CONTENT

1 Summary ........................................................................................................................................

1

1.1 Model introduction ..............................................................................................................................1

1.2 Features .............................................................................................................................................. 1

1.3 Usage .................................................................................................................................................. 1

1.4 Symbols Introduction ........................................................................................................................... 1

1.5 Safety attentions ..................................................................................................................................1

2 Working condition and environment ...............................................................................................

2

2.1 Operation place ................................................................................................................................... 2

2.2 Power supply .......................................................................................................................................2

3 Technical Parameters ......................................................................................................................

2

4 Products system introduction ..........................................................................................................

3

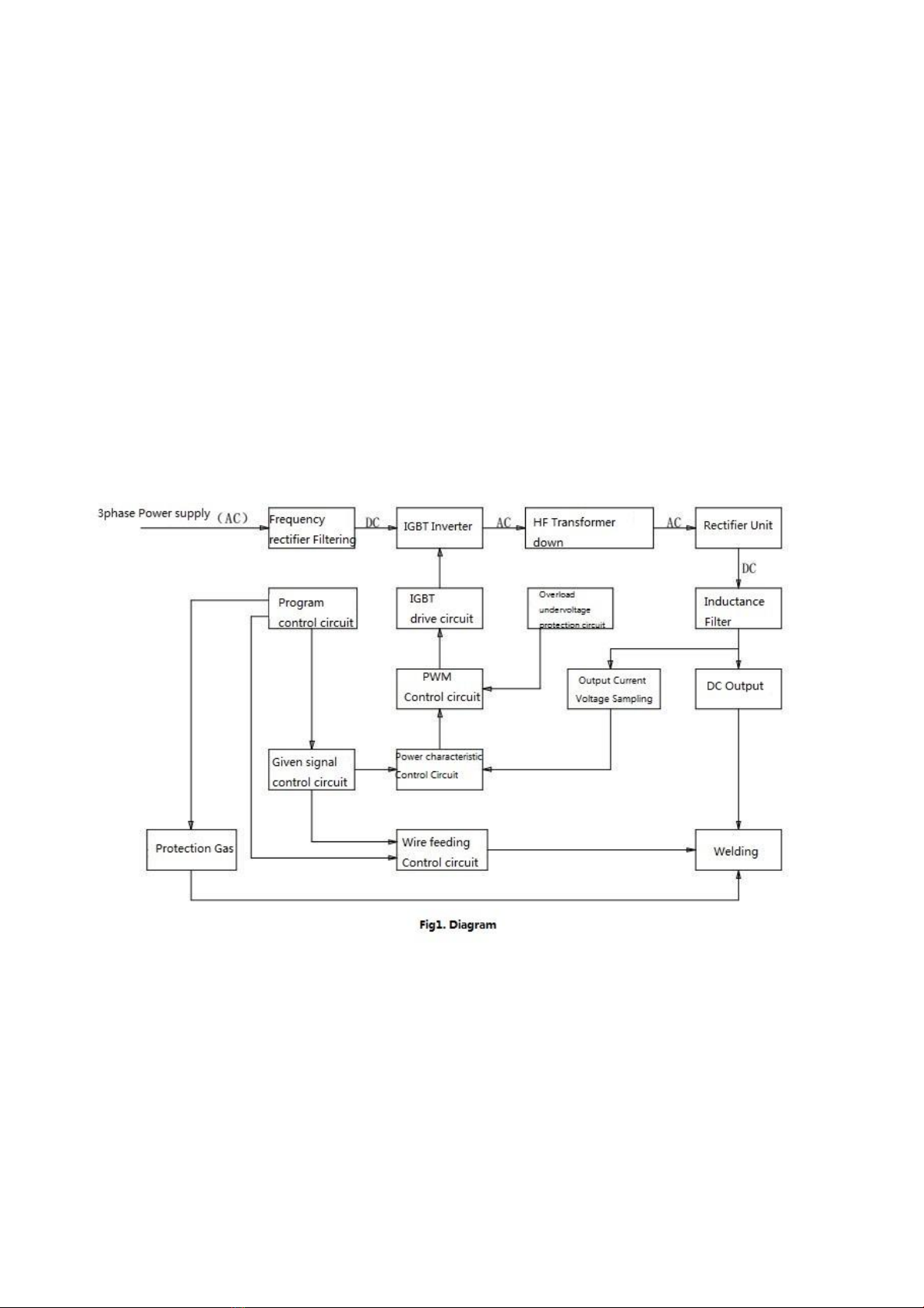

4.1 Summarize of working principles ..........................................................................................................3

4.2 Main electric diagram .......................................................................................................................... 3

4.3 Block schematic diagram ......................................................................................................................3

5 Panel function introduction .............................................................................................................

4

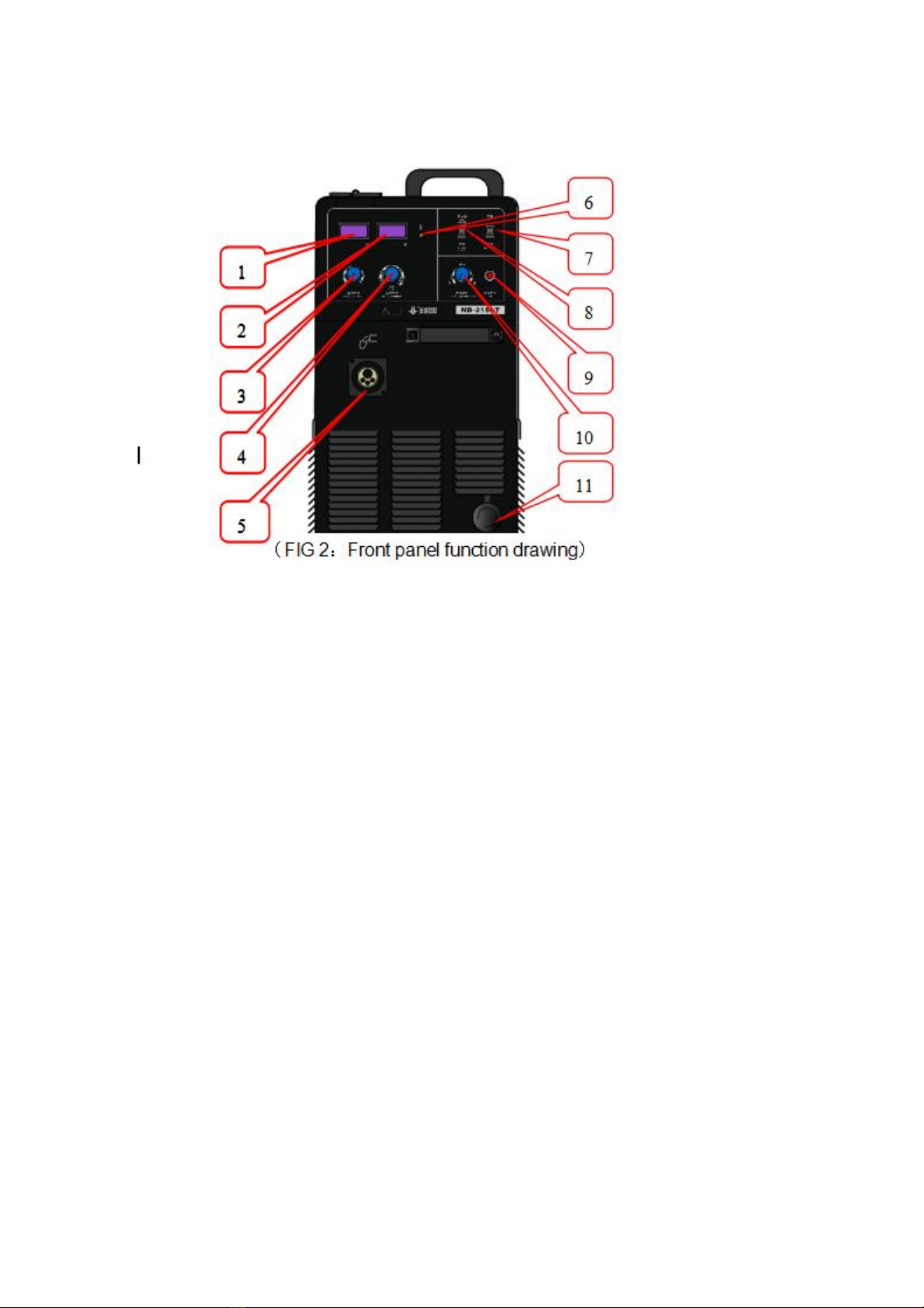

5.1 Front Panel function drawing ............................................................................................................... 4

5.2 Rear Panel Function Drawing ................................................................................................................5

Gas bottle bracket(Optional)introduction and installation drawing ............................................................. 5

6 Installation .....................................................................................................................................

7

6.1 Power supply: ...................................................................................................................................... 7

6.2 Installation (please refer to figure 8) .....................................................................................................7

7 Operation .......................................................................................................................................

7

7.1 Operating instructions ..........................................................................................................................7

7.2 Matters need attention ........................................................................................................................ 8

8 Maintenance and repairing .............................................................................................................

9

8.1 Matters need attention ........................................................................................................................ 9

8.2 Maintenance ....................................................................................................................................... 9

8.3 Trouble shooting ..................................................................................................................................9

8.4 Main parts list ..................................................................................................................................10

9 Packing list ..................................................................................................................................

13

10 Drawing ....................................................................................................................................

14