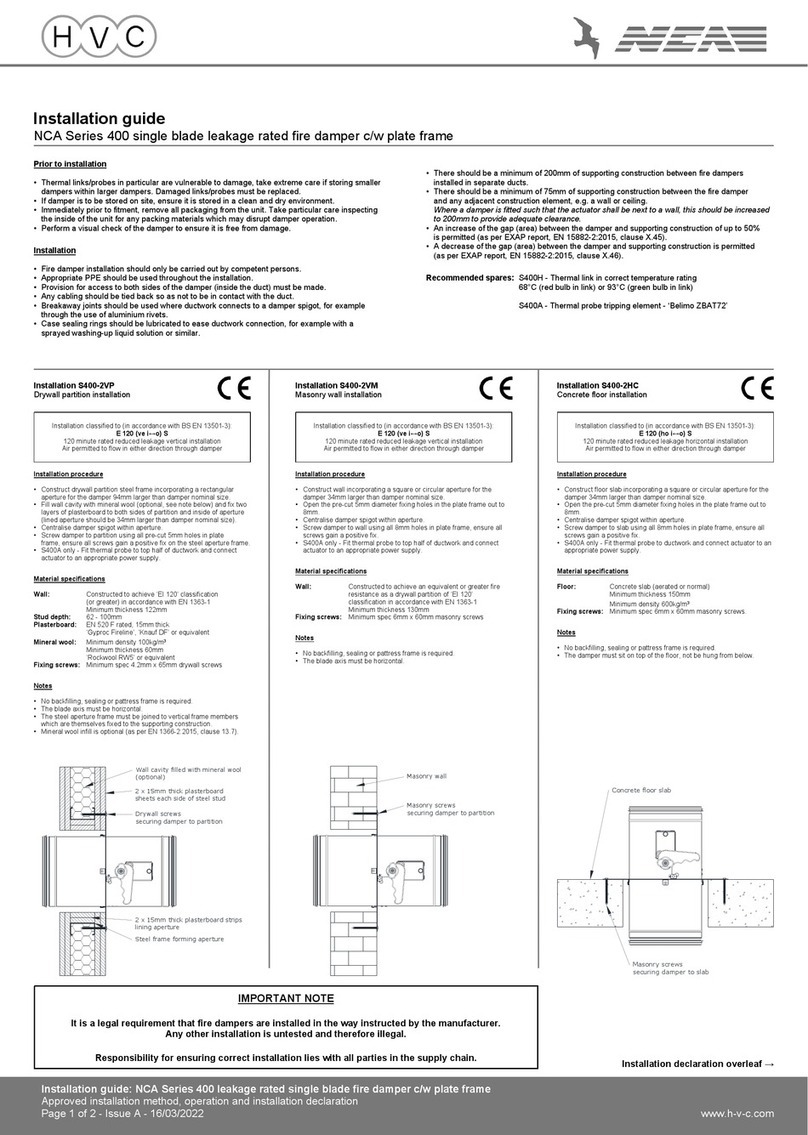

Installation guide: NCA Series 400 hand operated single blade leakage rated fire damper

Operation and maintenance manual

Page 1 of 3 - Issue A - 03/03/2022

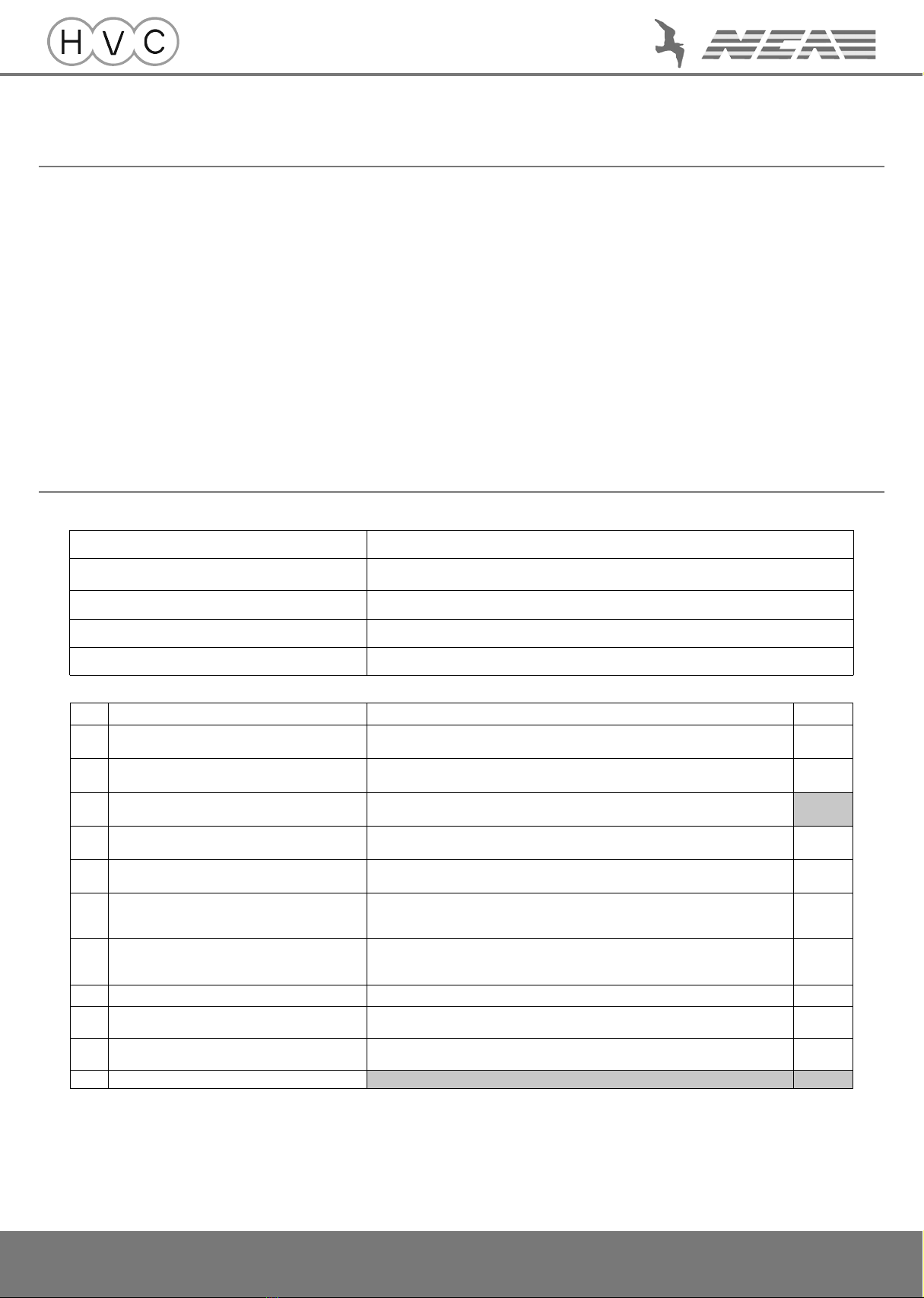

Damper type: NCA Series 400H hand operated single blade leakage rated fire damper

Thermal link rated temperature:

Delete as appropriate 68°C (red bulb in link) or 93°C (green bulb in link)

Damper reference (if applicable):

Damper location (within site):

Date of inspection:

Step Operation Notes Yes/No

1Is the damper open? The damper handle should be parallel with the damper body, indicating the

damper is open

2Is the handle mechanism secure and

undamaged?

Using a pozi-drive screwdriver, ensure the machine screw inside the spindle

cap is secure

3Remove access door/s to access the inside of

ductwork and damper blade

Both sides of the damper blade should be easily accessible N/A

4Is the damper blade in the fully open position

and secure?

The damper blade should be in the fully open position.

Gently try to move the blade by hand, it should not rotate.

5Is the damper blade unobstructed? Ensure there is nothing present which is obstructing or could obstruct the

damper blade operating

6Is the thermal link clean and free from

damage and corrosion?

Thermal links must be cleaned with care and if damaged or heavily soiled

must be replaced

Caution - Thermal links are fragile

7Is the damper blade and case clean and free

from damage and corrosion?

Use a damp cloth, brush or vacuum cleaner to remove any dirt and debris.

If damaged or corroded dampers must be replaced

Caution - Blade sealing fabric is sharp, PPE should be used

8Does the damper close correctly? Pull the test handle on the external mechanism, the damper should close

9Does the damper open correctly? Rotate the setting handle 90° anti-clockwise until the underside of the handle

latches onto the thermal link

10 Do you have any concerns about the

installation?

Is there anything that does not look correct, do you have any doubts etc.?

11 Refit access door/s securely N/A N/A

Periodic maintenance procedure

If any of questions 1 - 9 is answered ‘no’, or if the answer to

question 10 is ‘yes’, please see troubleshooting overleaf.