www.h-v-c.com

NCA Series 700

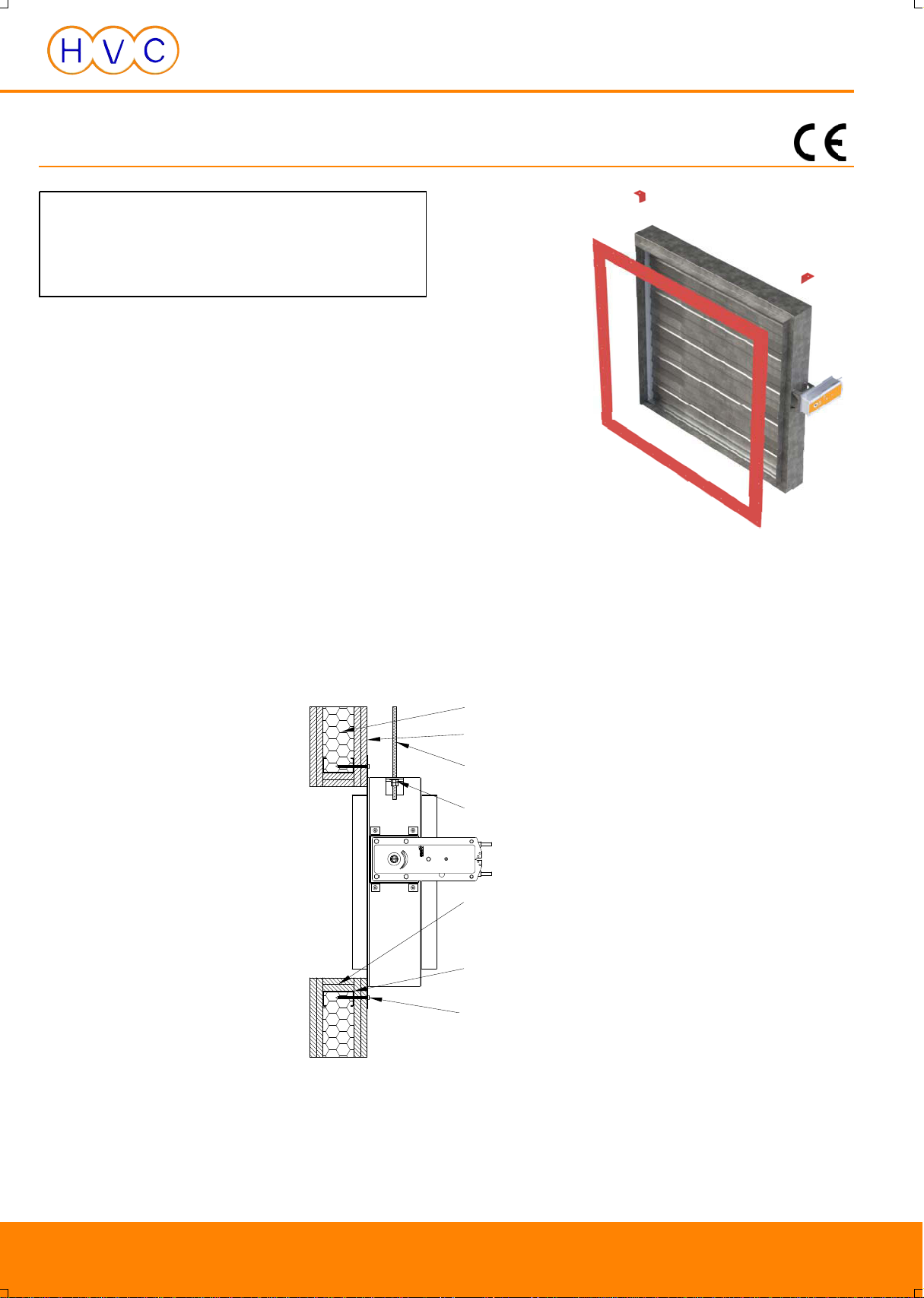

Motorised leakage rated fire dampers

NCA Series 700 fire dampers

Designed to maintain compartmentation in buildings at locations

where ductwork penetrates a fire barrier, a fire damper’s basic

function is to prevent fires spreading through ductwork.

NCA Series 700 motorised leakage rated fire dampers go beyond

this basic requirement with their reduced leakage design, making

them suitable for areas requiring dampers with ‘ES’ classification.

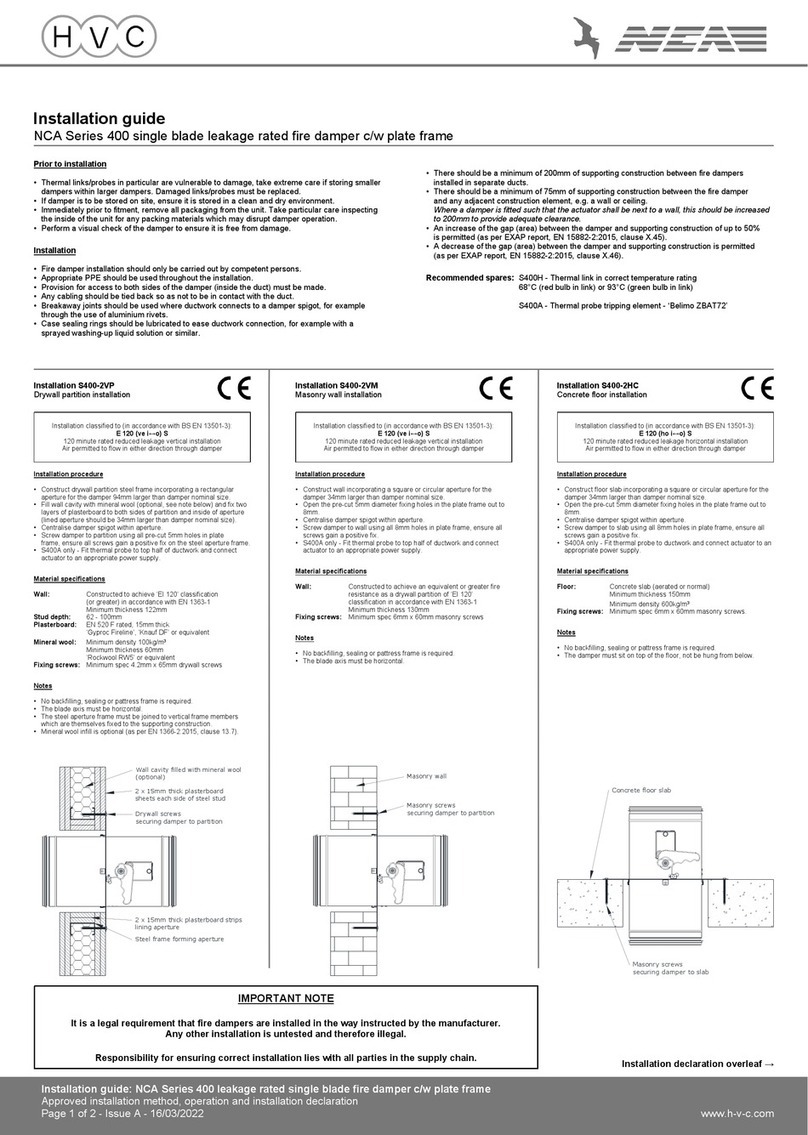

Uniquely easy to install, S700 fire dampers are surface mounted,

making use of fixing lugs and a simple plate frame with factory

punched fixing holes, installations require no backfilling, sealing or

pattress frames. This makes them especially useful for

refurbishment projects where disruption needs to be minimised.

S700 fire dampers are currently available with 120 minute rated

installations to suit drywall partitions, masonry walls and concrete

floor slabs (single sections only). All installations are classified ‘i↔o’

meaning air is permitted to flow in either direction through the

damper.

Actuators are Belimo BF series, are available in 24 or 230 volt

variants and are supplied with a 72°C rated thermal probe.

Design features

Materials Plate frame - 1.5mm galvanised steel

Case, internal frame and actuator mounting bracket - 1.2mm galvanised steel

Blades - 0.7mm galvanised steel (double layered)

Frame side, top and bottom seals - 0.4mm stainless steel (grade 301)

Drive system - Steel throughout (BZP coated)

Sizes Minimum: 200mm x 200mm / 200mm diameter nominal

Maximum: Single section - 1000mm x 1000mm / 1000mm diameter nominal

Multiple section - 2074mm x 2074mm / 2074mm diameter nominal

Units requiring a nominal width/height/diameter of less than 200mm can be supplied using reducing spigots

Operation Opposed blade, linkage driven (out of airstream)

Controls Single section assemblies: Belimo BF24-TN or BF230-TN actuator (power open, spring return, non-modulating)

complete with 72°C thermal probe

Multiple section assemblies: Belimo BF24 actuators (power open, spring return, non-modulating) complete with

relay box assembly (24V or 230V supply) with 72°C thermal probe

4